Magnesium base degradable implant material and preparation method thereof

A technology for implants and substrates, applied in prostheses, coatings, medical science, etc., can solve the problems of lack of human implant materials, and achieve the effect of high microhardness and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of magnesium-based degradable implant material (1#ZK60):

[0033] 1) The base material is ZK60, cut into 8×10×12mm 3 Cuboid small pieces are polished on sandpaper of different thicknesses, the last sandpaper is 1000#, and then ultrasonically cleaned in acetone and dried;

[0034] 2) Weigh sodium silicate, potassium hydroxide, potassium fluoride, soluble phosphate, triethanolamine and dissolve them in pure water to prepare an electrolyte. The main components of the electrolyte are: Na 2 SiO 3 15g / L, KOH 5g / L, KF 3g / L, (NaPO 3 ) 6 5g / L, the sample is connected to the positive pole of the power supply, suspended in the electrolyte, and the electrolytic cell is connected to the negative pole of the power supply for micro-arc oxidation treatment under constant current conditions. The constant current condition is: current density 9.0A / dm 2 , Oxidation time 30min, frequency 600Hz, duty cycle 10%;

[0035] 3) Wash the sample obtained in step 2) with deionize...

Embodiment 2

[0037] Preparation of magnesium-based degradable implant material (2#ZK60):

[0038] 1) The base material is ZK60, cut into 8×10×12mm 3 Cuboid small pieces are polished on sandpaper of different thicknesses, the last sandpaper is 1000#, and then ultrasonically cleaned in acetone and dried;

[0039] 2) Weigh sodium silicate, potassium hydroxide, potassium fluoride, soluble phosphate, triethanolamine and dissolve them in pure water to prepare an electrolyte. The main components of the electrolyte are: Na 2 SiO 3 15g / L, KOH 5g / L, KF 3g / L, (NaPO 3 ) 6 5g / L, the sample is connected to the positive pole of the power supply, suspended in the electrolyte, and the electrolytic cell is connected to the negative pole of the power supply for micro-arc oxidation treatment under constant current conditions. The constant current condition is: current density 3.5A / dm 2, Oxidation time 30min, frequency 600Hz, duty cycle 10%;

[0040] 3) Wash the sample obtained in step 2) with deionized...

Embodiment 3

[0042] Preparation of magnesium-based degradable implant material (1#ZK61):

[0043] 1) The base material is ZK61, cut into 8×10×12mm 3 Cuboid small pieces are polished on sandpaper of different thicknesses, the last sandpaper is 1000#, and then ultrasonically cleaned in acetone and dried;

[0044] 2) Weigh sodium silicate, potassium hydroxide, potassium fluoride, soluble phosphate, triethanolamine and dissolve them in pure water to prepare an electrolyte. The main components of the electrolyte are: Na 2 SiO 3 15g / L, KOH 5g / L, KF 3g / L, (NaPO 3 ) 6 5g / L, the sample is connected to the positive pole of the power supply, suspended in the electrolyte, and the electrolytic cell is connected to the negative pole of the power supply for micro-arc oxidation treatment under constant current conditions. The constant current condition is: current density 3.5A / dm 2 , Oxidation time 30min, frequency 600Hz, duty cycle 10%;

[0045] 3) Wash the sample obtained in step 2) with deionize...

PUM

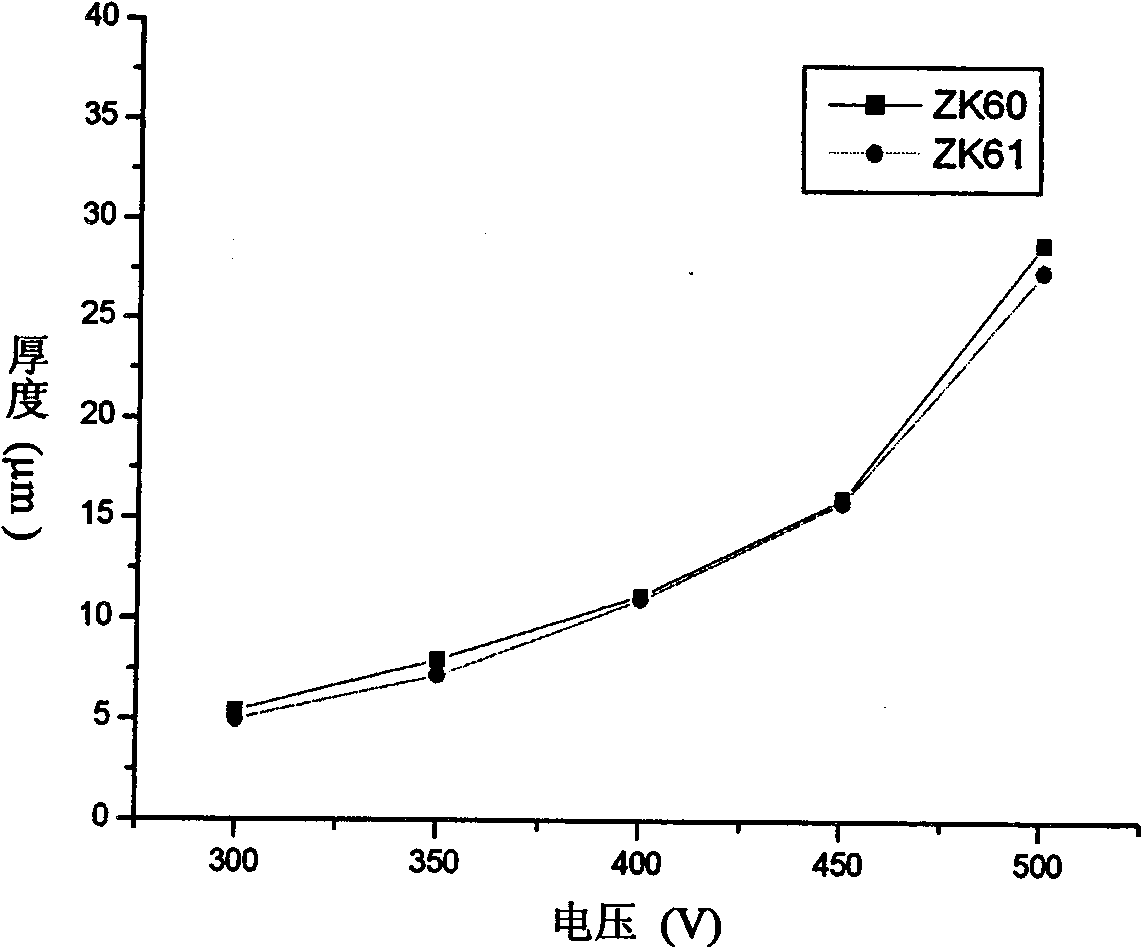

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com