Preparation method of crucible with tungsten coating

A crucible and coating technology, which is applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., to reduce the risk of heterogeneous nucleation, improve service life, and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

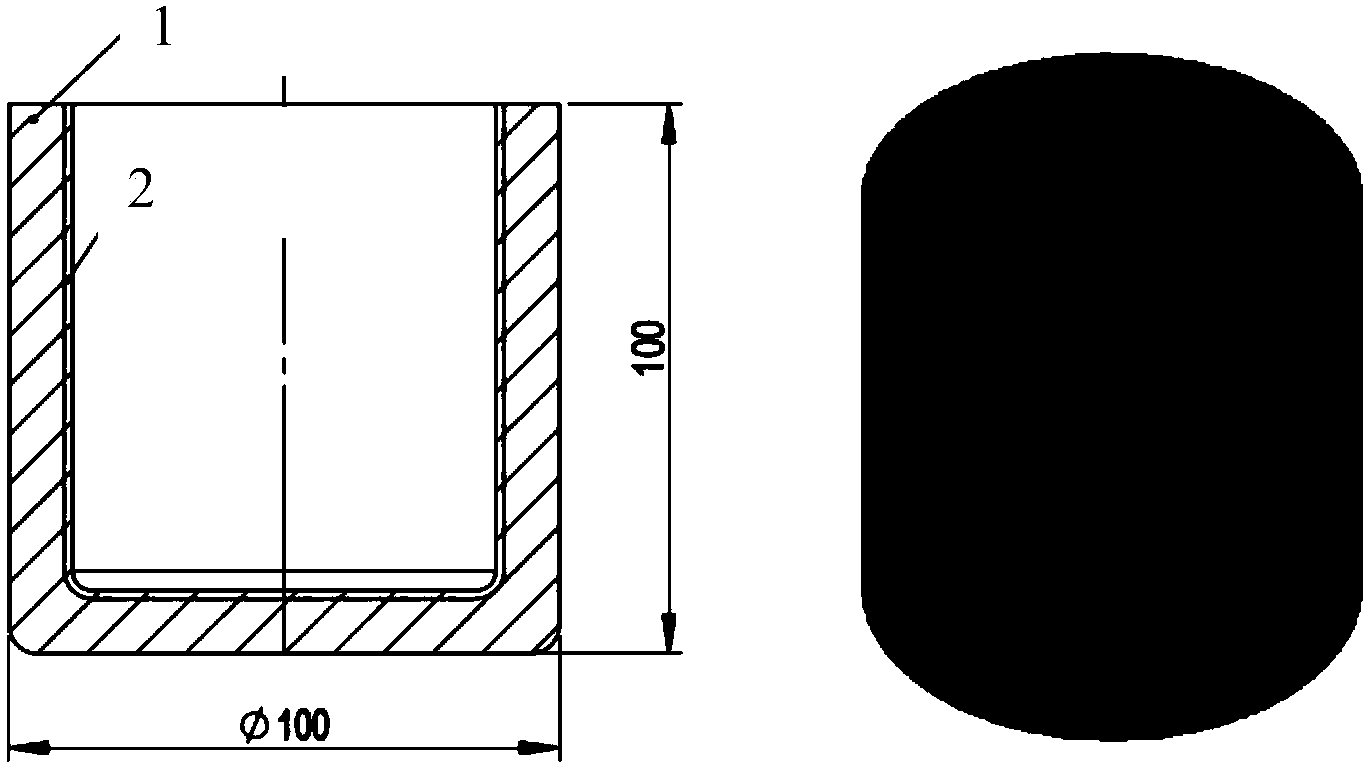

[0043] This example is used to prepare the tungsten substrate crucible coated with pure tungsten coating, see figure 1 , the implementation steps are as follows:

[0044] (1) According to the required size, the pure tungsten crucible of the required cylindrical shape is processed and prepared by powder sintering method. The size of the crucible is Φ100mm in outer diameter and 100mm in height.

[0045] (2) Sandblast the surface of the prepared tungsten crucible with 100-mesh alumina for more than ten minutes, clean it with ultra-pure water ultrasonic waves, and then use sodium hydroxide (5mol / L) and deionized water to make lye to the crucible Surface wash, then dry.

[0046] (3) Put the processed substrate into the chemical vapor deposition reaction chamber, and evacuate to 1.0×10 -1 At about Pa, inject nitrogen gas to replenish the pressure of the deposition chamber to normal pressure, repeat three times, then inject hydrogen gas, and raise the temperature under a hydrogen p...

Embodiment 2

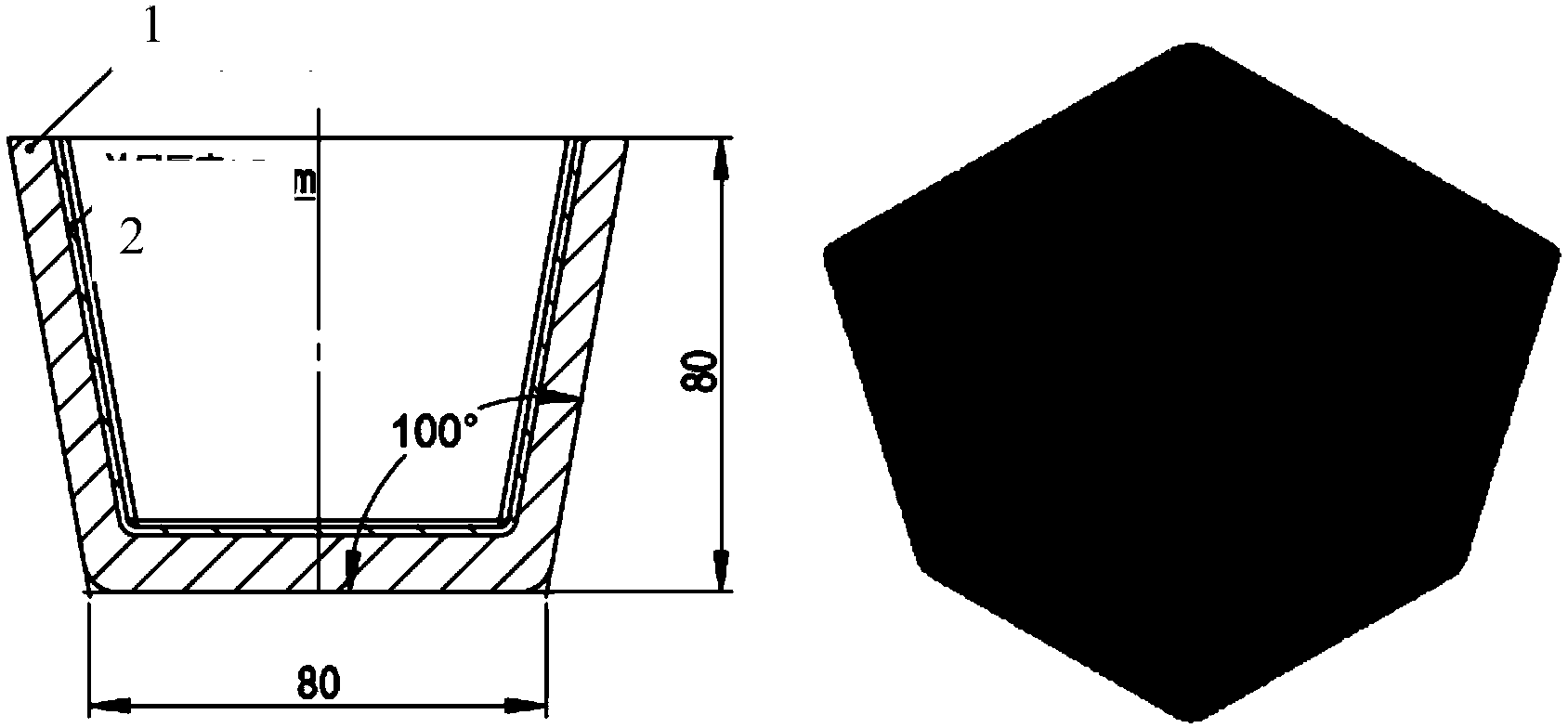

[0051] This example is used to prepare the molybdenum alloy substrate crucible coated with pure tungsten coating, see figure 2 , the implementation steps are as follows:

[0052] (1) The TZM molybdenum alloy crucible is prepared by powder metallurgy process, the bottom size of the crucible is 80×80mm, and the height is 80mm.

[0053] (2) Grind the inner wall surface of the processed crucible base material with about 1000# sandpaper, clean it with ultra-pure water ultrasonic waves, and then use sodium hydroxide (1mol / L) and deionized water to make lye to surface the crucible Wash then tumble dry.

[0054] (3) Put the above-mentioned cleaned and dried crucible substrate into the CVD reaction chamber, and evacuate to 1.0×10 -1 At about Pa, inject nitrogen gas to replenish the pressure of the deposition chamber to normal pressure, repeat three times, then inject hydrogen gas, and raise the temperature under a hydrogen protective atmosphere. After the temperature of the inner w...

Embodiment 3

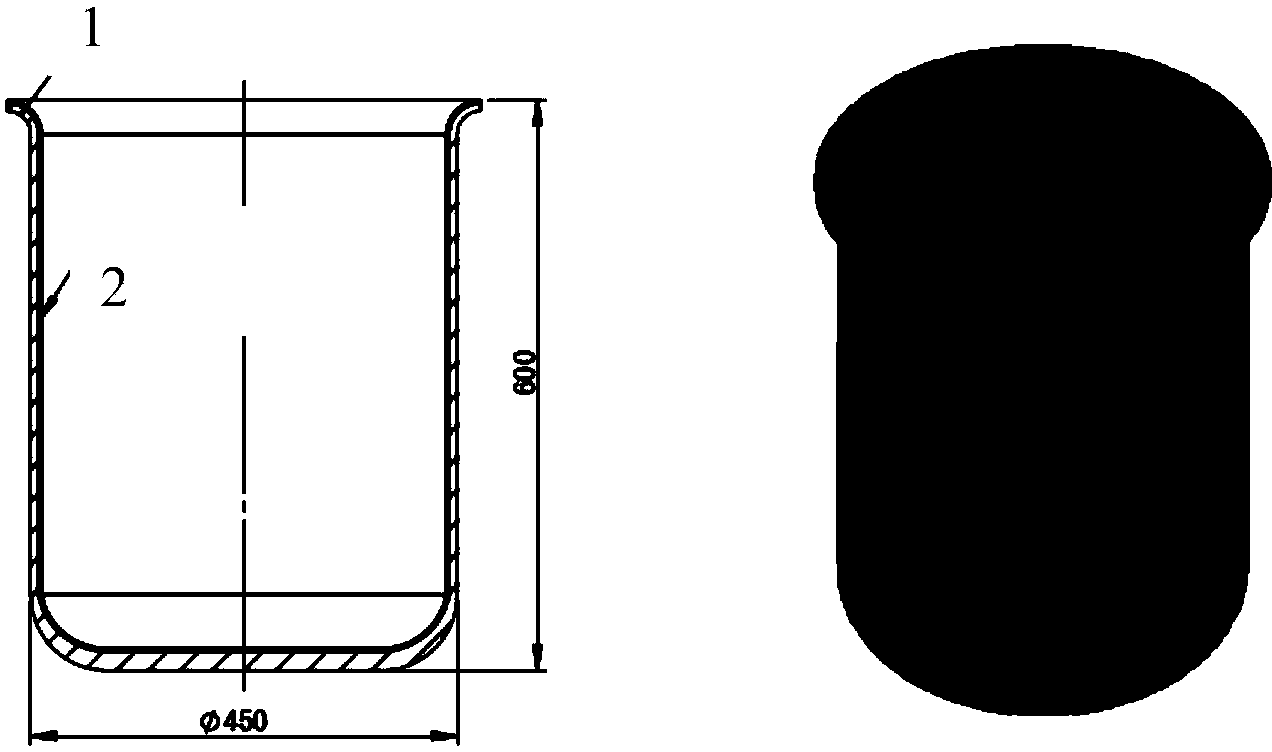

[0059] This example is used to prepare a processed molybdenum crucible coated with a pure tungsten coating, see image 3 , the implementation steps are as follows:

[0060] (1) The rolled molybdenum plate is processed into a molybdenum crucible base material with a diameter of Φ450mm, a height of 600mm and a wall thickness of 1mm by hot spinning process.

[0061] (2) Grind the inner wall surface of the processed molybdenum crucible base material with about 3000# sandpaper, use ultrapure water to clean it ultrasonically, and then use sodium hydroxide (1mol / L) and deionized water to make lye to clean the crucible Surface wash, then tumble dry.

[0062] (3) Put the above-mentioned cleaned and dried molybdenum crucible into the chemical vapor deposition reaction chamber, and evacuate to 1.0×10 -1 At about Pa, inject nitrogen gas to replenish the pressure of the deposition chamber to normal pressure, repeat three times, then inject hydrogen gas, and raise the temperature under a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com