Treating fluid for preparing zirconium-containing coloring passive film on surface of aluminum alloy and treating method thereof

A technology of aluminum alloy surface and treatment method, which is applied in the direction of metal material coating process, etc., can solve the problems of corrosion resistance gap, no color, limit the application of passivation film, etc., and achieve high oxidation resistance, good quality and protective performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

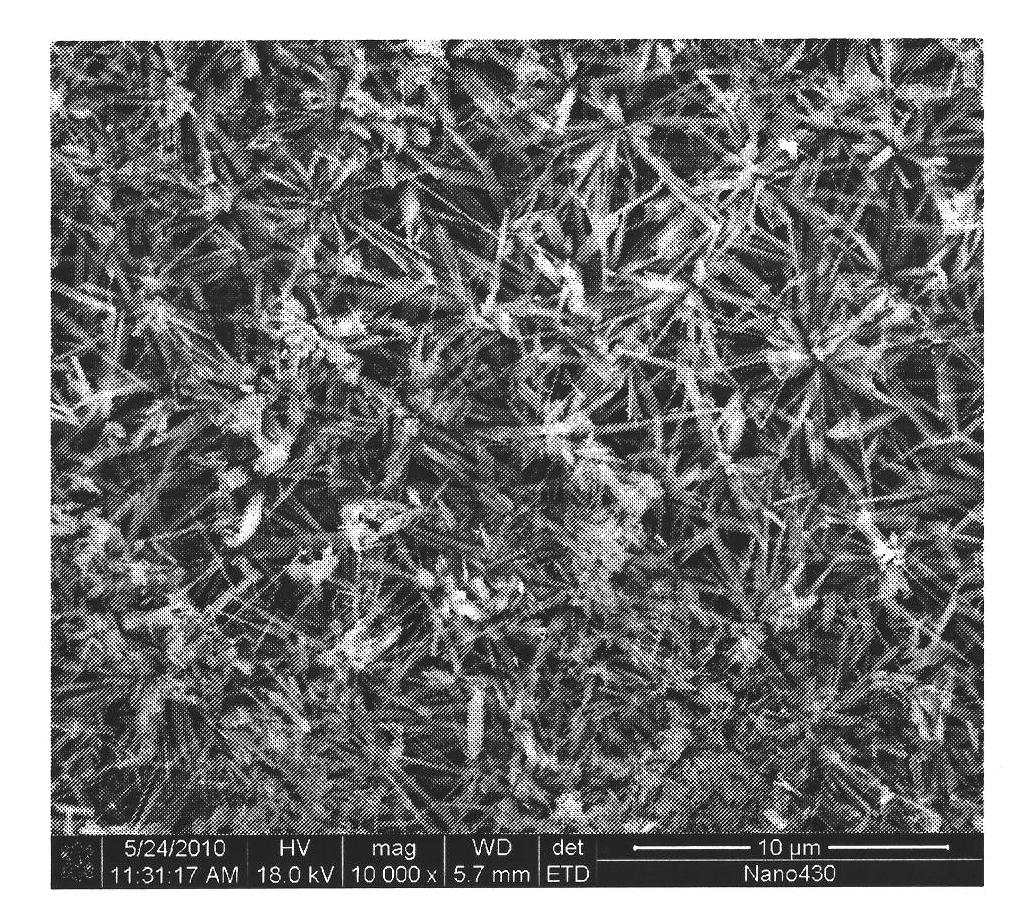

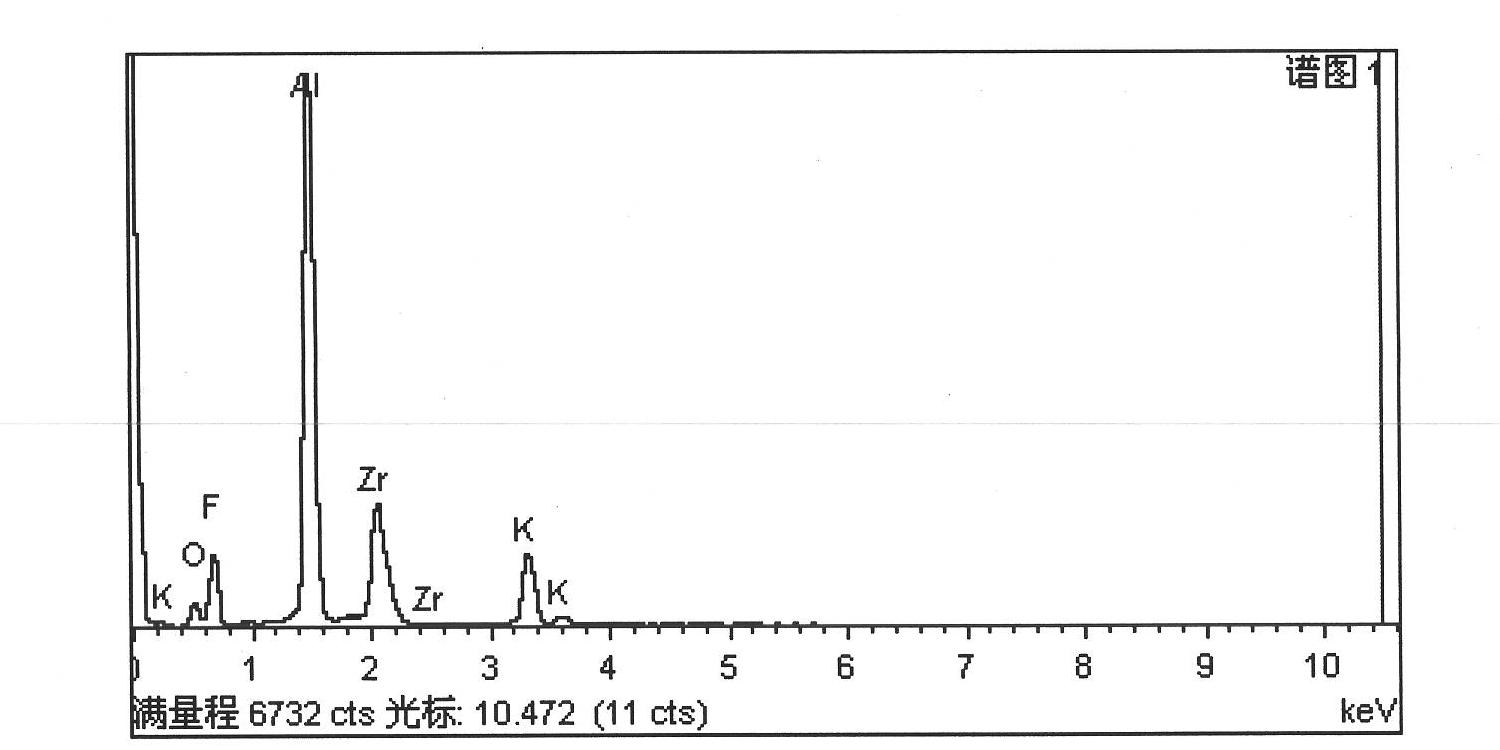

[0049] Example 1: Zirconium passivation treatment on the surface of 6063 aluminum alloy profiles

[0050] The zirconium chemical passivation treatment method on the surface of aluminum alloy comprises the following steps:

[0051] (1) Pretreatment: (a) Cut 3×3cm from 6063 large-size aluminum alloy profiles 2 The samples were drilled and polished with SiC water sandpaper to remove the surface dirt of the aluminum alloy, and the surface dirt was cleaned with tap water and used directly or dried for later use, and the aluminum sheet sample was fixed at the punched place with an aluminum wire; (b ) Prepare a NaOH solution with a concentration of 3 wt%, and immerse the aluminum sheet sample in the solution for etching. This step can be processed at room temperature for 5 minutes, and can also be processed for 2 minutes under ultrasonic vibration conditions, and then rinsed with deionized water. Immerse in nitric acid solution for 1 minute, then rinse with deionized water, use dir...

Embodiment 2

[0055] Example 2: 6063 aluminum alloy profile high concentration zirconium passivation treatment

[0056] The zirconium chemical passivation treatment method on the surface of aluminum alloy comprises the following steps:

[0057] (1) Pretreatment: Pretreatment: (a) Cut 3×3cm from 6063 large-size aluminum alloy profiles 2 The samples were drilled and polished with SiC water sandpaper to remove the surface dirt of the aluminum alloy, and the surface dirt was cleaned with tap water and used directly or dried for later use, and the aluminum sheet sample was fixed at the punched place with an aluminum wire; (b ) preparing a NaOH solution with a concentration of 3wt%, immersing the aluminum sheet sample in the solution, treating it at 30° C. for 3 minutes, and then rinsing it with deionized water; (c) immersing the processed sample in step (b) for 10 % (percentage by weight) dipped in dilute nitric acid solution for 1 minute, then rinsed with deionized water, directly used or drie...

Embodiment 3

[0061] Example 3: Zirconium passivation treatment on the surface of 6063 aluminum alloy profiles after simple degreasing

[0062] The zirconium chemical passivation treatment method on the surface of aluminum alloy comprises the following steps:

[0063] (1) Pretreatment: cut 3×3cm from 6063 large-size aluminum alloy profiles 2 Then use SiC water sandpaper to remove the dirt on the surface of the aluminum alloy, clean the surface dirt with tap water and use it directly or dry it for later use, and fix the aluminum sheet sample at the punched place with an aluminum wire.

[0064] (2) Configuration of zirconium chemical passivation treatment solution: configure 100ml of zirconium passivation treatment solution, wherein the concentrations of various components in the treatment solution are as follows: fluorozirconic acid 20g / l, potassium fluoride 0.5g / l, potassium fluorozirconate 0.5 g / l, polyvinyl alcohol 0.8g / l, phosphoric acid to adjust the pH value to 4.0.

[0065] (3) Zirc...

PUM

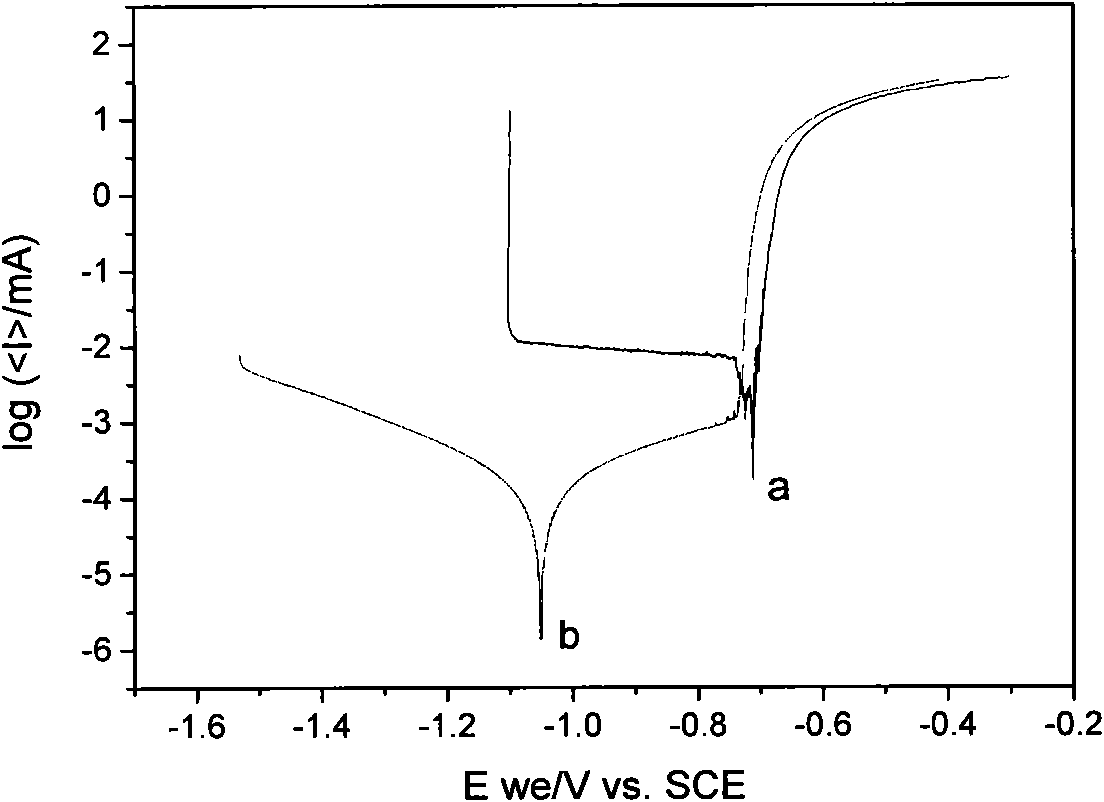

| Property | Measurement | Unit |

|---|---|---|

| corrosion current | aaaaa | aaaaa |

| corrosion current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com