Washing machine bionic hand rub frequency conversion deceleration clutch

A deceleration clutch and bionic hand technology, which is applied in other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of complicated installation and connection, not much improvement in motor efficiency, and many connecting parts of the main part, so as to achieve flexible and smooth operation , good insulation and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

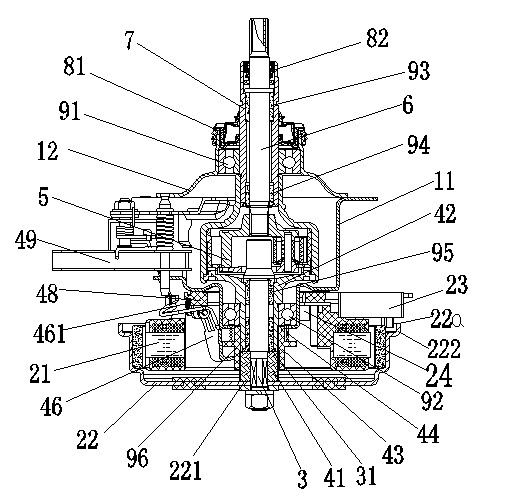

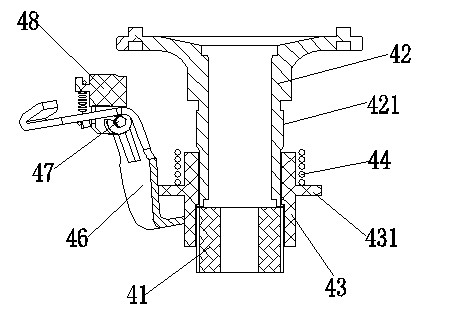

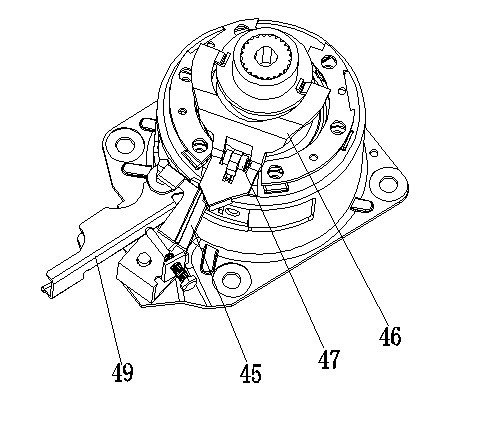

[0017] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] Figure 1 to Figure 4 Shown is the structural representation of the present invention.

[0019] The reference signs are: lower housing 11, upper housing 12, plastic-encapsulated brushless DC motor stator 21, outer rotor 22 of DC brushless motor, upper end edge 22a, via hole boss 221, round shoulder 222, Hall Component feedback assembly 23, stator fastening screw 24, input shaft 3, lower end boss side 31, bushing 41, clutch shaft 42, outer peripheral bearing boss 421, clutch slider 43, ring boss 431, clutch spring 44, Clutch lever 45, clutch pressure plate 46, tension spring 461, rotating mandrel 47, rotating shaft fixed block 48, push rod 49, gear reduction system 5, pulsator shaft 6, dehydration shaft 7, large sealing ring 81, small sealing ring 82, The first support bearing 91 , the second support bearing 92 , the first oil bearing 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com