Residual heat removal system for molten salt reactor buffer salt accident

A waste heat removal system and buffer salt technology, applied in reactors, greenhouse gas reduction, nuclear engineering, etc., can solve the problems of large equipment space and low heat exchange efficiency, and achieve space saving, prolong service life, and improve cooling capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

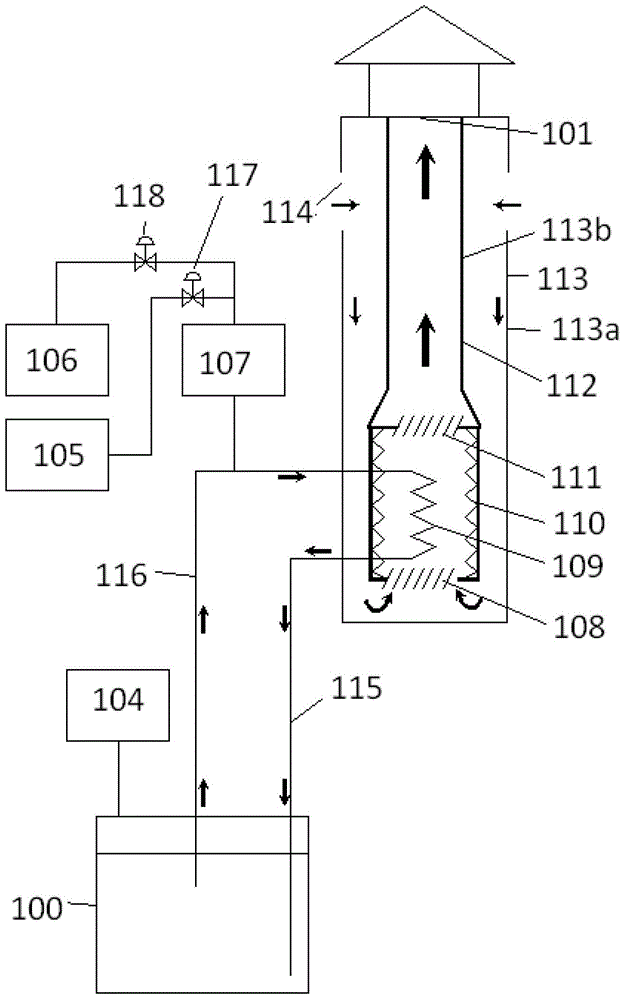

[0025] According to an embodiment of the present invention, the molten salt reactor buffer salt accident waste heat removal system is as follows: figure 1 As shown, it includes a molten salt pool 100, an air cooling tower 113 and a main loop system therebetween. The reactor core is located in a molten salt pool 100 filled with molten salt. The waste heat of the reactor core is transferred to the main circuit system through the molten salt, and the heat is transferred to the air cooling tower 113 through the main circuit system, and the heat is transferred to the final heat sink—atmosphere.

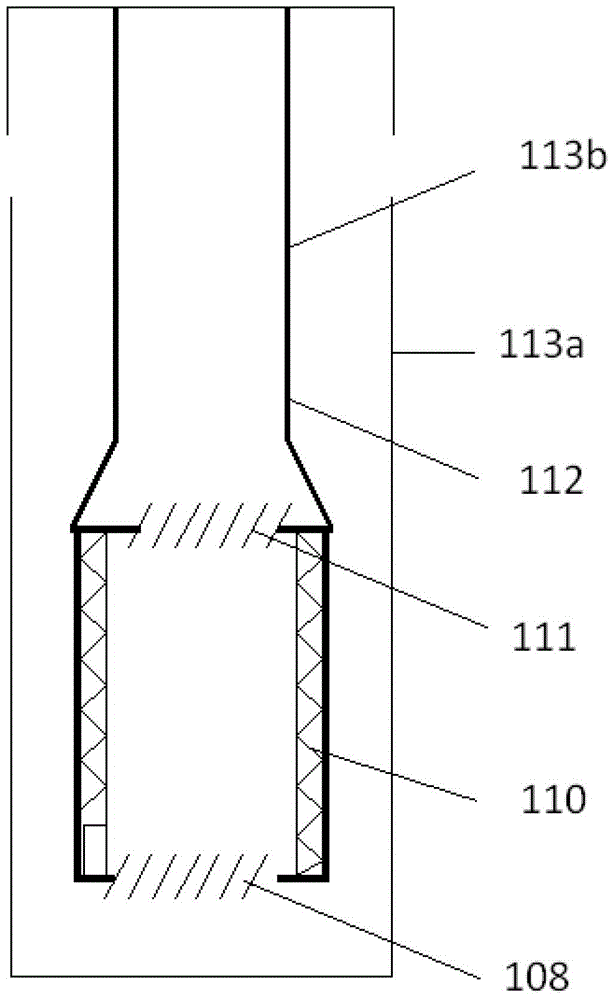

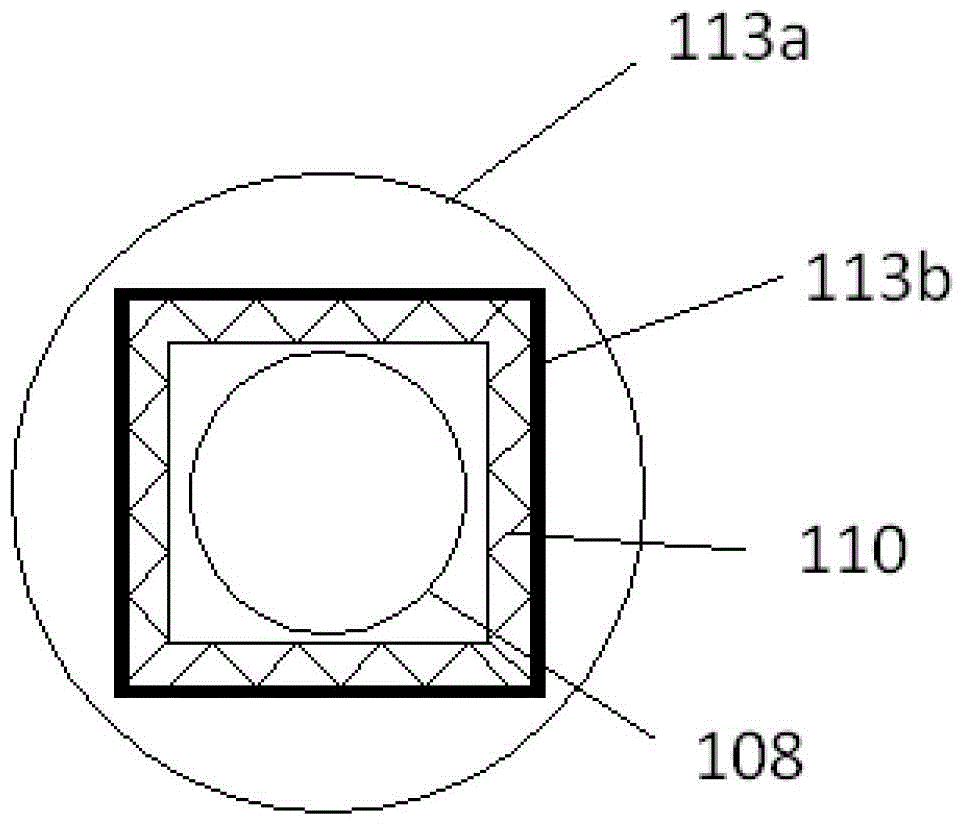

[0026] The air cooling tower 113 has an outer wall 113a and an inner wall 113b radially spaced apart from each other, such as figure 2 shown. The lowest point of the inner wall 113 b is kept spaced from the bottom of the air cooling tower 113 . The air inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com