Molten salt treatment system and process

A processing system and molten salt technology, applied in the field of molten salt processing systems and processes, can solve problems such as difficulty in removing salt, difficulty in removing salt, and limited industrial use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

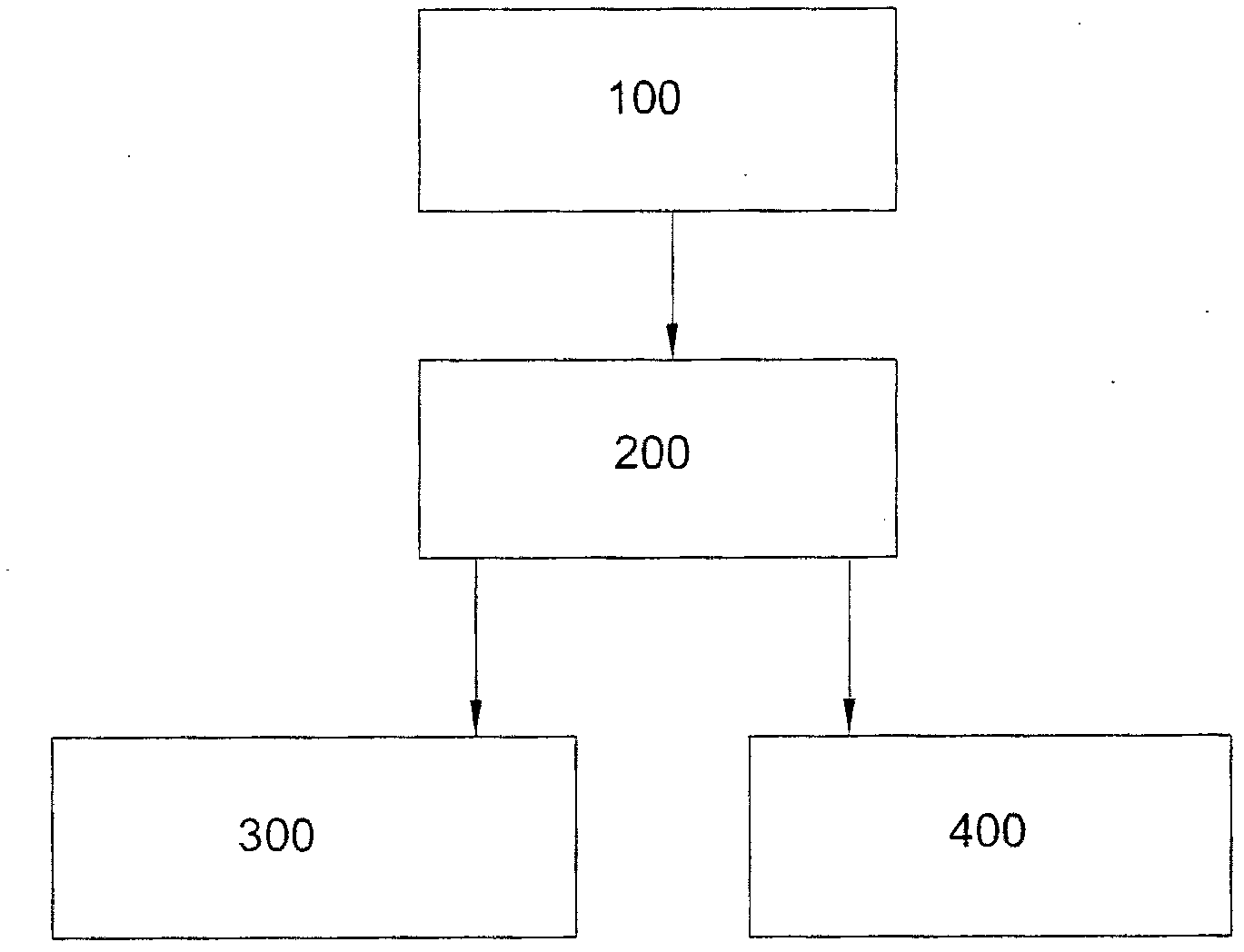

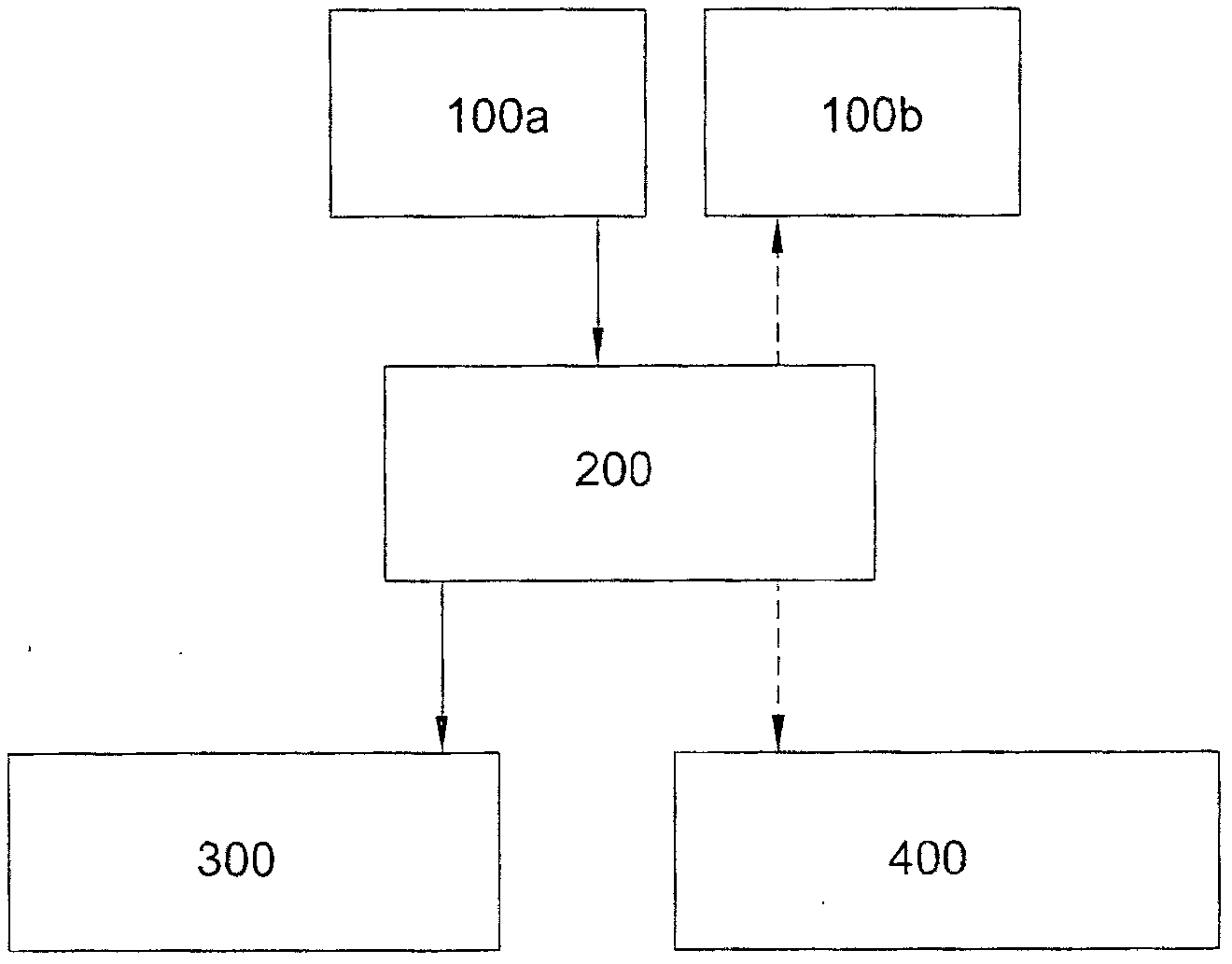

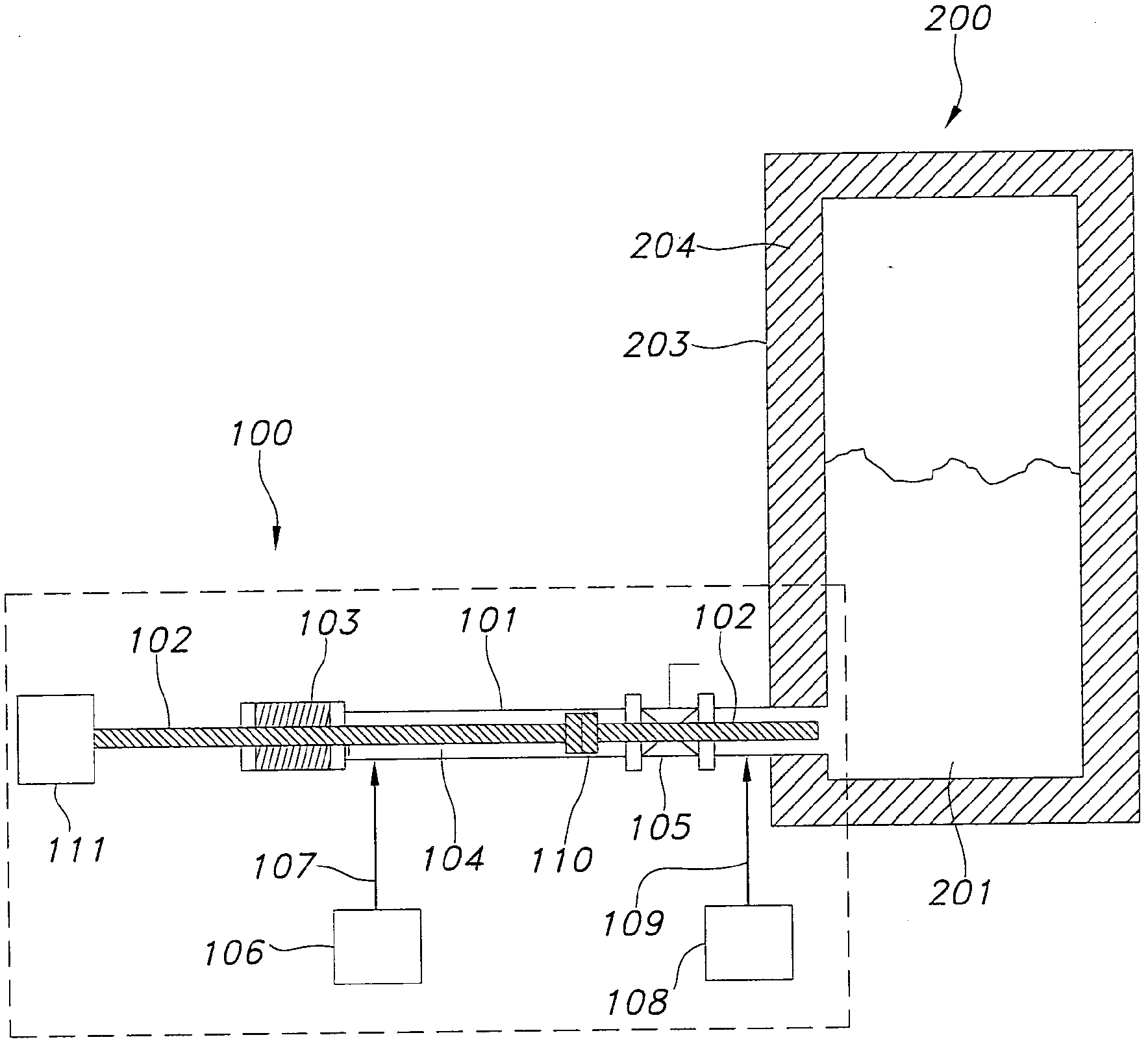

[0208] The molten salt treatment system according to the invention can be used, especially as a molten salt oxidation (MSO) reactor. MSO technology is a thermal process capable of destroying the organic components of mixed waste, hazardous waste, and energetic materials while retaining the inorganic components of the salt.

[0209] Molten salt oxidation is a flameless thermal process that can be described as the addition of a liquid or solid feed and excess air or oxygen-containing gas to a salt or salt mixture such as sodium carbonate (Na 2 CO 3 ) and sodium chloride (NaCl)) in a molten salt bath in which organic materials are oxidized to mainly carbon dioxide and water in the molten salt. Typically, the waste stream is introduced below the liquid level of the molten salt, but it can be introduced above the surface. The choice of salt for an MSO system is highly dependent on the type of feed to be treated; if sour gas treatment is desired, it would be desirable to include a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com