Method and apparatus for preparing tungsten hexafluoride using a fluidized bed reactor

A fluidized bed reactor, technology of tungsten hexafluoride, applied in chemical instruments and methods, fluoride preparation, tungsten halide, etc. Uniform distribution constraints and other issues to achieve the effect of reducing volume, increasing contact area, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

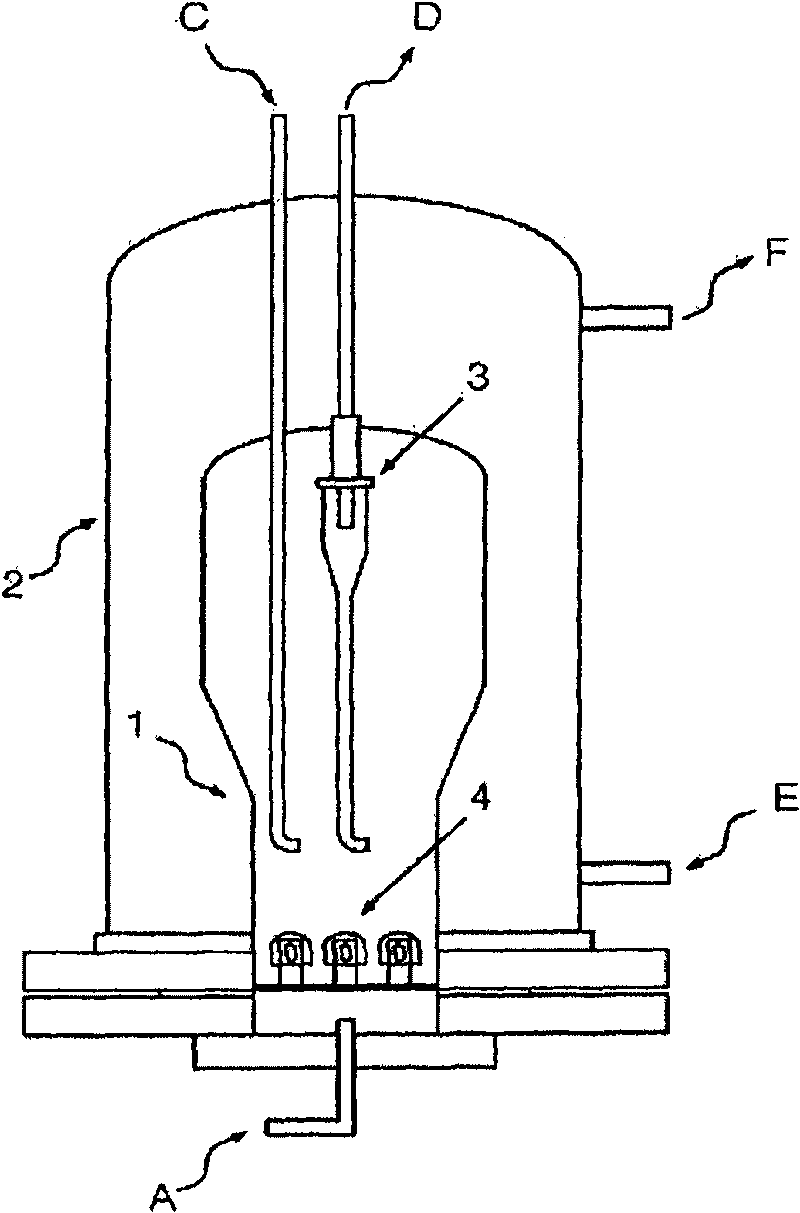

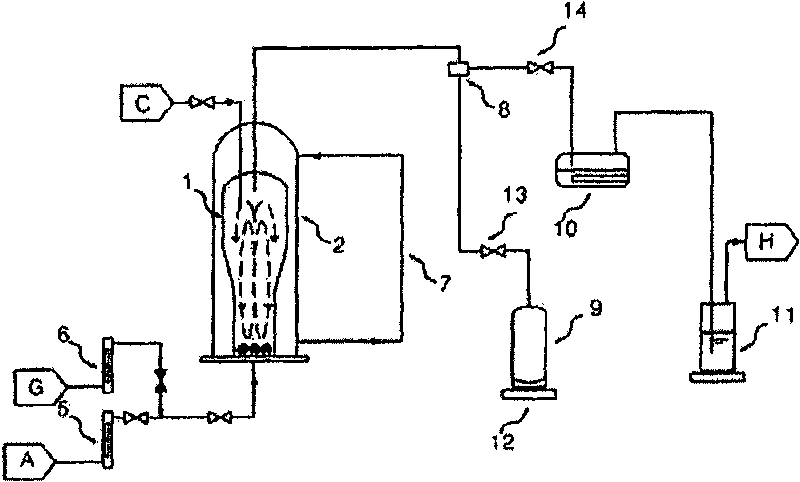

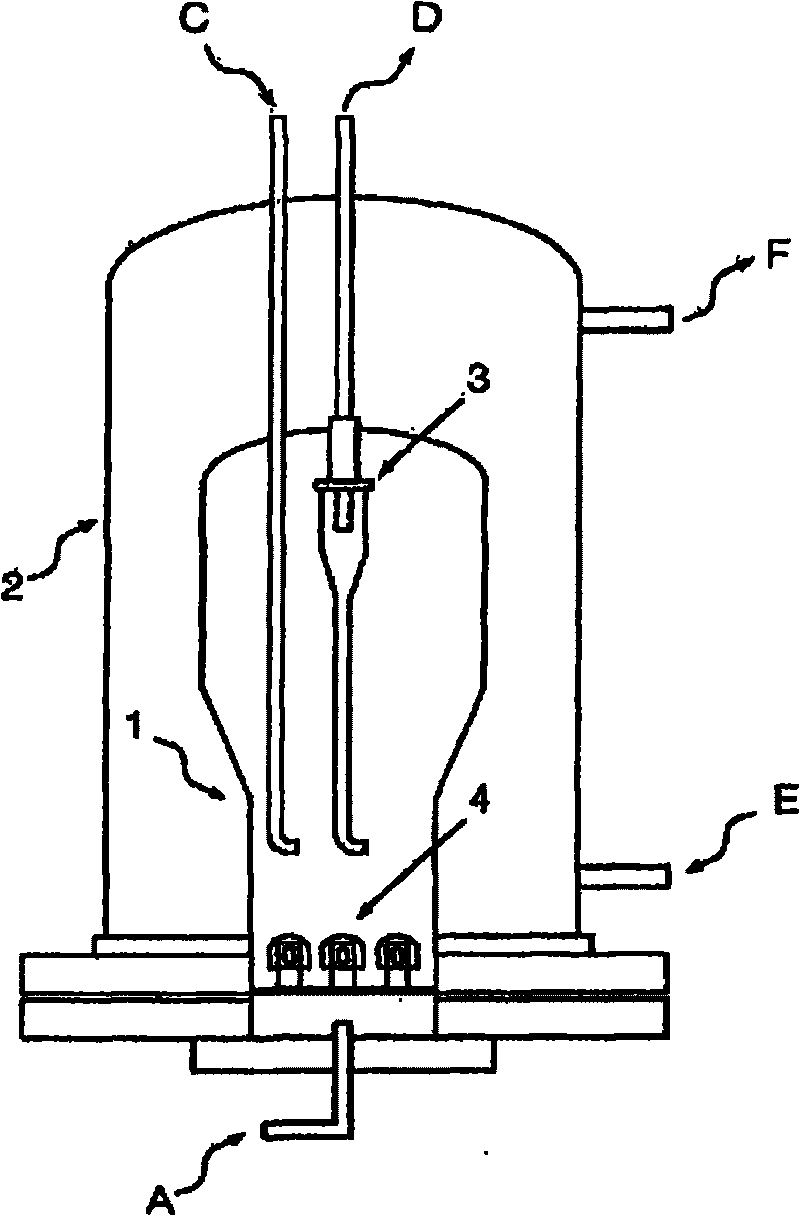

[0038] In the present invention, fine particle tungsten powder having a particle diameter of 0.1 to 100 μm is used as tungsten. Tungsten has a very large specific gravity of 19.25g / cm 3 , on the contrary, the tap density of powdered tungsten is low, which is 0.2 ~ 10g / cm 3 Therefore, by spraying gas above a certain pressure from the lower part of the reactor through multiple nozzles, the tungsten powder can float in the reaction space, thereby turning the reactor into a fluidized reaction system. Here, the tap density refers to the density when tungsten powder is injected into the reactor from the end of the tungsten supply pipe (C). After drying the 0.1-100μm tungsten powder, feed it into the reactor through the tungsten supply pipe (C), and select nitrogen (N 2 ), helium (He) and argon (Ar) as the initial fluidization gas. The inert gas introduced needs to have a slightly higher pressure at the beginning, and after the fluidization starts, the pressure drops sharply. Even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com