Adsorption tower for preparing high-purity tungsten hexafluoride

A technology of tungsten hexafluoride and adsorption tower, applied in the field of tungsten hexafluoride preparation, can solve problems such as affecting the adsorption effect, and achieve the effects of improving the utilization rate, increasing the contact area, and improving the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

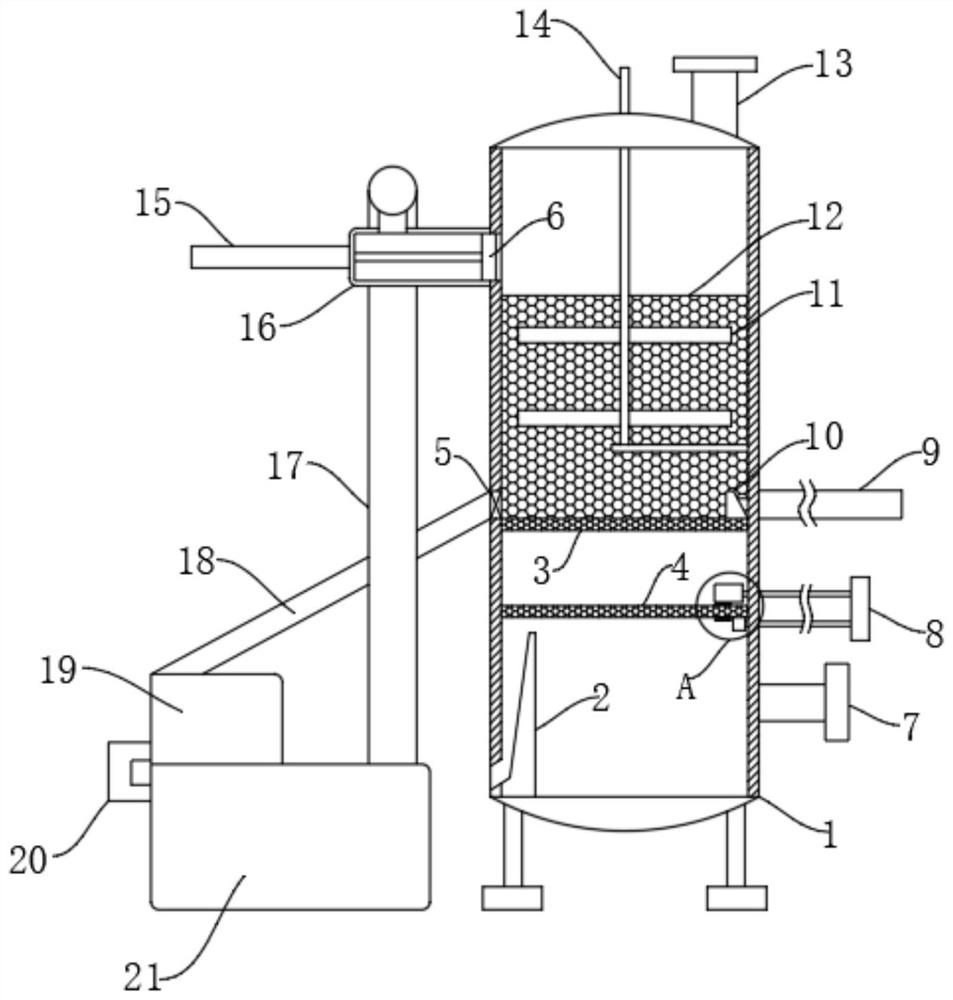

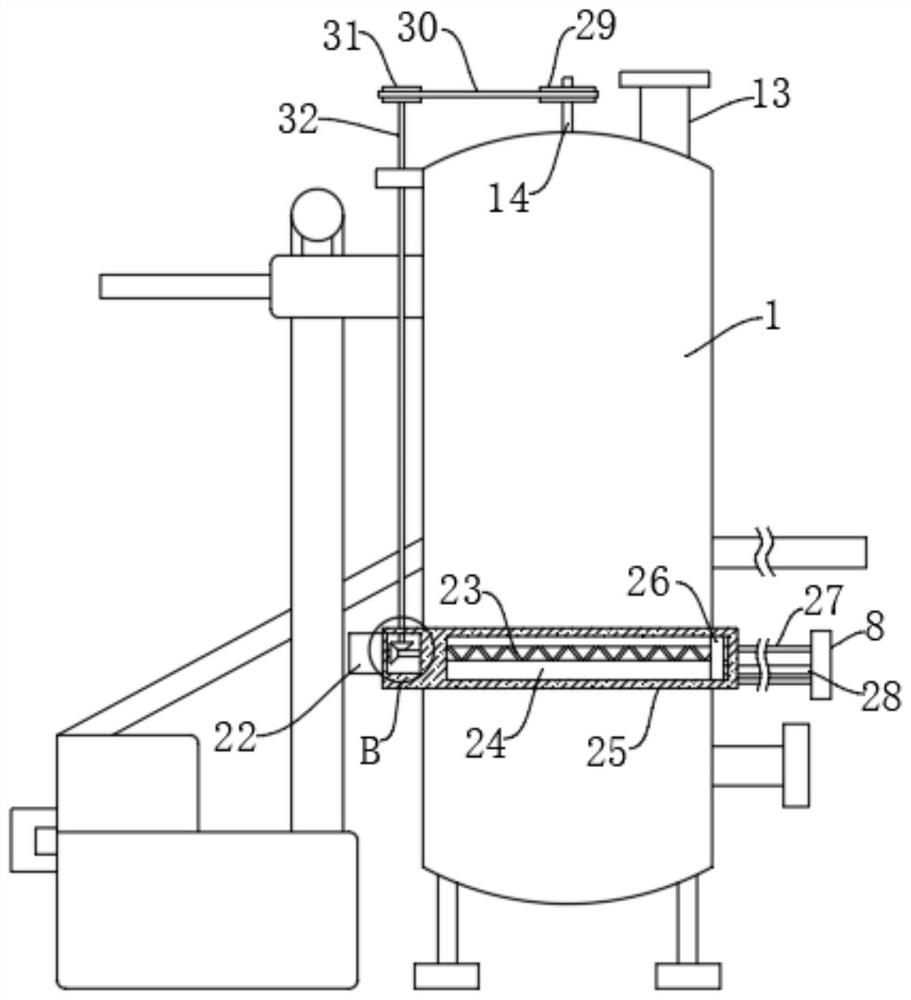

[0055] An adsorption tower for preparing high-purity tungsten hexafluoride, the adsorption tower mainly includes an adsorption tower body 1, an adsorbent, a feeding mechanism and a discharging mechanism, and may also include a recycling mechanism, a cleaning mechanism and a stirring mechanism at least one of

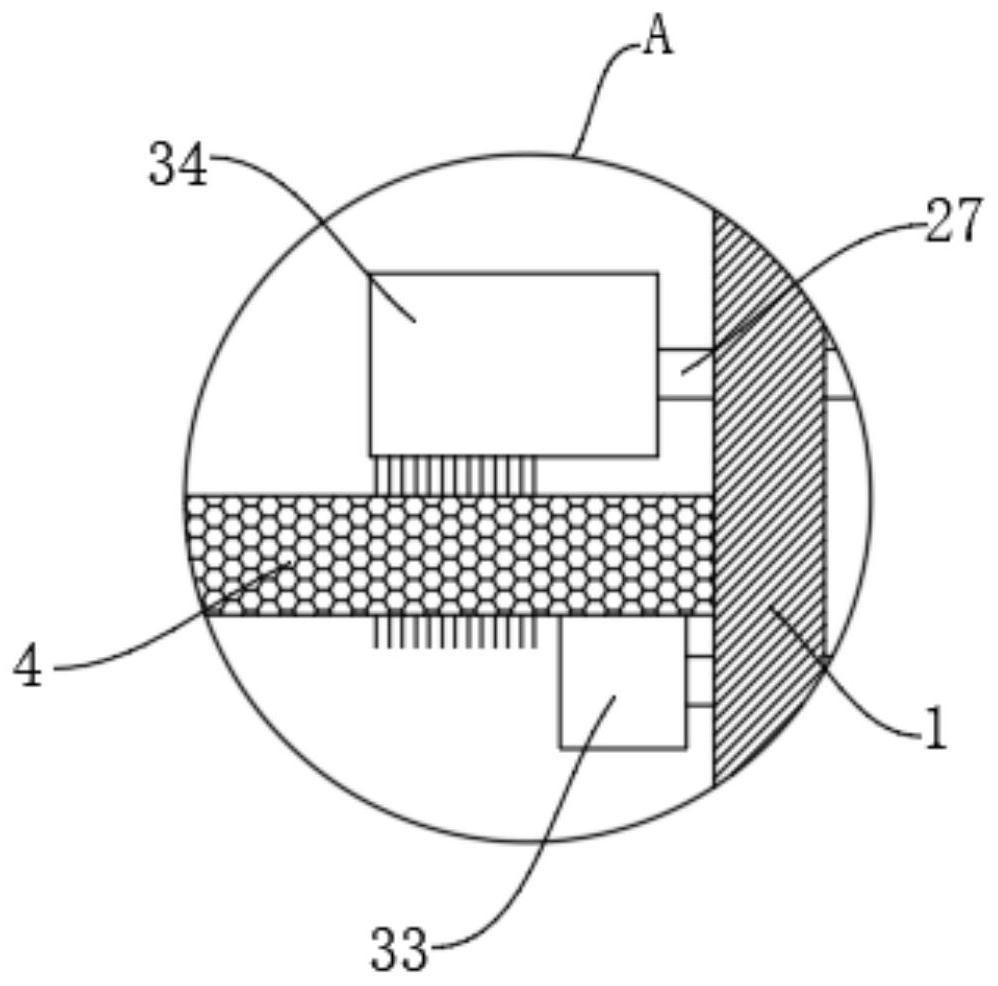

[0056] Such as figure 1 As shown, the adsorption tower body 1 is sequentially provided with a screen 3 and a filter 4 from top to bottom, the screen 3 is filled with adsorbent, and the filter 4 is used to filter the granular Impurities; intake pipe 7 is installed on the adsorption tower body 1 below filter screen 4, is provided with discharge port 5 on the adsorption tower body 1 sidewall of retaining net 3 top and next to retaining net 3 places, and discharge port A valve is installed in the 5, and a through hole is processed on the side wall of the adsorption tower body 1 opposite to the discharge port. A feed inlet and an air outlet pipe 13 are installed on the adsor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com