Method for packaging layered quantum dot LED lamp beads

A technology of LED lamp beads and packaging method, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of difficulty in large-scale industrialization, low light conversion efficiency, complex process, etc., to reduce difficulty and product defect rate, The effect of low phosphor concentration and high excitation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

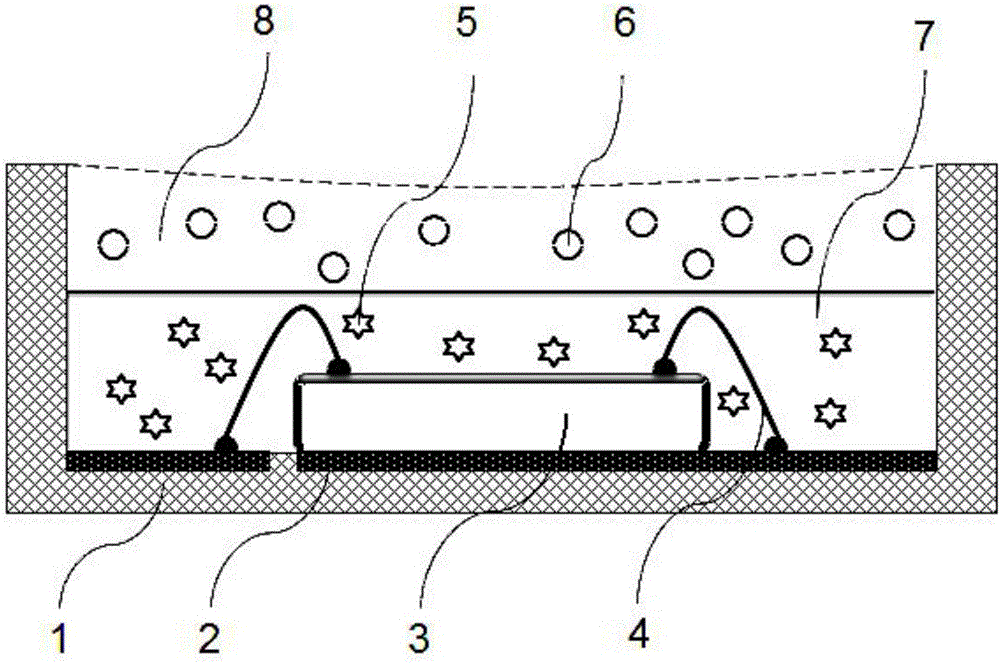

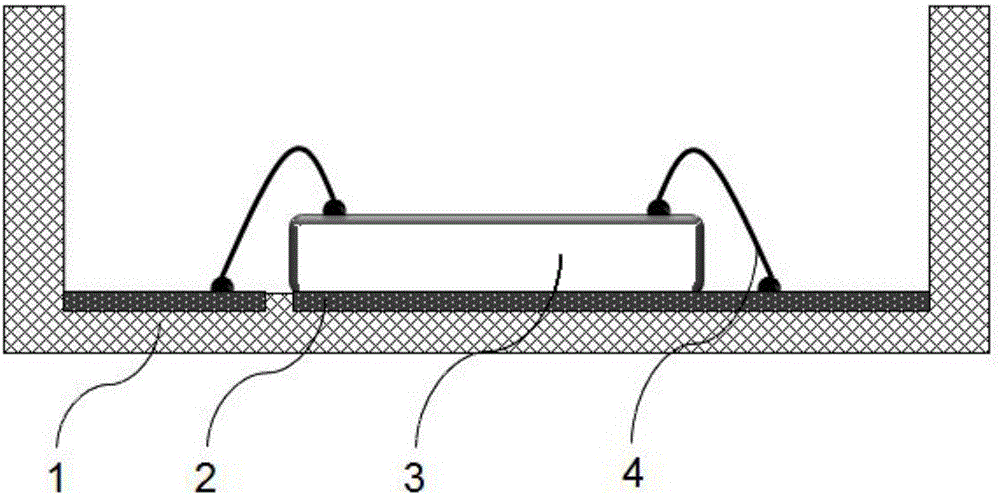

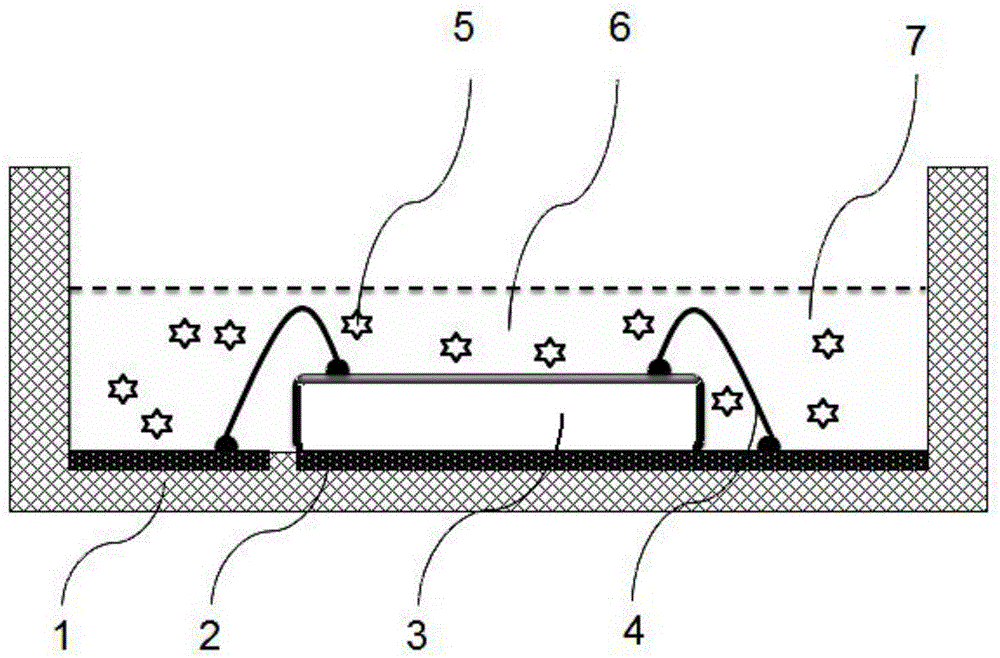

[0035] Embodiment 1: This embodiment discloses a

[0036] 1) Weigh 0.75g of fluoride red phosphor powder with an emission wavelength of 638nm and place it in container A.

[0037] 2) Weigh 2.35g of epoxy-based packaging glue A, pour it into the fluoride red fluorescent powder weighed in step 1), and carry out vacuum defoaming and stirring to obtain fluorescent glue A.

[0038] 3) Take a certain amount of the fluorescent glue A obtained in step 2) and drop it into the LED bracket that has been fixed with a blue light chip (the emission wavelength of the chip is 450nm), and control the volume of the dropped fluorescent glue A to account for 35% of the internal volume of the bracket cup. %.

[0039] 4) Put the LED bracket obtained in step 3) in an oven and bake at 100° C. for 4 hours to cure the luminescent material A fluorescent glue.

[0040] 5) Weigh again 0.08g of PbZrO with an emission wavelength of 544nm 3 , Fe 2 o 3 The green light quantum dot phosphor powder is place...

Embodiment 2

[0045] 1) Weigh 0.13g of CdSe red light quantum dot phosphor powder with an emission wavelength of 635nm, and 0.09g of MgTe and NaCl blue light quantum dot phosphor powder with an emission wavelength of 458nm, and place them in container A.

[0046] 2) Weigh 5.03g of epoxy-based packaging glue A, pour it into the quantum dot fluorescent powder weighed in step 1), and carry out vacuum defoaming and stirring to obtain quantum dot fluorescent glue A.

[0047] 3) Take a certain amount of quantum dot fluorescent glue A obtained in step 2) and drop it into the LED bracket that has been fixed with a UV chip (the chip emits light at a wavelength of 230nm), and control the volume of the dropped fluorescent glue A to occupy the inside of the bracket cup shell 55% of volume.

[0048] 4) Put the LED bracket obtained in step 3) in an oven and bake at 150°C for 1 hour to cure the quantum dot fluorescent glue A.

[0049] 5) Weigh again 0.55g of silicate green fluorescent powder with an emis...

Embodiment 3

[0054] 1) Weigh 0.07g of GaS red light quantum dot phosphor powder with an emission wavelength of 655nm, and place it in container A.

[0055] 2) Weigh 0.72g of silica gel-based packaging glue A, pour it into the GaS red light quantum dot phosphor powder weighed in step 1), and carry out vacuum defoaming and stirring to obtain quantum dot fluorescent glue A.

[0056] 3) Take a certain amount of quantum dot fluorescent glue A obtained in step 2) and drop it into the LED bracket that has been fixed with a blue light chip (the chip emits light at a wavelength of 430nm), and control the volume of the dropped fluorescent glue A to account for the internal volume of the bracket cup shell 5%.

[0057] 4) Put the LED bracket obtained in step 3) in an oven and bake at 50°C for 8 hours to cure the quantum dot fluorescent glue A.

[0058] 5) Weigh again 0.53g of phosphate green dot fluorescent powder with an emission wavelength of 535nm, and place it in container B.

[0059] 6) Weigh 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com