Combined photocatalyst-ClO2 deodorization device and deodorization method adopting same

A photocatalyst and catalyst technology, which is applied in chemical instruments and methods, deodorization, separation methods, etc., can solve the problems of poor odor treatment effect, and achieve the effects of simple structure, reduced deodorization cost, and convenient deodorization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

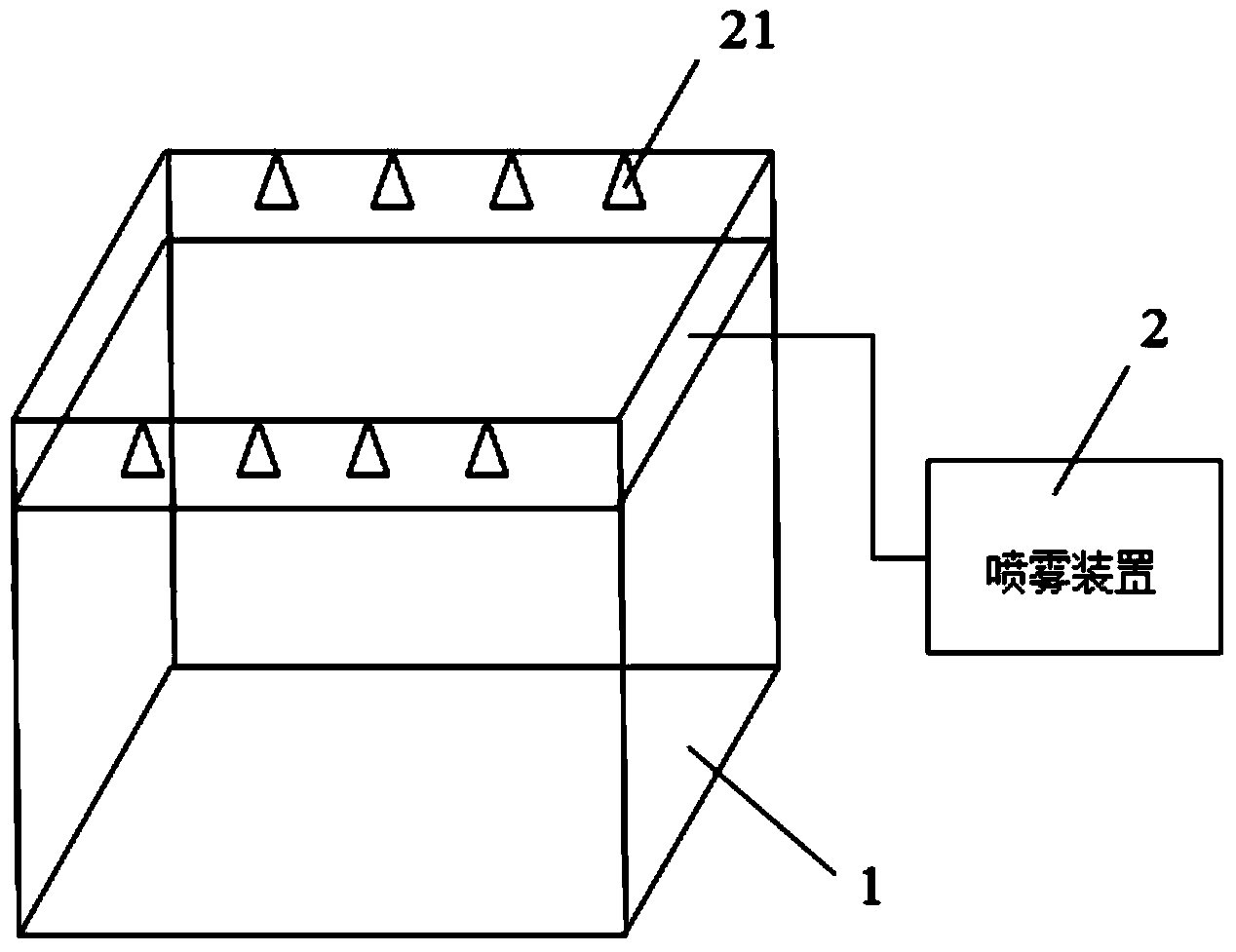

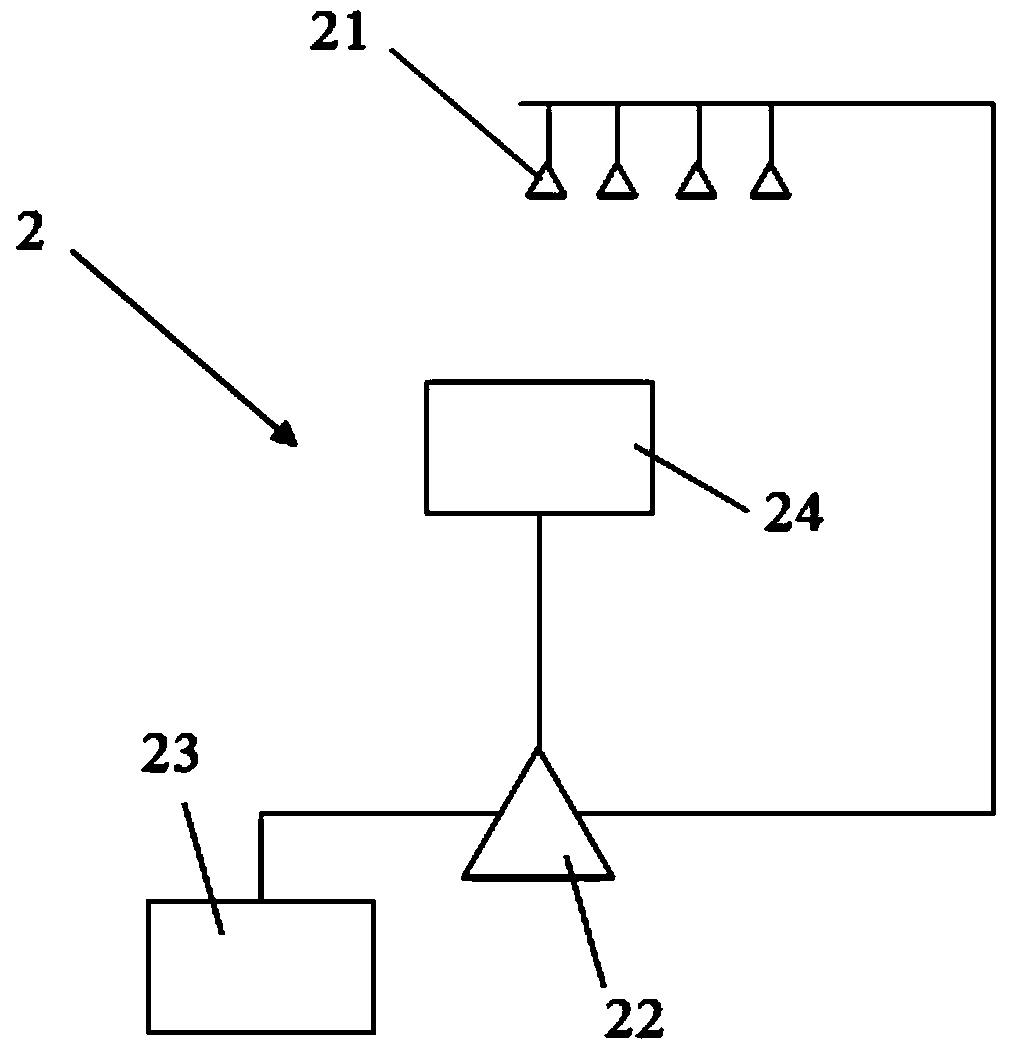

[0039] refer to figure 1 with figure 2 ,Such as figure 1 As shown, the photocatalyst-ClO in this example 2 The combined deodorization device includes an isolation net 1 and a spray device 2, and is used in open environments such as livestock and poultry houses and septic tanks. The isolation net 1 is arranged around the livestock and poultry house and / or septic tank, and the isolation net 1 is loaded with a photocatalyst for degrading the malodorous substance in the air, and the spray device 2 sprays through the spray nozzle 21 arranged on the isolation net 1 ClO 2 disinfectant. Such as figure 2 As shown, in the present embodiment, the spray device 2 includes a spray nozzle 21, a water pump 22, a water tank 23 and a spray electric control box 24, and the spray nozzle 21 is located above the isolation net 1; the spray nozzle 21 passes through the water pump 22 is connected to said water tank 23; Said water tank 23 is used for containing ClO 2 Disinfectant; the spray el...

Embodiment 2

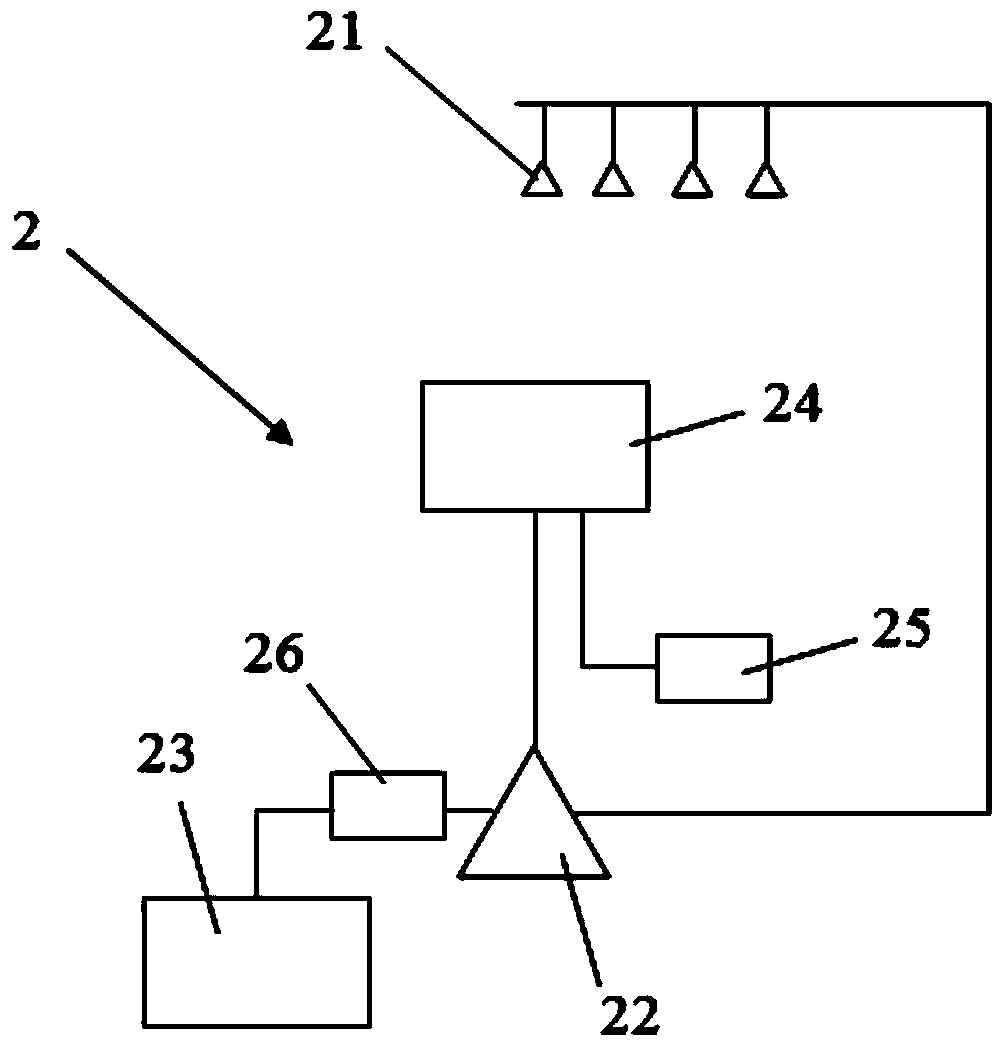

[0043] Such as image 3 As shown, different from Example 1, the photocatalyst-ClO provided by this example 2 The combined deodorizing device also includes a thermo-hygrometer 25 and a filter 26 . The thermo-hygrometer 25 is electrically connected with the spray electric control box 24 for detecting the temperature and humidity in the open environment, and feedbacks the detection result to the spray electric control box 24. Described filter 26 is connected between water pump 23 and tank 24, is used for filtering ClO 2 Disinfectant so that the requirements for fine mist spraying can be met.

[0044] In the present embodiment, on the isolation net 1, be coated with by CT catalyst (20g / m 2 ) and nano-TiO2 catalyst (20g / m 2 ) composed of a combined catalyst, the temperature of the pig house is 22-28°C. Spray and disinfect the piggery every 76 hours, ClO 2 (Chlorine dioxide) concentration is 20ppm, every 10 minutes. After 12 days of testing, the stench of the experimental pig...

Embodiment 3

[0046] Different from Example 2, in the present example, the isolation net 1 is coated with CT catalyst (30g / m 2 ) and nano iron oxide (20g / m 2 ) composed of a combined catalyst, the temperature of the pig house is 22-28°C. Spray and disinfect the piggery every 36 hours, ClO 2 (Chlorine dioxide) concentration is 100ppm, every 60 minutes. After 12 days of testing, the stench of the experimental pig house has been greatly improved. Control group does not use photocatalyst-ClO of the present invention 2 Combined deodorization device, control group NH 3 The average concentration is 13.49mg / m 3 , H 2 The average concentration of S is 9.55mg / m 3 . The average concentration of NH3 in the experimental group was 3.04mg / m 3 , H 2 The average concentration of S is 4.38mg / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com