Method and device for extracting bitten lithium chloride

A technology of salt-halide lithium chloride and an extraction method is applied in the field of extraction and device of salt-halide lithium chloride, and can solve the problems of inability to increase the concentration ratio, consumption of large reagents, and low efficiency of drying salt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

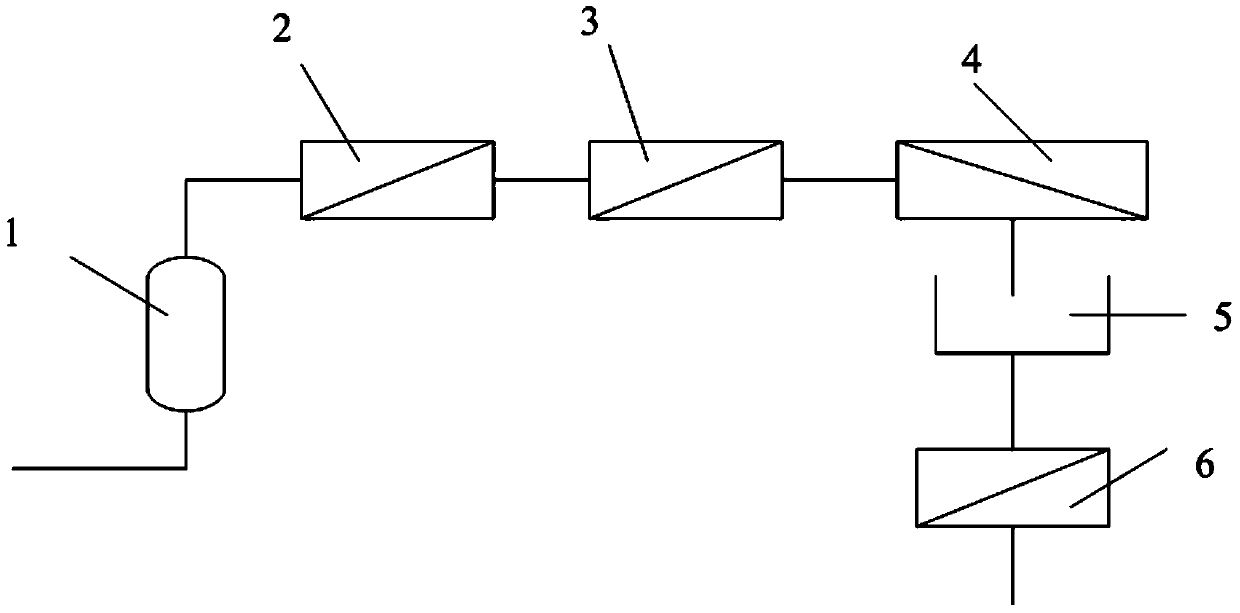

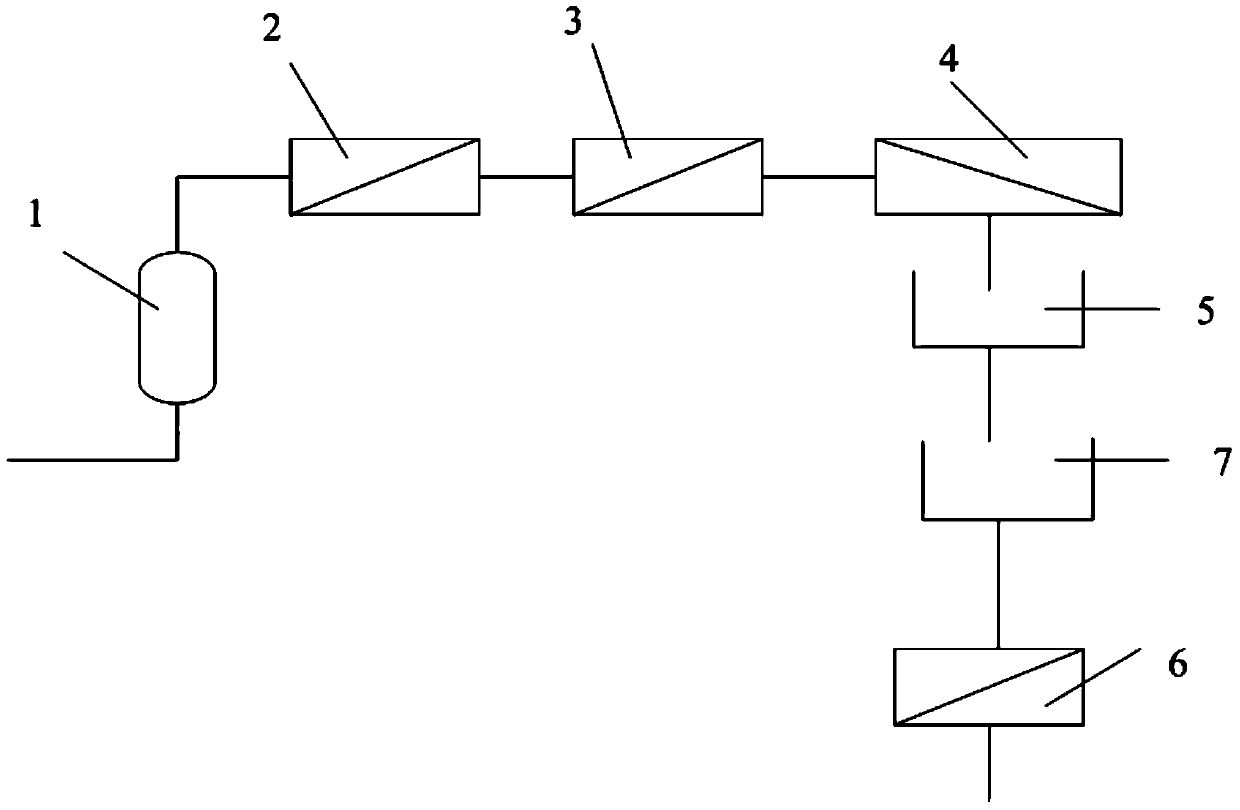

Image

Examples

Embodiment 1

[0040] Effect of salt lake old brine on Li by aluminum salt adsorbent + After adsorption, then supply deionized water for elution to obtain a desorption solution, when the Mg in the desorption solution is detected 2+ When the content is about 2 g / L, the desorption liquid is sent to the coarse filter to remove the adsorbent particles and sediment, and the permeate enters the primary nanofiltration membrane element for filtration, and the Ca in the desorption liquid 2+ The content is 46.38mg / L, Mg 2+ The content is 2g / L, Li + The content is 412mg / L. After the desorption liquid passes through the primary nanofiltration membrane element, the Ca in the permeate 2+ , Mg 2+ and Li + The content is 25mg / L, 350 mg / L and 556 mg / L. The operating temperature of the primary nanofiltration membrane system is 45°C, the pressure is 1.5 MPa, and the concentration factor is 4 times. The primary nanofiltration membrane permeate enters the secondary nanofiltration membrane element, and the...

Embodiment 2

[0043] Salt Lake Old Brine by Adsorbent + After adsorption, then supply deionized water for elution to obtain a desorption solution, when the Mg in the desorption solution is detected 2+ When the content is about 0.5 g / L, the desorption liquid is sent to the coarse filter to remove the adsorbent particles and sediment, and the permeate enters the primary nanofiltration membrane element for filtration, and the Ca in the desorption liquid 2+ The content is 43.74mg / L, Mg 2+ The content is 0.5 g / L, Li + The content is 432mg / L. After the desorption liquid passes through the primary nanofiltration membrane element, the Ca in the permeate 2+ , Mg 2+ and Li + The content is 22mg / L, 280 mg / L and 389 mg / L. The operating temperature of the primary nanofiltration membrane system is 45°C, the pressure is 1.5 MPa, and the concentration factor is 4 times. The primary nanofiltration membrane permeate enters the secondary nanofiltration membrane element, and the Ca in the secondary nano...

Embodiment 3

[0046] Effect of salt lake old brine on Li by aluminum salt adsorbent + After adsorption, then supply deionized water for elution to obtain a desorption solution, when the Mg in the desorption solution is detected 2+ When the content is about 3 g / L, the desorption liquid is sent to the coarse filter to remove the adsorbent particles and sediment, and the permeate enters the primary nanofiltration membrane element for filtration, and the Ca in the desorption liquid 2+ The content is 49.55mg / L, Mg 2+ The content is 3g / L, Li + The content is 409mg / L. After the desorption liquid passes through the primary nanofiltration membrane element, the Ca in the permeate 2+ , Mg 2+ and Li + The content is 27mg / L, 380 mg / L and 565 mg / L. The operating temperature of the primary nanofiltration membrane system is 45°C, the pressure is 1.5 MPa, and the concentration factor is 4 times. The primary nanofiltration membrane permeate enters the secondary nanofiltration membrane element, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com