Preparation method of high-permeability mica tape

A technology of less glue mica tape and air permeability, which is applied in the field of preparation of high air permeability and less glue mica tape, can solve the problems of poor air permeability, poor wrapping processability, and inability to fully penetrate the less glue mica tape, and achieves complete shortening. The effect of soaking time, improving electrical performance, reducing pollution and waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation of embodiment 1 highly gas-permeable little rubber mica tape

[0040] Use solvent-free resin powder as an adhesive to prepare a low-adhesive mica tape with high air permeability and high mica content. The materials required for the preparation process are as follows:

[0041] 1) Epoxy / polyester resin powder, the epoxy equivalent of the resin is 890g / equivalent, the acid value is 20mg-KOH / g, and the softening point is 85°C.

[0042] 2) The mass per unit area is 178g / m 2 Muscovite paper, and pre-spray 1g / m 2 The zinc naphthenate accelerator is used to pretreat the mica paper, and the air permeability is 205s / 100cm 3 .

[0043] 3) The mass per unit area is 23.5g / m 2 glass cloth, the density of warp and weft is 25 / cm and 20 / cm respectively, and pre-spray 1.5g / m 2 The glass cloth is pretreated with zinc naphthenate.

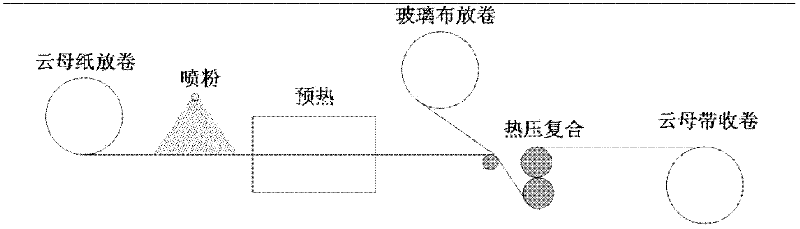

[0044] The specific process of preparing high air permeability, high mica content and less rubber mica tape is as attached figure 1 Show...

Embodiment 2

[0046] The preparation of embodiment 2 highly gas-permeable less rubber mica tapes

[0047] Use solvent-free resin powder as an adhesive to prepare a low-adhesive mica tape with high air permeability and high mica content. The materials required for the preparation process are as follows:

[0048] 1) Epoxy resin powder, the epoxy equivalent of the resin is 1100g / equivalent, and the softening point is 105°C.

[0049] 2) The mass per unit area is 178g / m 2 Muscovite paper, and pre-spray 1g / m 2 The zinc naphthenate accelerator is used to pretreat the mica paper, and the air permeability is 123s / 100cm 3 .

[0050] 3) The mass per unit area is 23.5g / m 2 glass cloth, the density of warp and weft is 25 / cm and 20 / cm respectively, and pre-spray 1.5g / m 2 The glass cloth is pretreated with zinc naphthenate.

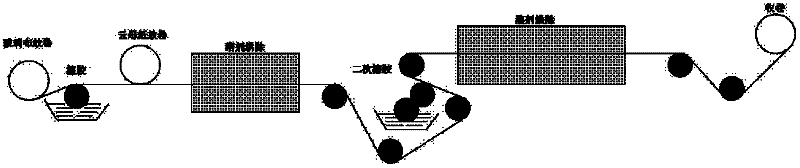

[0051] The specific process of preparing high air permeability, high mica content and less rubber mica tape is as attached figure 2 Shown: After the mica paper is unwound, it...

Embodiment 3

[0053] Embodiment 3 The preparation of high air permeability less rubber mica tape

[0054] Use solvent-free resin powder as an adhesive to prepare a low-adhesive mica tape with high air permeability and high mica content. The materials required for the preparation process are as follows:

[0055] 1) Epoxy / polyester resin powder, the epoxy equivalent of the resin is 620g / equivalent, the acid value is 20mg-KOH / g, and the softening point is 75°C.

[0056] 2) The mass per unit area is 178g / m 2 Muscovite paper, and pre-spray 1g / m 2 The mica paper is pretreated with the zinc isooctanoate accelerator, and the air permeability is 146s / 100cm 3 .

[0057] 3) The mass per unit area is 23.5g / m 2 glass cloth, the density of warp and weft is 25 / cm and 20 / cm, and pre-spray 1g / m 2 The zinc isooctanoate accelerator is used to pretreat the glass cloth.

[0058] The specific process of preparing high air permeability, high mica content and less rubber mica tape is as attached figure 2 S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com