Fluidized bed synthesizing device for tungsten hexafluoride

A synthesis device, tungsten hexafluoride technology, applied in the direction of tungsten halide, etc., can solve the problems of unfavorable collection of gas and liquid at the same time, frequent parking, low efficiency, etc., and achieve the effects of avoiding by-products, improving utilization rate, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to easily understand the technical means, creative features, goals and effects of the present invention, the present invention will be further described below in conjunction with specific illustrations.

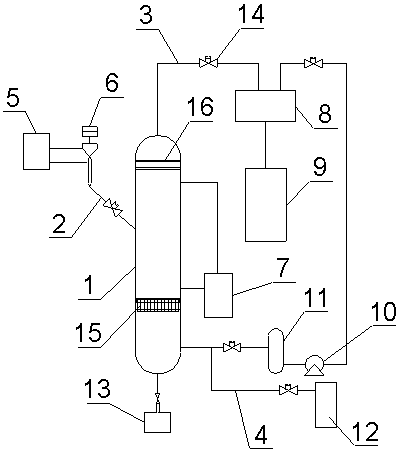

[0022] Such as figure 1 As shown, a fluidized bed synthesis device for tungsten hexafluoride includes a fluidized bed reactor 1, a feed pipe 2, a feed pipe 3, an air inlet pipe 4, a nitrogen purge tank 5, a quantitative hopper 6, a heating 7, condenser 8, collection tank 9, air compressor 10, buffer tank 11 and fluorine-containing mixed gas tank 12, fluidized bed reactor 1 is provided with feed inlet, air inlet and exhaust port, fluidized The bed reactor 1 is provided with a feeding tray 15, and the feeding port and the air inlet are respectively located above and below the feeding tray 15, and the feeding pipe 2 connects the feeding port with the quantitative hopper 6, and the feeding pipe 3 The exhaust port is connected to the condenser 8, and the air inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com