Package method for high-gamut white-light quantum-dot light emitting diode (LED)

A packaging method and technology of red light quantum dots, which are applied in the field of white LED backlight, can solve problems such as difficult large-scale industrialization, difficult curing of packaging glue, and damage to packaging glue, so as to reduce difficulty and product defect rate, improve quality, and inspire high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

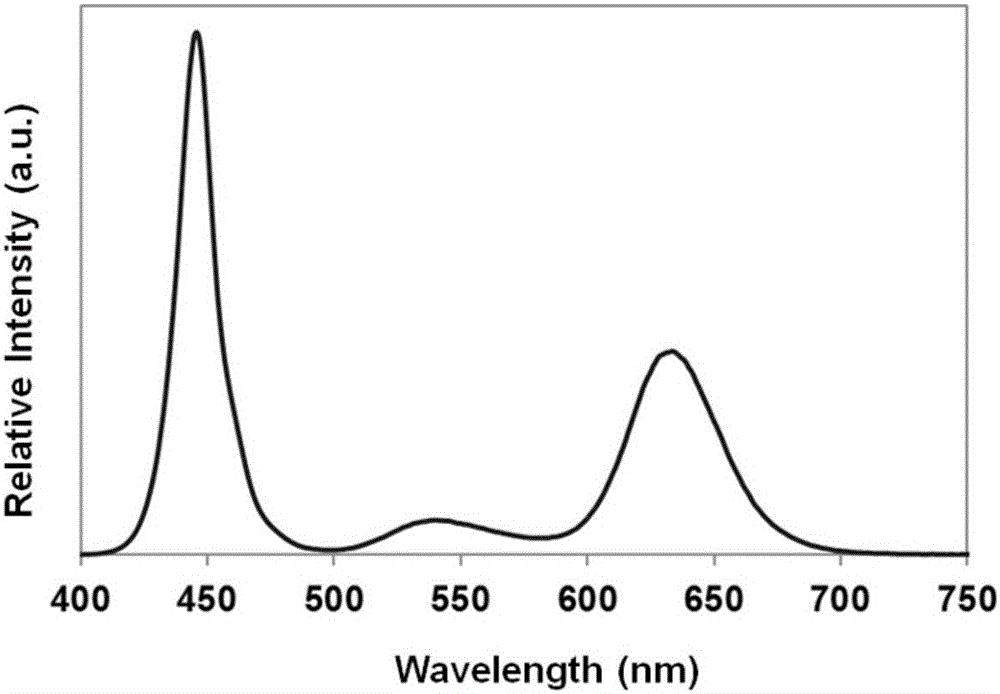

Embodiment 1

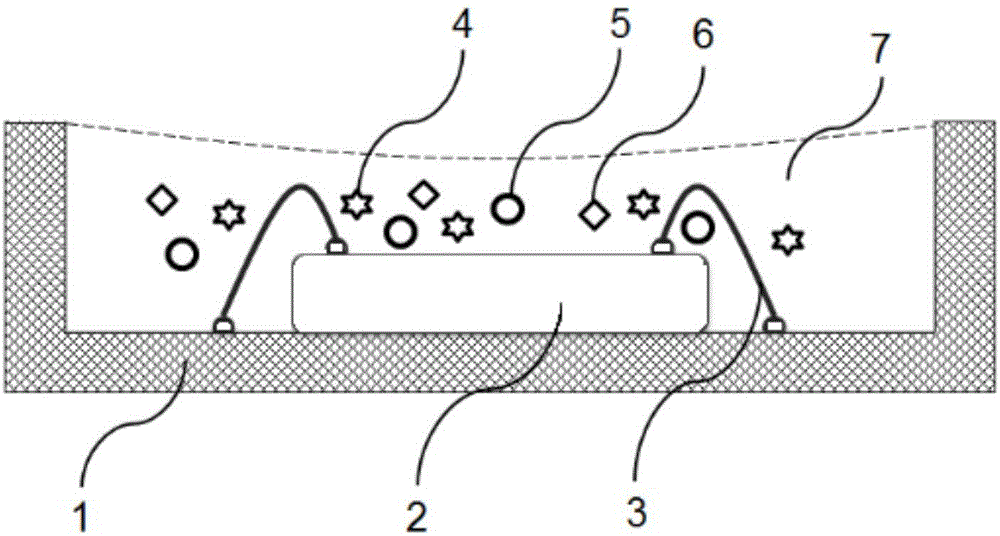

[0035] This embodiment provides a method for packaging high color gamut white light quantum dot LEDs, including the following steps:

[0036] a. Add 50 parts by weight of organic solvent n-hexane to 1 part by weight of BaS red light quantum dot phosphor powder with a peak emission wavelength of 600nm to obtain a red light quantum dot solution; to 1 part by weight of AgInS with a peak emission wavelength of 430nm 2 Add 50 parts by weight of organic solvent cyclohexane to the blue light quantum dot fluorescent powder to obtain a blue light quantum dot solution. 6nm, blue light quantum dot phosphor particle size is 4nm;

[0037] b. ultrasonically treating the red light quantum dot solution and the blue light quantum dot solution respectively at a water bath temperature of 25° C. at a frequency of 15 KHz for 10 minutes to obtain a clear quantum dot solution;

[0038] c. Add 1 part by weight of the blue light quantum dot solution to 1 part by weight of the red light quantum dot so...

Embodiment 2

[0044] This embodiment provides a method for packaging high color gamut white light quantum dot LEDs, including the following steps:

[0045] a. To 1 part by weight of NaCl and In with a peak emission wavelength of 660nm 2 o 3 Add 2000 parts by weight of an organic solvent n-octane to the red light quantum dot fluorescent powder to obtain a red light quantum dot solution; add 1500 parts by weight of an organic solvent toluene, two Chlorotoluene to obtain a blue light quantum dot solution, the particle size of the red light quantum dot fluorescent powder is 8nm, and the particle size of the blue light quantum dot fluorescent powder is 3nm, both of which are commercially available fluorescent powder;

[0046] b. ultrasonically treating the red light quantum dot solution and the blue light quantum dot solution respectively at a water bath temperature of 45° C. at a frequency of 120 KHz for 90 minutes to obtain a clear quantum dot solution;

[0047] c. Add 50 parts by weight of ...

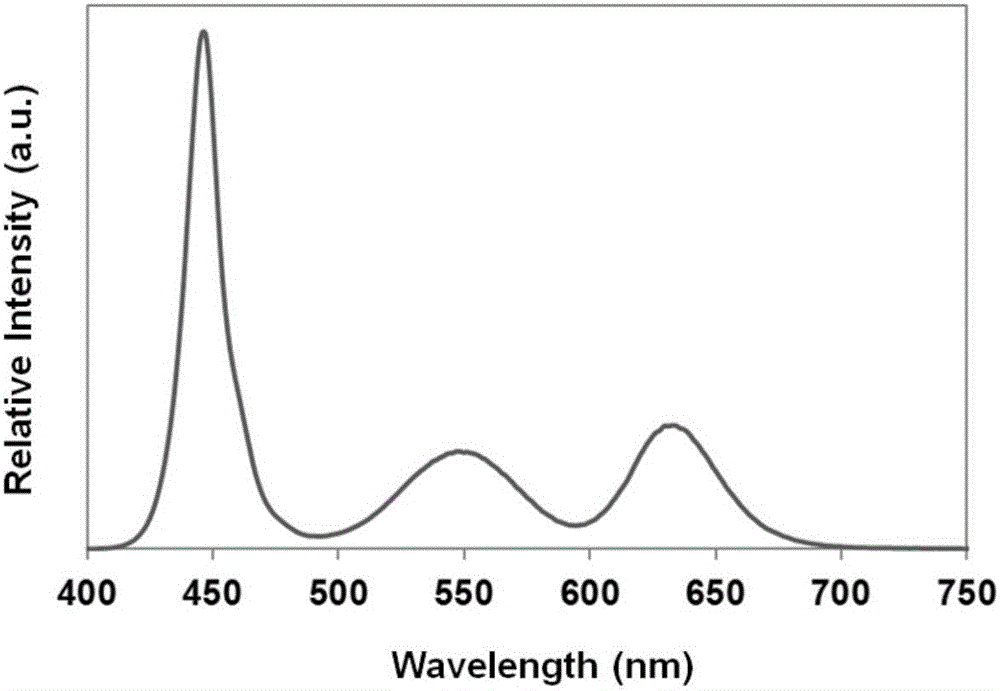

Embodiment 3

[0053] This embodiment provides a method for packaging high color gamut white light quantum dot LEDs, including the following steps:

[0054] a. Add 150 parts by weight of organic solvent methylene chloride to 1 part by weight of InP, CdS, and CdSe red light quantum dot phosphors with a peak emission wavelength of 620nm to obtain a red light quantum dot solution; to 1 part by weight of CdTe with a peak emission wavelength of 450nm , ZnS, ZnSe blue light quantum dot fluorescent powder, add 50 parts by weight organic solvent chloroform, obtain blue light quantum dot solution, described red light quantum dot fluorescent powder and blue light quantum dot fluorescent powder are commercially available fluorescent powder, wherein red light quantum dot The particle size of phosphor powder is 6nm, and the particle size of blue light quantum dot phosphor powder is 3nm;

[0055] b. ultrasonically treating the red light quantum dot solution and the blue light quantum dot solution respecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| fluorescence wavelength | aaaaa | aaaaa |

| fluorescence wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com