Vertical rotor type gas electromagnetic valve

一种燃气电磁阀、转子式的技术,应用在阀细节、阀装置、阀的操作/释放装置等方向,能够解决转子与定子精确定位定子结构加工难度及成本高、未考虑到调节、未考虑到磁路长度等问题,达到有效绕组周长减少、漆包线及导磁材料用量减少、节省材料的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

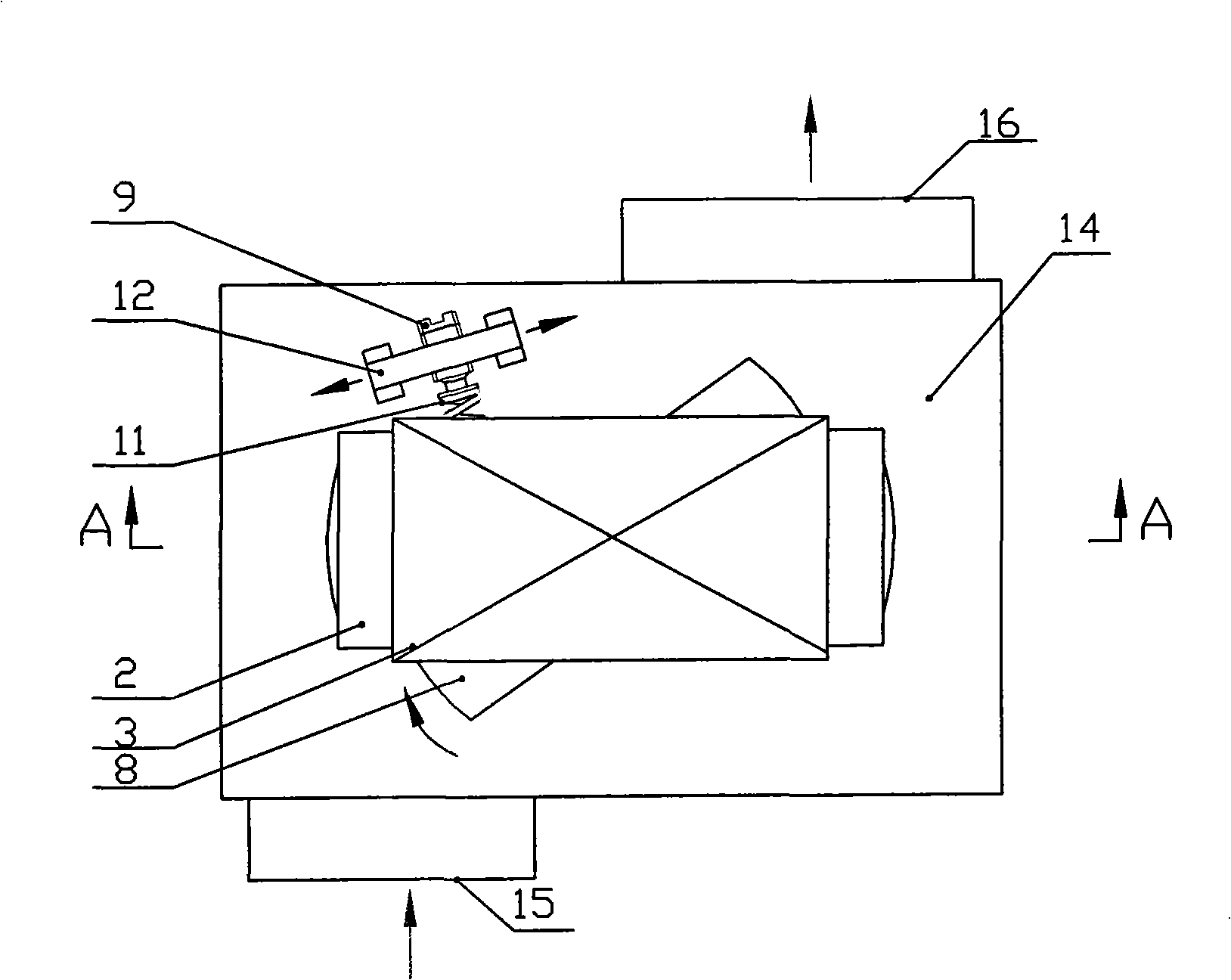

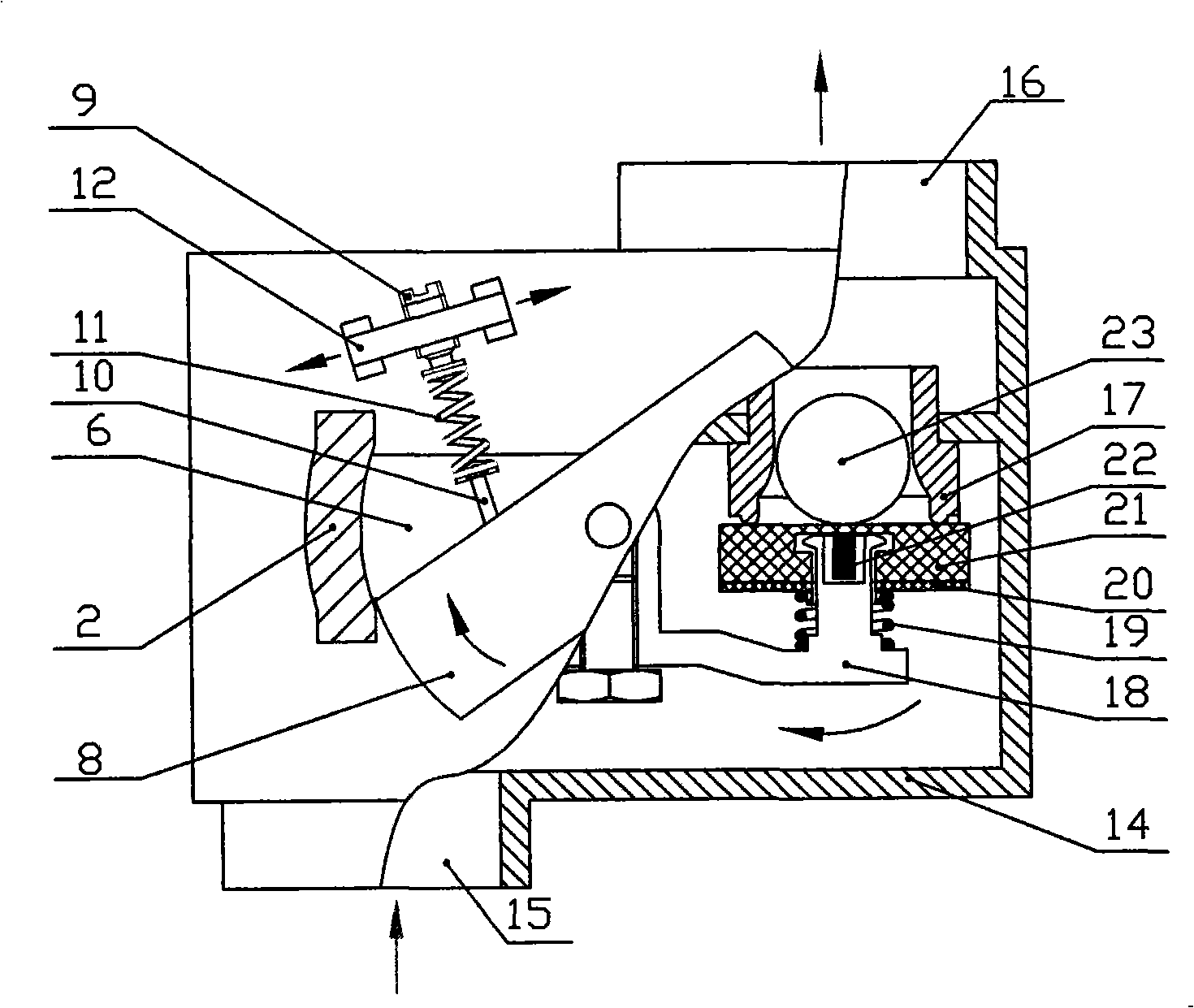

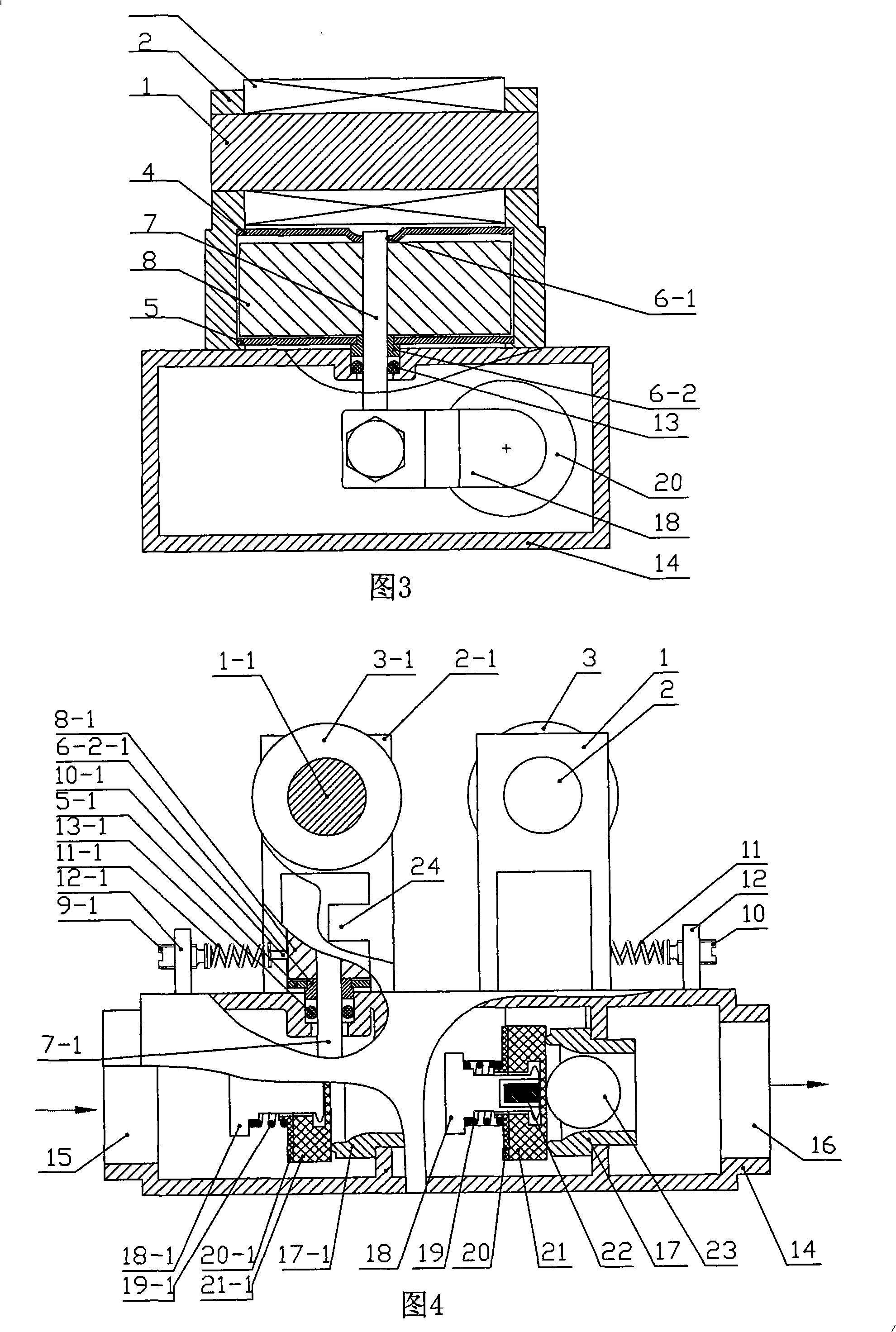

[0025] see figure 1 , figure 2 , Fig. 3 can be seen, a kind of vertical rotor type gas electromagnetic valve is installed on the vertical rotor type electromagnet, valve housing 14, adjustment spring 11, adjustment nail 10, rotor adjustment screw 9, adjustment screw bracket 12, swing arm 18 and The rubber gasket assembly at the outer end of the swing arm 18 is composed, and the valve housing 14 is provided with an air inlet 15 , an air outlet 16 and a valve port 17 . The vertical rotor electromagnet consists of coil winding 3, stator core 1, stator side piece 2, rotor 8, upper rotor fixing piece 4, and lower rotor fixing piece 5. The rotor 8 is long and has front and rear Symmetrical outer arc.

[0026] The rotor shaft 7 of the vertical rotor type electromagnet is located on the center line of the stator core 1, the upper and lower rotor fixing pieces 4 and 5 are at an angle of 90° to the rotor shaft, and the upper rotor fixing piece 4 is located on the upper side of the ro...

Embodiment 2

[0034] Referring to Fig. 4, the present embodiment is a double-enclosed gas flow regulating valve composed of two vertical rotor type gas solenoid valves, one of which is used as a gas regulating valve, which is the same as in Embodiment 1. And the other is used for gas opening and closing alone, its structure is the same as the main body structure described in embodiment 1, the difference is that it is provided with boss 24 on the inner arc surface of a stator side piece 2-1, and cancels A permanent magnet 22 and a magnetic permeability adjustment block 23 are provided. That is, in Fig. 4, the gas control valve is located on the right side, and the gas switching valve is located on the left side, which together form a gas control valve with double sealing effect. Stator iron core 1-1, stator side piece 2-1, coil winding 3-1, upper rotor fixing piece 4-1, lower rotor fixing piece 5-1, bearing boss 6-2- of the gas switching valve in Fig. 4 1. Rotor shaft 7-1, rotor 8-1, rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com