Passive residual heat exhausting system for molten salt reactor

A passive waste heat, molten salt reactor technology, applied in reactors, nuclear power generation, greenhouse gas reduction, etc., can solve problems such as economic decline, inconvenient maintenance, and increased failure rate of system equipment, reducing system equipment and improving inherent safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in more detail below in conjunction with accompanying drawing example:

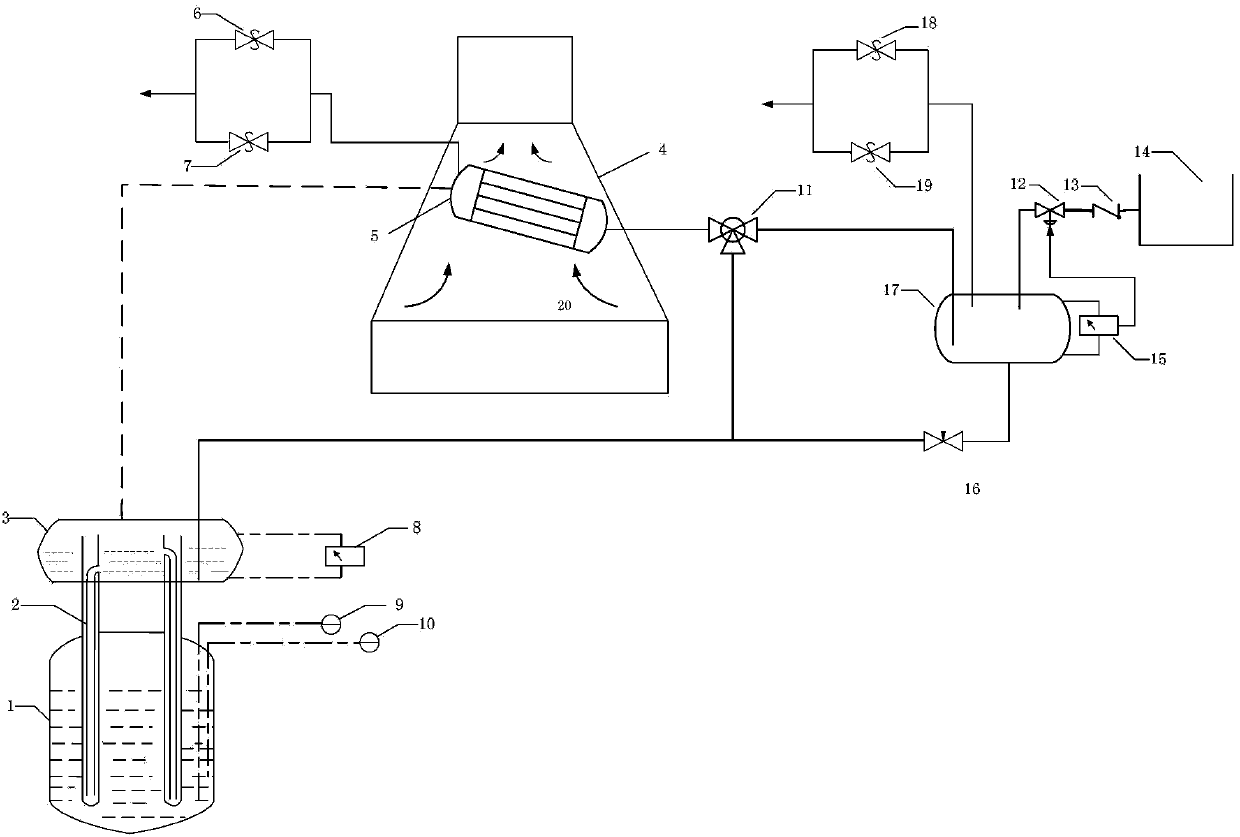

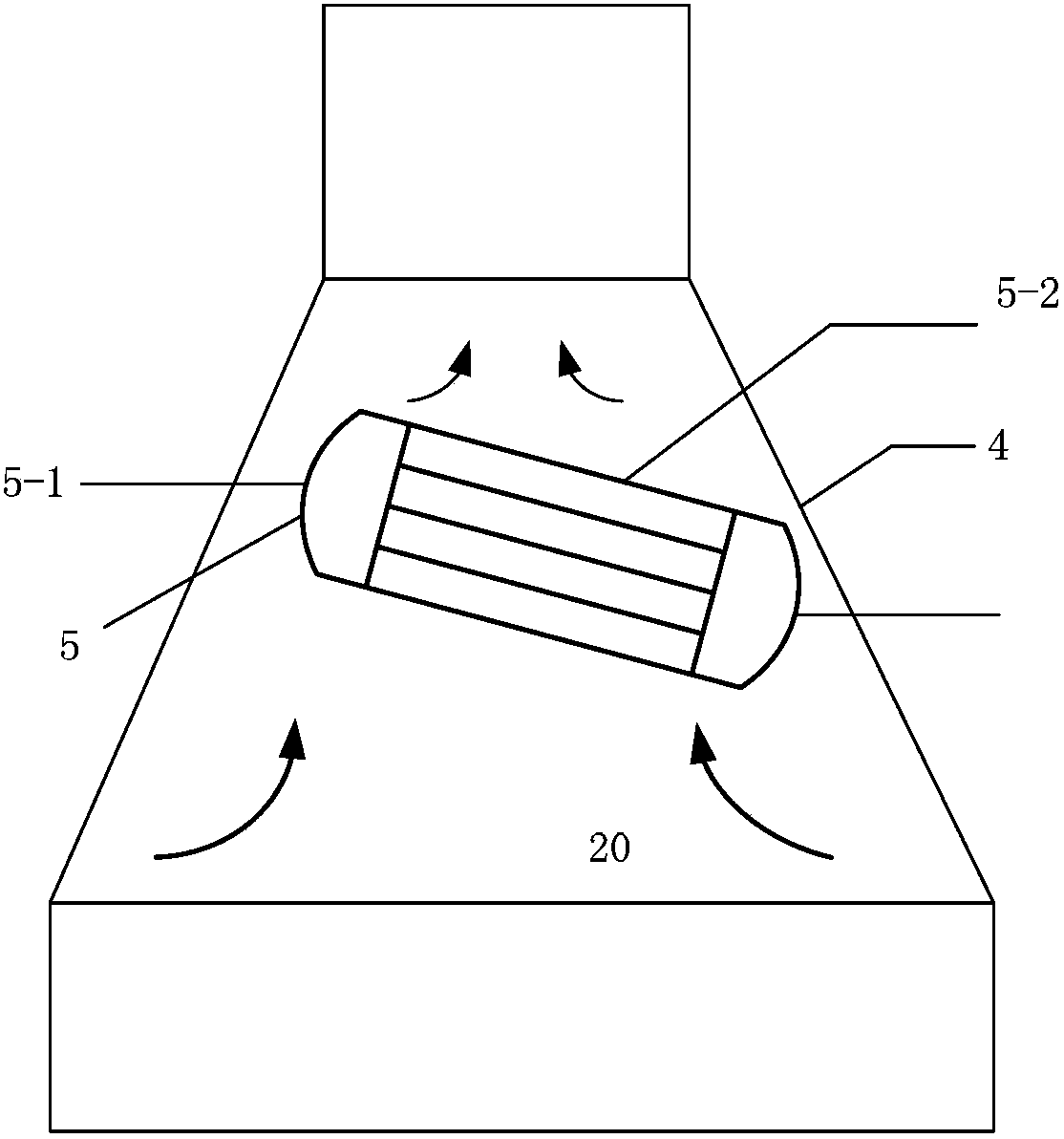

[0025] combine Figure 1~5 , the present invention mainly includes a salt discharge tank 1, a heat exchange element 2, a steam drum 3, an air cylinder 4, an air cooler 5, a water supply tank 17, a water supply tank 14, and related valves 6, 7, 11, 12, 13, 16, 18, 19, temperature sensors 9, 10, liquid level sensors 8, 15 and piping system.

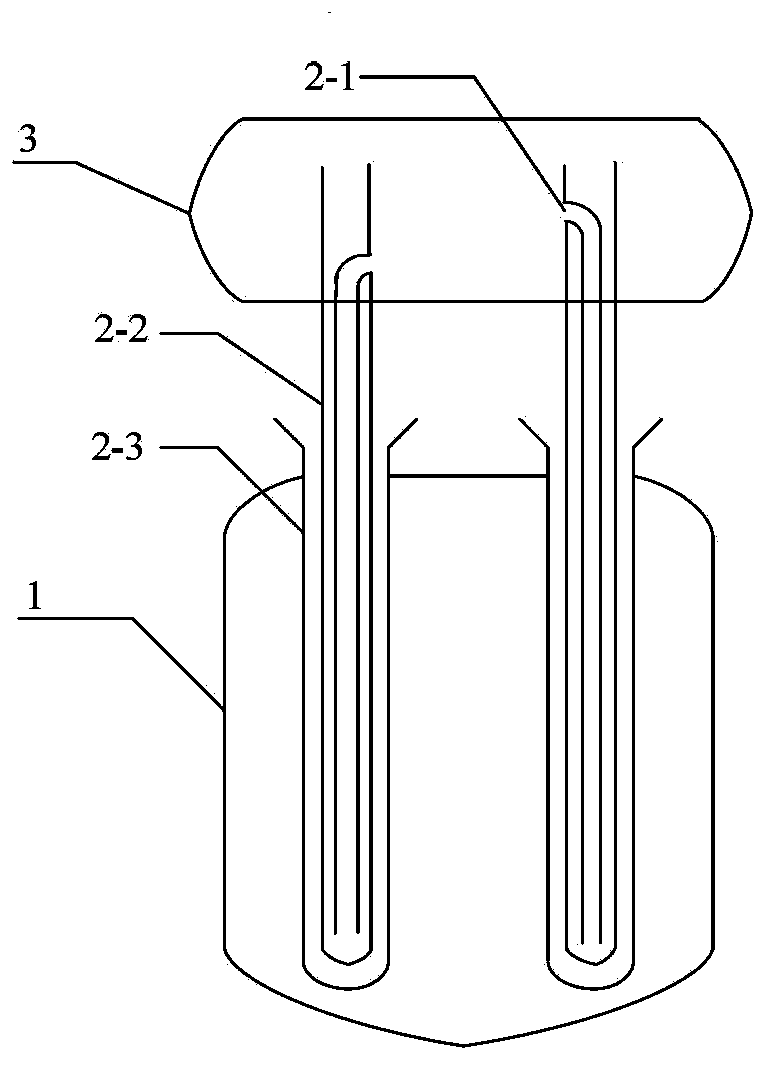

[0026] The main body of the salt discharge tank 1 is a cylindrical structure made of INOR-8 nickel-based alloy, which is used to store molten salt that can continue to generate decay heat. The volume of the salt discharge tank 1 determines that the fuel salt cannot be stored in the tank. When the critical point is reached, a heat exchange element guide pipe, that is, the outermost casing of the heat exchange element 2, is arranged in the salt discharge tank 1 .

[0027] The heat exchange element 2 is a casing structure. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com