Adsorption tower for preparing high purity tungsten hexafluoride and using method thereof

A technology of tungsten hexafluoride and adsorption tower, which is applied in the field of tungsten hexafluoride preparation, can solve the problems of adsorption tower clogging, clogging channels, affecting product yield, etc., achieve stable working parameters, increase operating flexibility, and good preheating effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

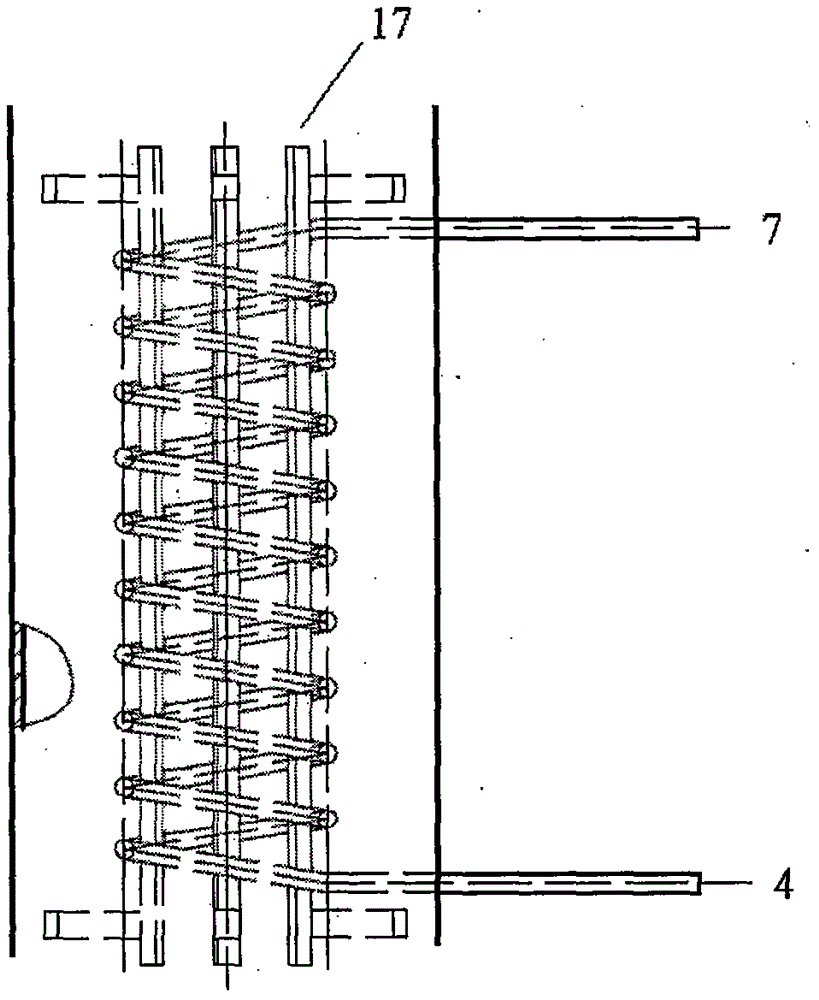

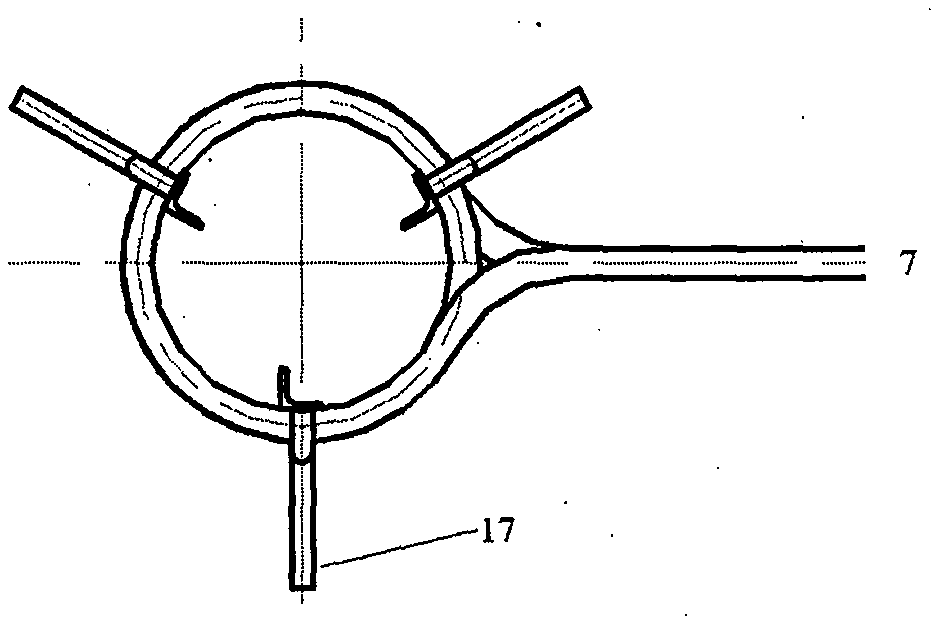

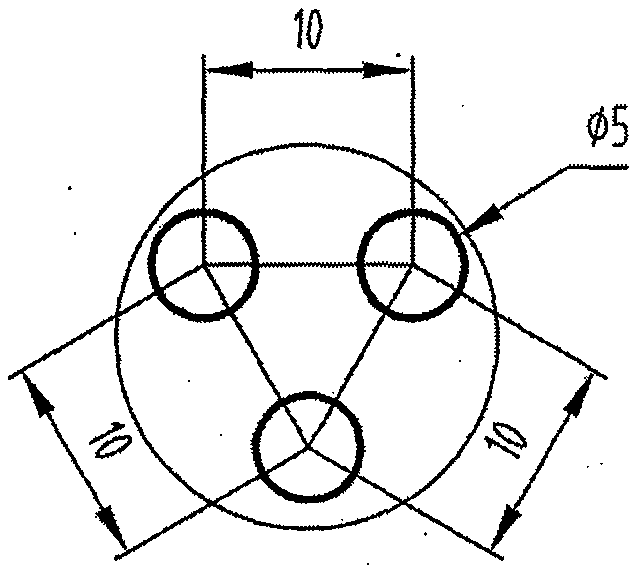

[0034] The diameter of the tower is 300mm, the height of the first tower is 600mm, and the height of the second tower is 1000mm. The outer wall of the tower is equipped with a PID automatic temperature control electric heating jacket. The apertures of the sieve plates 12 and 15 are 5mm, and the center distance of the holes is 10mm.

[0035] Taking purified tungsten hexafluoride as an example, before starting the adsorption tower, add dry and clean nickel wire into the primary tower body 14, and add 6 kg of granular porous particle adsorbent into the secondary tower body 6. High-purity nitrogen gas was introduced, and the adsorbent in the secondary tower body 6 was heated to 400° C. for activation. When the HF content in the purge gas was measured to be less than 5ppmv, the activation was completed. The normal adsorption temperature of the primary and secondary towers is controlled at 40-50 °C, the nitrogen blowing is turned off, and the gas outlet 8 is cut to the product colle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com