Microwave-excited ultraviolet sterilizing method, equipment and use

A sterilization equipment, ultraviolet technology, applied in discharge lamps, illumination water/sewage treatment, electrical components, etc., can solve the problems of increasing the diameter of the lamp tube, affecting ultraviolet rays, unsafe, etc., achieving easy moving position, good deodorization effect, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

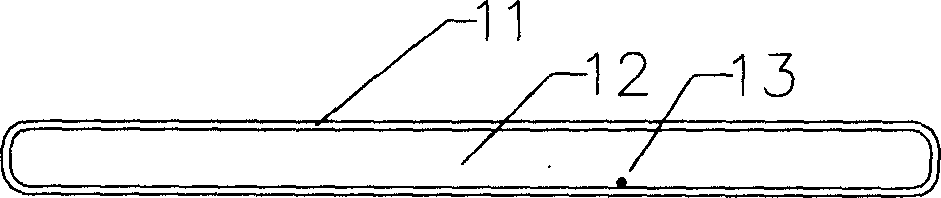

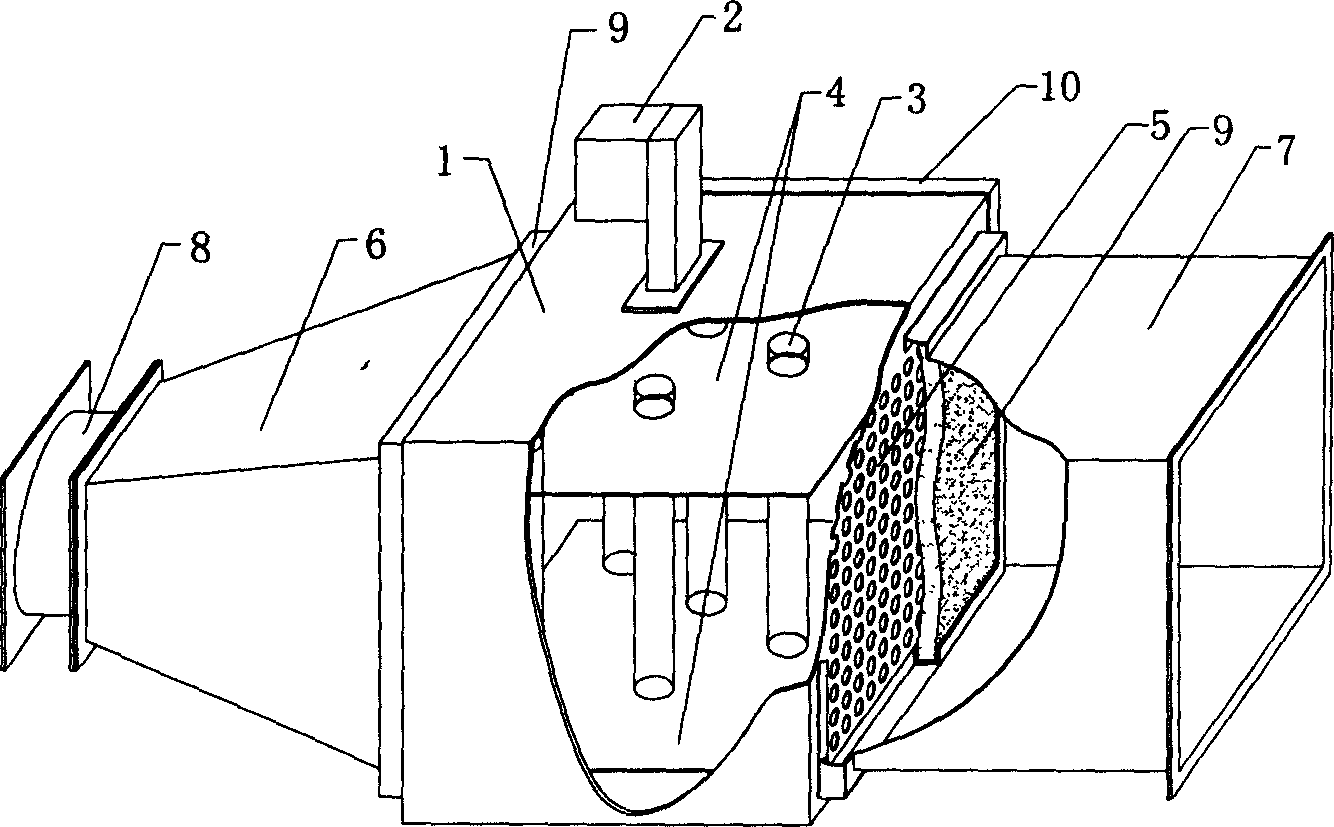

[0051] Such as figure 2 shown. A microwave cavity 1 with a volume of about 26.6 liters is selected (the internal dimensions of the cavity are 320 mm wide, 260 mm high, and 320 mm deep). Eight linear quartz lamp tubes 3 with a diameter of 15 mm and a length of 250 mm are selected. The inner cavity 12 of the lamp tube is filled with an appropriate amount of neon gas, and 1.5 mg of solid mercury 13 is added; the material of the lamp tube shell 11 is mainly high-purity quartz, and a small amount of titanium metal is mixed to form a microwave electrodeless discharge ultraviolet lamp. Tube 3. These eight microwave electrodeless discharge ultraviolet lamp tubes 3 have no electrode, no filament, no power supply, and the light transmission window is at 254nm. Select two rectangular (width 300mm, length 280mm) plastic plates with equal area. There are eight holes with a diameter of 15mm on each of the two parallel plates. The holes are evenly distributed on the plates. The two plate...

Embodiment 2

[0061] The same place as in Embodiment 1 will not be described again, and the difference is that:

[0062]The microwave electrodeless discharge ultraviolet lamp tube 3 is "H" type, with a diameter of 20mm, two parallel sections with a length of 250mm, and a section connected in the middle with a length of 260mm. The inner cavity 12 of the lamp tube is filled with an appropriate amount of krypton gas, and 4 mg of liquid mercury 13 is added. Five microwave electrodeless discharge ultraviolet lamp tubes 3 are used. Five lamp tubes are placed in the microwave cavity 1 in parallel, perpendicular to the direction of the air inlet pipe 6, and perpendicular to the horizontal plane, and the distance between the two lamp tubes is 50mm. The lamp tube is fixed with clips, and the ultraviolet lamp tube support 4 is not adopted. The microwave electrodeless discharge ultraviolet lamp tube 3 is directly exposed to the microwave cavity 1 . The air inlet pipe 6 is a straight pipe, and the ai...

Embodiment 3

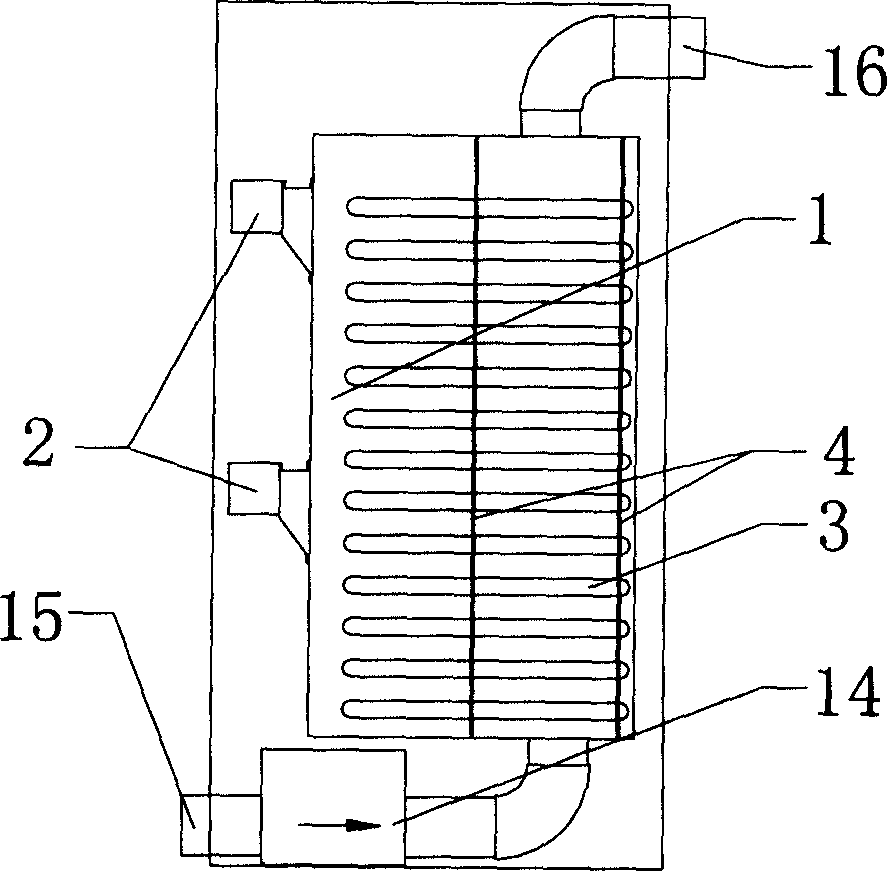

[0068] The foregoing embodiments are for disinfecting and sterilizing the air, and the present embodiment is for disinfecting and sterilizing the water. Such as image 3 shown. The same technical content as Embodiment 1 and Embodiment 2 will not be described again, and the difference is that:

[0069] The water inlet pipe 15 is on the right side below the microwave chamber 1, and the water outlet pipe 16 is on the right side above the microwave chamber 1. A water pump 14 is connected to the water inlet pipe 15, and water flows through the microwave chamber 1 from bottom to top under the action of the water pump 14. Two sets of microwave generators 2 connected to the microwave cavity 1 are installed on the left side of the microwave cavity 1, and the output microwave power of each set of microwave generators 2 is 300W. Twenty-six microwave electrodeless discharge ultraviolet lamp tubes 3 were used. Each microwave electrodeless discharge ultraviolet lamp tube 3 is an unclosed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com