Leather fatting agent

A technology of leather fatliquor and reagent, which is applied in the field of leather fatliquor, can solve the problems of poor toughening performance, achieve toughness maintenance, reduce hydrophilic groups, and avoid performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

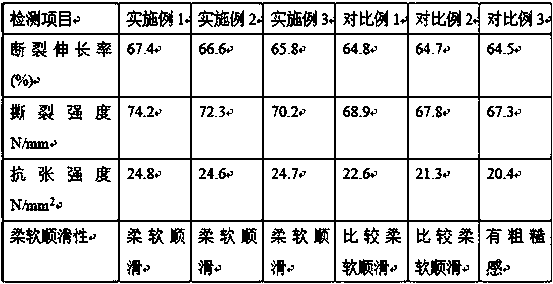

Examples

preparation example Construction

[0029] The preparation method of emulsified active liquid, comprises the steps:

[0030] (1) Take the pretreated waste oil and add methanol and concentrated sulfuric acid at a mass ratio of 1:3~6:0.01 to mix, stir at 60~70°C at 250~300r / min for 20~45min, and keep warm for 1~3h to obtain the pretreated waste oil. For the esterified product, take the pre-esterified product and add reagent A at a mass ratio of 10~15:2 to mix, move to a centrifuge, and centrifuge at 3000~4000r / min for 10~15min, take the upper oily phase and wash it with water for 2~4 times to obtain the pre-esterified product. Esterified waste oil;

[0031] (2) According to the mass ratio of 1:6~8:0.01, take pre-esterified waste oil, methanol, and sodium hydroxide and mix them, and reflux at 60~80°C for 2~4 hours to obtain the reactant. Take the reactant in a centrifuge at 2000~ Centrifuge at 3000r / min for 6~10min, take the fat phase according to the mass ratio of 12~18:0.3~0.7, add the catalyst and mix, react at...

Embodiment 1

[0040] Auxiliary: Mix hydrogenated castor oil, microcrystalline paraffin, and gelatin at a mass ratio of 5:1:0.1 to obtain the adjuvant.

[0041] Surfactant: Mix sodium dodecylbenzenesulfonate and cetyltrimethylammonium bromide in a mass ratio of 1:3 to obtain a surfactant.

[0042] Reagent A: Mix 4°C water and acetone at a mass ratio of 8:3 to obtain Reagent A.

[0043] Reagent B: Mix 12% sodium bicarbonate solution and sodium citrate at a ratio of 12:1 by mass fraction to obtain reagent B.

[0044] Plant essential oil: Wintersweet flower essential oil.

[0045] Pretreatment of gutter oil: take gutter oil and filter it, at 50°C, take the filtrate and mix it with deionized water at a mass ratio of 1:10, stir it with 300r / min magnetic force for 30min, let it stand at room temperature for 1h, at 40°C, take the upper oil phase and press Mix with white clay at a mass ratio of 6:1, stir magnetically at 500r / min for 35min, filter with suction, take the filtrate and vacuumize it to...

Embodiment 2

[0058] Auxiliary: Mix hydrogenated castor oil, microcrystalline paraffin, and gelatin at a mass ratio of 8:1:0.1 to obtain the adjuvant.

[0059] Surfactant: Mix sodium dodecylbenzenesulfonate and cetyltrimethylammonium bromide in a mass ratio of 1:6 to obtain a surfactant.

[0060] Reagent A: Mix 8°C water and acetone at a mass ratio of 15:3 to obtain Reagent A.

[0061] Reagent B: Mix 12% sodium bicarbonate solution and sodium citrate at a ratio of 18:1 by mass to obtain reagent B.

[0062] Plant essential oil: Jasmine essential oil.

[0063] Pretreatment of gutter oil: Take gutter oil and filter it at 65°C, take the filtrate and mix it with deionized water at a mass ratio of 1:15, stir it with a magnetic force at 500r / min for 50min, let it stand at room temperature for 3h, at 55°C, take the upper oil phase and press Mix with white clay at a mass ratio of 10:1, stir with 800r / min magnetic force for 50min, filter with suction, take the filtrate and vacuumize to remove moist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com