Preparation method of spherical CsPbX3@SiO2 quantum dot with high stability and water solubility

A high-stability, water-soluble technology, applied in chemical instruments and methods, nanotechnology, nano-optics, etc., can solve the problems of poor stability and water solubility, limiting the application of luminescent materials, etc., and achieve the effect of improving stability and water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0017] (1) Weigh 0.08g of cesium carbonate and add it to a mixed solution containing 3mL of octadecene and 0.25mL of oleic acid, and heat to 150°C under a nitrogen atmosphere until the cesium carbonate is completely dissolved;

[0018] (2) Accurately weigh 68.9mg of PbBr 2 Add it into a mixed solution containing 5mL octadecene, 0.5mL oleic acid and 5mL oleylamine, heat to 180°C under a nitrogen atmosphere, and the heating rate is 4°C / min, to PbBr 2 completely dissolved;

[0019] (3) Measure 0.4mL of the cesium oleate solution in step (1) and quickly add it dropwise to the solution in step (2), react for 6s, quickly cool to room temperature in ice bath, and centrifuge, wash, and vacuum dry the product to obtain CbBr 3 quantum dots;

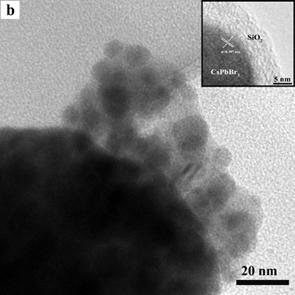

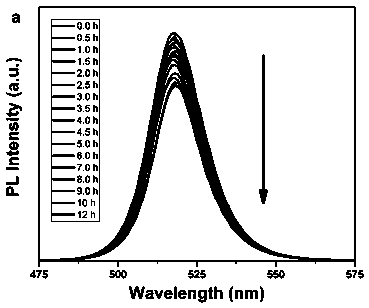

[0020] (4) Weigh 16 mg of CsPbbr obtained in step (3) 3 The quantum dots were evenly dispersed in 20 mL of toluene solution, 100 μL of TMOS and 70 μL of deionized water were added to it, and the reaction was fully reacted for 48 h at room tempe...

Embodiment example 2

[0022] The difference between this example and Example 1 is that 26.1 mg of PbCl is added in step (2) 2 and 34.5mg of PbBr 2 , all the other conditions are the same as in Example 1.

Embodiment example 3

[0024] The difference between this example and Example 1 is that 52.3 mg of PbCl is added in step (2) 2 , all the other conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com