Tungsten hexafluoride gas purifying device and method

A technology of tungsten hexafluoride and purification equipment, which is applied in chemical instruments and methods, specific gas purification/separation, tungsten halide, etc., can solve the problems of HF content reduction, high raw material gas purity requirements, high production cost, etc., and achieve simplified production The effect of process, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

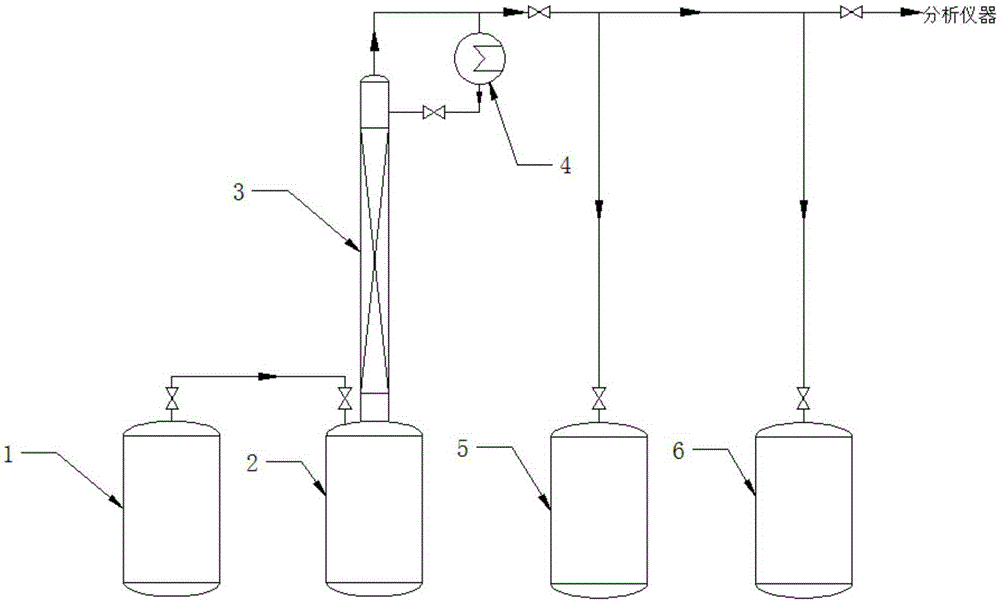

[0036]In the tungsten hexafluoride purification device used in this embodiment:

[0037] The volume of the rectification kettle 2 is 100L, the volume of the condenser 4 is 5L, the diameter of the rectification column 3 is 30mm, the height is 1500mm, and the θ ring packing with an equivalent diameter of 2mm is filled, the filling height of the packing is 1200mm, and the number of theoretical plates is 80 . The raw material storage tank 1 , rectification kettle 2 , rectification column 3 , condenser 4 , crude product storage tank 5 , fine product storage tank 6 , pipelines and fillers are made of stainless steel.

[0038] A method for purifying tungsten hexafluoride, the method is purified using a purification device for tungsten hexafluoride described in this embodiment, and the steps are as follows:

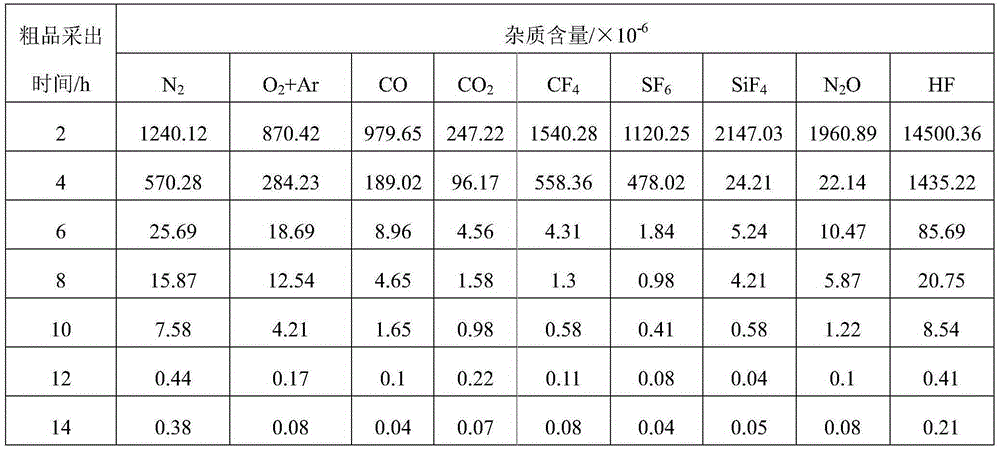

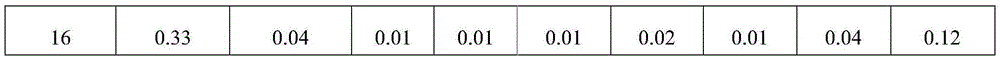

[0039] 140kg of crude tungsten hexafluoride with a purity of 90% and a volume percentage of HF of 5.25% in the raw material storage tank 1 was passed as a raw material into the ...

Embodiment 2

[0049] In the tungsten hexafluoride purification device used in this embodiment:

[0050] The rectification kettle 2 has a volume of 100L, the condenser 4 has a volume of 5L, the rectification column 3 has a diameter of 40mm and a height of 2500mm, and is filled with a θ ring packing with an equivalent diameter of 4mm, the filling height of the packing is 2300mm, and the number of theoretical plates is 100 . The raw material storage tank 1 , rectification kettle 2 , rectification column 3 , condenser 4 , crude product storage tank 5 , fine product storage tank 6 , pipelines and fillers are made of nickel.

[0051] A method for purifying tungsten hexafluoride, the method is purified using a purification device for tungsten hexafluoride described in this embodiment, and the steps are as follows:

[0052] 220kg of crude tungsten hexafluoride with a purity of about 80% and a volume percentage of HF of 9.98% in the raw material storage tank 1 is passed as a raw material into the r...

Embodiment 3

[0062] In the tungsten hexafluoride purification device used in this embodiment:

[0063] The volume of the rectifying kettle 2 is 200L, the volume of the condenser 4 is 10L, the diameter of the rectifying column 3 is 100mm, the height is 3500mm, and the Raschig ring packing with an equivalent diameter of 8mm is filled, the filling height of the packing is 3300mm, and the number of theoretical plates is 150. The raw material storage tank 1, rectification kettle 2, rectification column 3, condenser 4, crude product storage tank 5, fine product storage tank 6, pipelines and fillers are made of Monel.

[0064] A method for purifying tungsten hexafluoride, the method is purified using a purification device for tungsten hexafluoride described in this embodiment, and the steps are as follows:

[0065] 600 kg of crude tungsten hexafluoride with a purity of about 90% and a volume percentage of HF of 5.03% in the raw material storage tank 1 is passed as a raw material into the rectifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com