Method for plating tungsten on diamond powder surface

A diamond powder and body surface technology, which is applied in gaseous chemical plating, metal processing equipment, metal material coating technology, etc., can solve the problem of limited powder quantity, and achieve the effect of simple equipment, high purity of coating, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

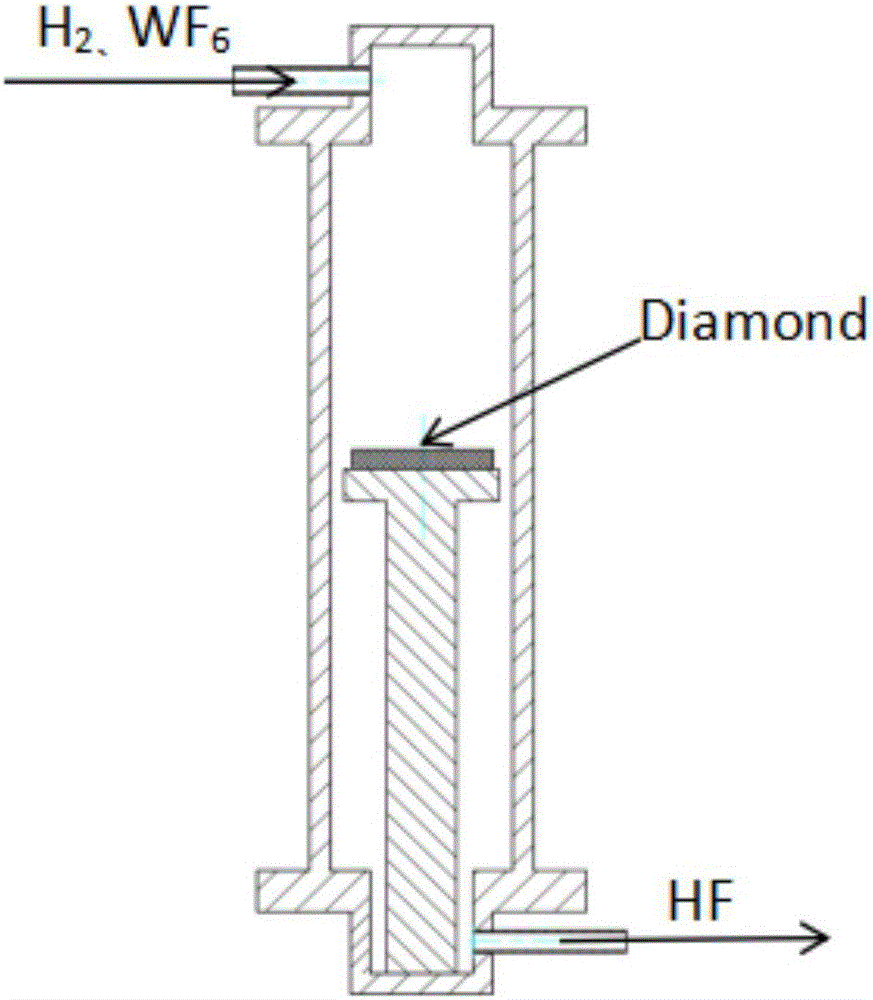

Method used

Image

Examples

Embodiment 1

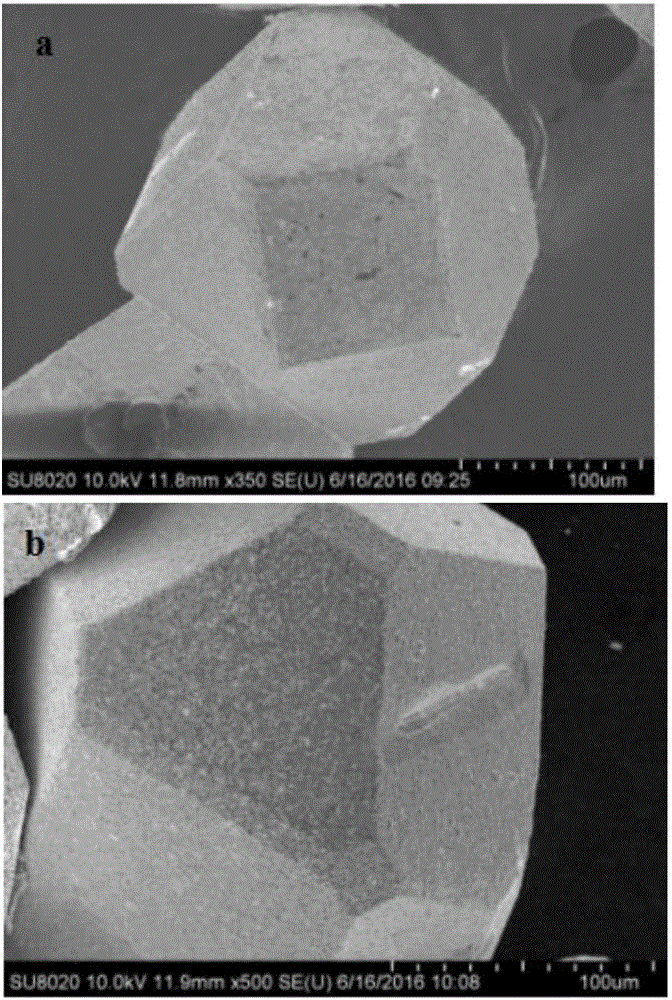

[0026] Spread about 2g of the dried diamond particles evenly on the heating platform, then put the platform in the heating furnace, heat the temperature to 550°C in a hydrogen atmosphere and keep it for 0.5h; press H 2 The flow rate is 1L / min, WF 6 Reactive gas was introduced at a flow rate of 1g / min; the platform was kept vibrating during the deposition process. Turn off WF after 2min reaction 6 Incubate for another 0.5h. After slowly cooling to room temperature, take out the diamond powder. Observed at low magnification, it is found that the tungsten coating is uniform and compact (thickness about 5um), the coating structure is single, and the coating has high purity.

Embodiment 2

[0028] Spread about 2g of the dried diamond particles evenly on the heating platform, then place the platform in the heating furnace, heat the temperature to 620℃ in a hydrogen atmosphere, and keep it for 0.5h, press H 2 The flow rate is 1L / min, WF 6 Consumption 2g / min, turn off WF after 2min reaction 6 Incubate for another 0.5h. Keep the platform vibrating during the deposition process. After slowly cooling to room temperature, take out the diamond powder. Observed at low magnification, it is found that the tungsten coating is uniform and compact (thickness about 10um), the coating structure is single, and it has high purity.

Embodiment 3

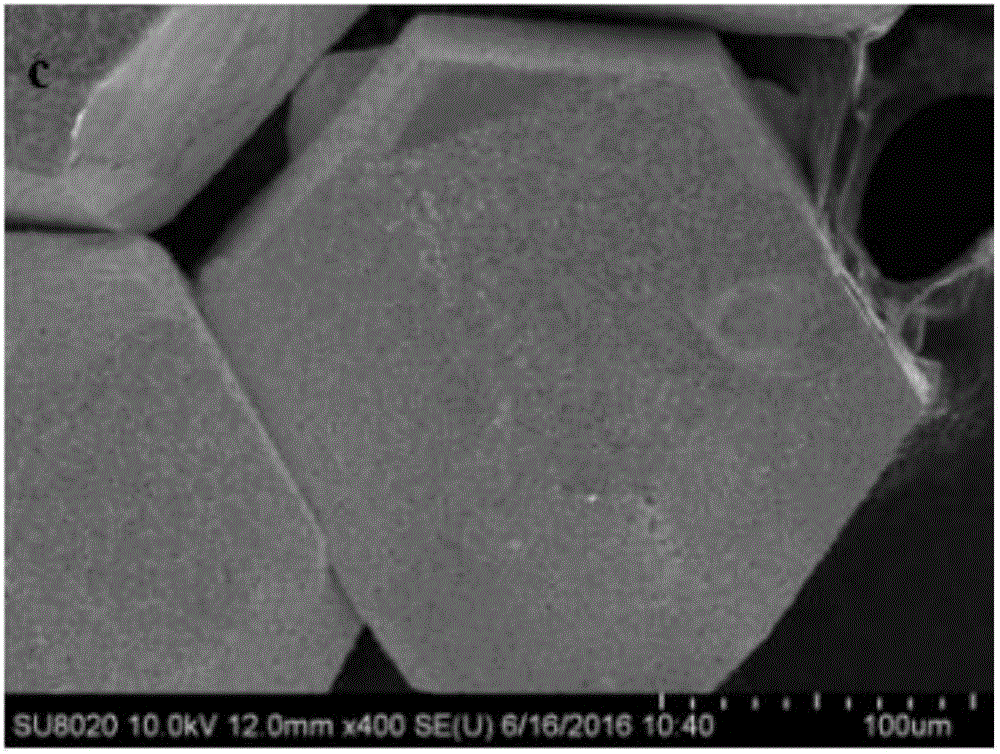

[0030] Spread about 2g of the dried diamond particles evenly on the heating platform, then put the platform in the heating furnace, heat the temperature to 700℃ in a hydrogen atmosphere, and keep it for 0.5h, press H 2 The flow rate is 1L / min, WF 6 Consumption 3g / min, turn off WF after 2min reaction 6 Incubate for another 0.5h. Keep the platform vibrating during the deposition process. After slowly cooling to room temperature, take out the diamond powder. Observed at low magnification, it is found that the tungsten coating is uniform and compact (thickness about 15um), the coating structure is single, and it has high purity.

[0031] The coating is well bonded to the substrate (such as Figure 5 ), the mass fraction after tungsten plating of Example 3 is 8.77% diamond powder and copper powder (200 mesh ~ 250 mesh) hot press sintering (sintering parameters: 760℃, 50KN, 5 minutes) 24×7× For the 6mm block, the thermal expansion coefficient of the briquette is reduced and the bendin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com