Screening method of termite-source forage bacillus

A Bacillus and screening method technology, which is applied in the field of screening of termite-derived feedable Bacillus, can solve the problems of heavy re-screening workload, high cost, and difficult operation, and achieve reduced re-screening workload, improved efficiency, and reduced The effect of screening costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] In this embodiment, the medium formula used is as follows:

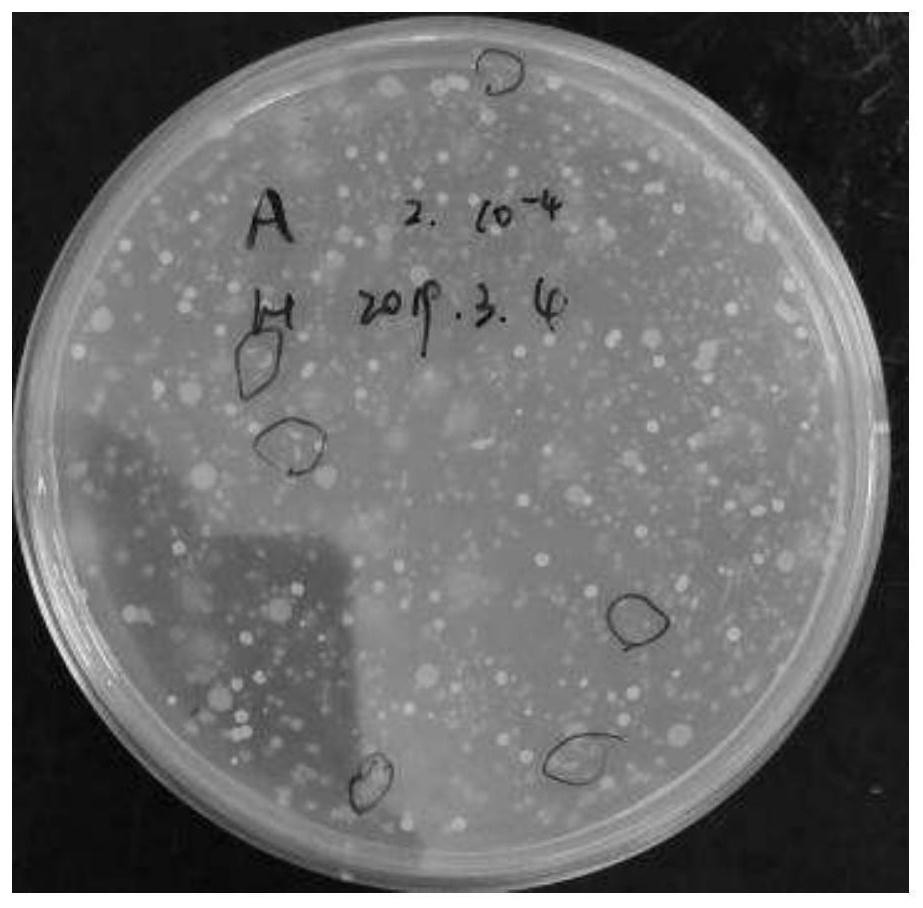

[0030] i. Primary screening medium: CMC-Na 10.0g, peptone 2.0g, K 2 HPO 4 4.0g, (NH 4 ) 2 SO 4 2.0g, MgSO 4 ·7H 2 O 0.3g, agar 15.0g, dilute to 1000mL with distilled water, pH=6.5.

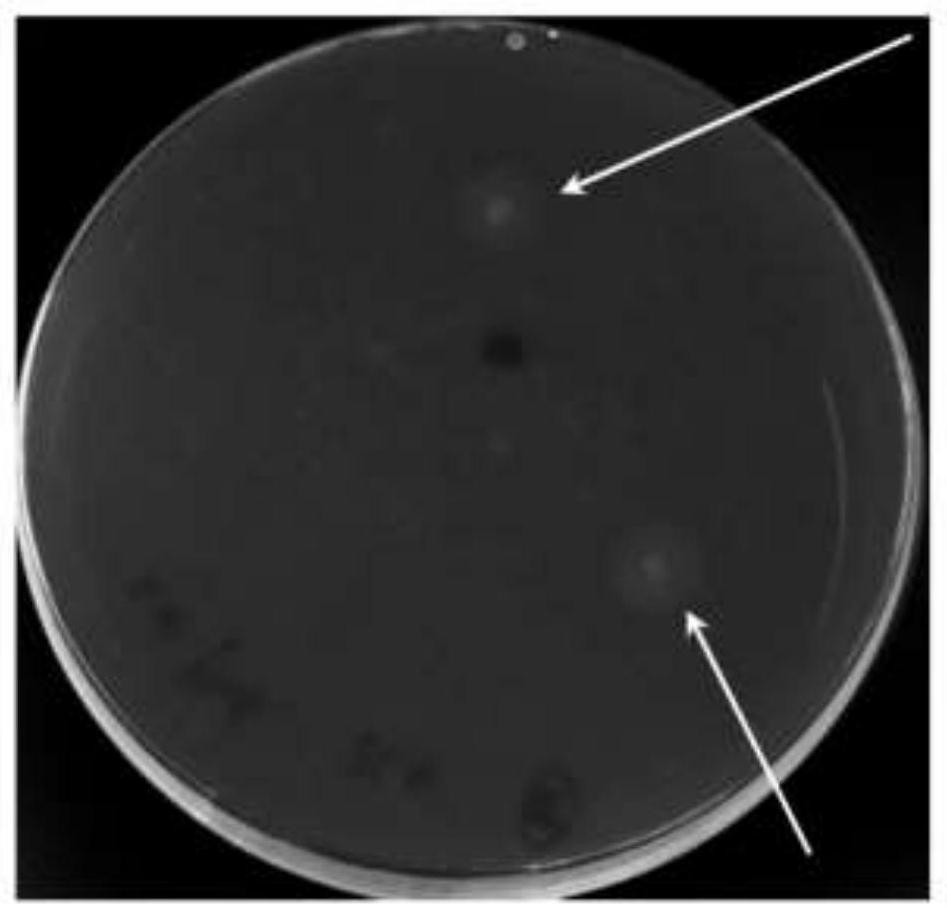

[0031] ii. Re-screening medium: CMC-Na 10.0g, peptone 2.0g, K 2 HPO 4 4.0g, (NH 4 ) 2 SO 4 2.0g, MgSO 4 ·7H 2 O 0.3g, Congo red 0.4g, agar 15.0g, dilute to 1000mL with distilled water, pH=6.5.

[0032] iii. Fermentation enzyme production medium: CMC-Na 10.0g, peptone 2.0g, K 2 HPO 4 4.0g, (NH 4 ) 2 SO 4 2.0g, MgSO 4 ·7H 2 O 0.3g, dilute to 1000mL with distilled water, pH=6.5.

[0033] iv. DNS solution: KNaCHO 6 4H 2 O 182.0g, NaOH 20.96g, DNS 6.3g, PhOH 2.5g, NaOH 2 SO 3 5.0g. Dilute to 1000mL with distilled water.

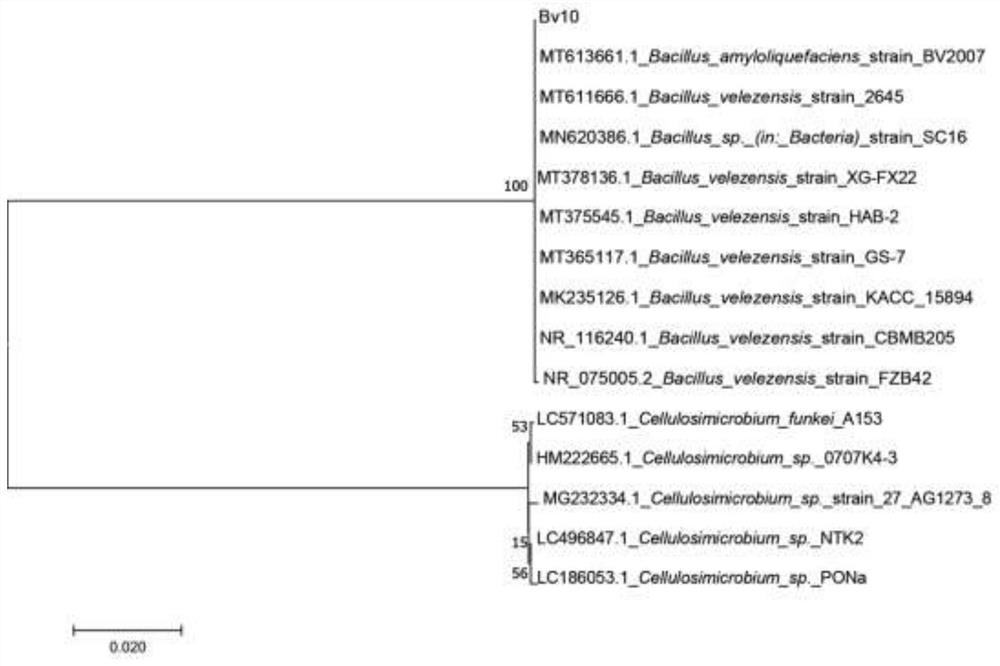

[0034] A kind of screening method of feedable bacillus provided by the present embodiment mainly comprises the following steps:

[0035] (1) Grinding termites: first wash the termites ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com