Treatment method for all-vanadium redox flow battery electrode

The technology of an all-vanadium redox flow battery and a processing method is applied in the field of treatment of electrodes for all-vanadium redox flow batteries, and can solve the problems of catalyst falling off, increasing the specific surface area of carbon electrodes, electrochemical reaction active sites, and reducing reaction activity. , to achieve the effects of low cost, increased effective reaction area and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

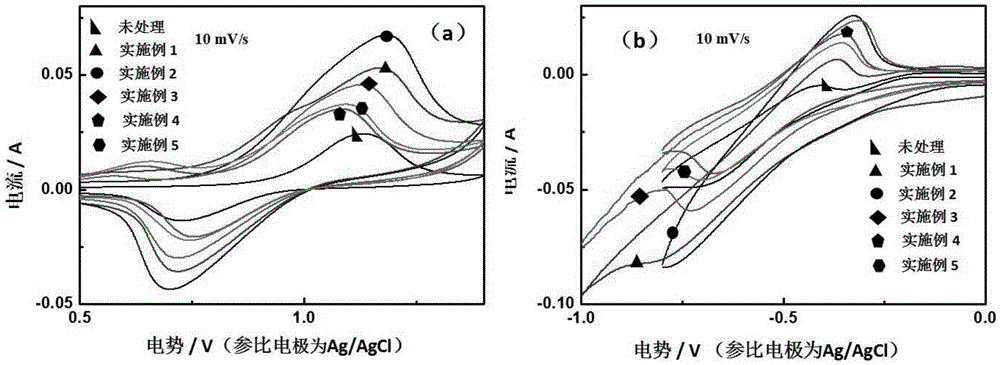

[0026] Dissolve 0.1 g of analytically pure KOH in distilled water, soak a 6 mm thick carbon felt in the above solution and ultrasonically soak for 30 minutes, take out the carbon felt and dry it in a muffle furnace at 80°C for 6 hours. The carbon felt dried in the muffle furnace was placed in a tube furnace, and under the protection of nitrogen, the temperature was raised to 700 °C at a rate of 10 °C / min, the activation reaction was kept for 20 min, and then naturally cooled to room temperature. Take out the high-temperature activated carbon felt and place it in a 150ml beaker, add 100mL of 1.0mol / L HCl, and ultrasonically wash it for 30min. After pouring out the solution, add 100mL distilled water, ultrasonically wash for 10min, and ultrasonically change and wash with distilled water 5 times until the pH value of the solution is neutral, soak in 200ml distilled water for 24h, then take out the carbon felt and place it in a muffle furnace for 12h at 80°C , to obtain an electro...

Embodiment 2

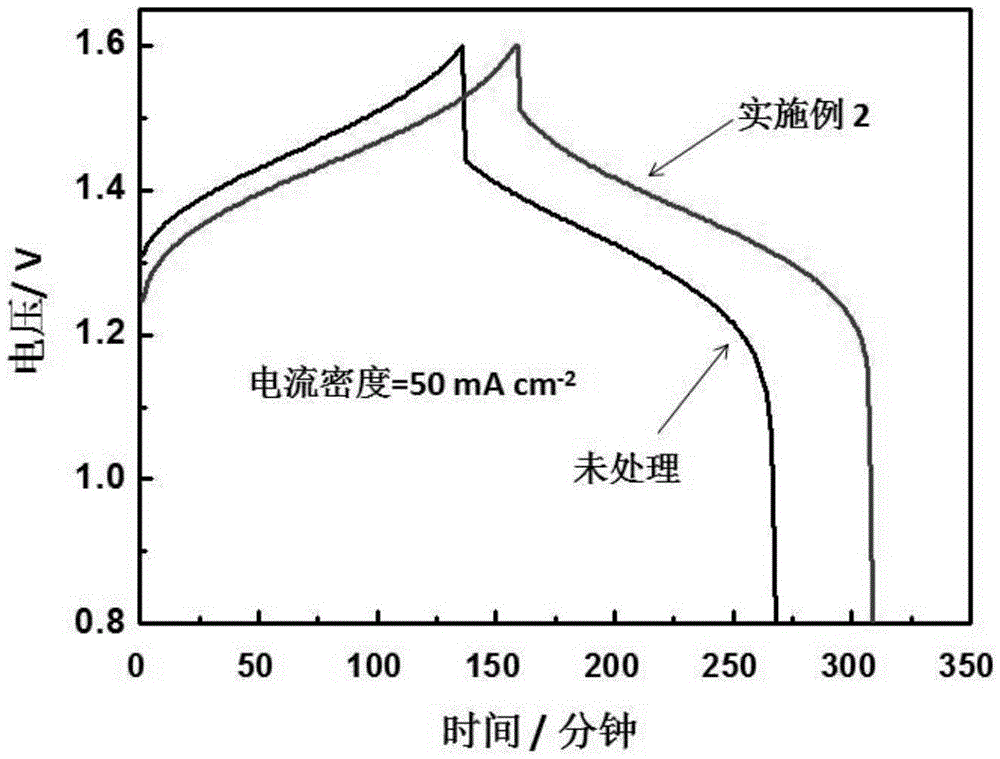

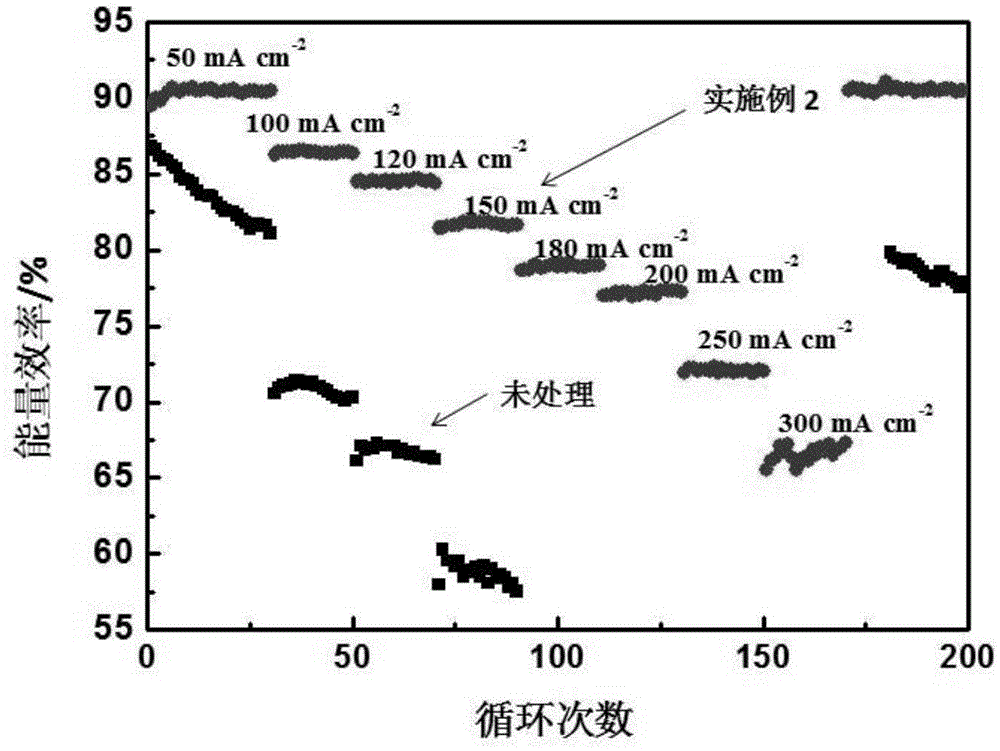

[0028] Dissolve 0.5 g of analytically pure KOH in distilled water, soak a carbon felt with a thickness of 5 mm in the above solution for 60 minutes, and take out the carbon felt and dry it in a vacuum oven at 100°C for 6 hours. The carbon felt dried in a vacuum drying oven was placed in a tube furnace, and under the protection of nitrogen, the temperature was raised to 800 °C at a rate of 8 °C / min, the activation reaction was kept for 30 min, and naturally cooled to room temperature. Take out the high-temperature activated carbon felt and place it in a 150ml beaker, add 100mL of 1.0mol / L HCl, and ultrasonically wash it for 30min. After pouring out the solution, add 100mL distilled water, ultrasonically wash for 10min, change and wash 5 times with distilled water ultrasonically until the pH value of the solution is neutral, soak in 200ml distilled water for 24h, then take out the carbon felt and place it in a vacuum drying oven for 12h at 100°C , to obtain an electrode that can...

Embodiment 3

[0030] Dissolve 1.0 g of analytically pure KOH in distilled water, soak graphite felt with a thickness of 6 mm in the above solution for 90 minutes, and then take out the graphite felt and dry it in a muffle furnace at 100°C for 6 hours. The graphite felt dried in the muffle furnace was placed in a tube furnace, and under the protection of argon, the temperature was raised to 900°C at a rate of 10°C / min, kept for 30 minutes for activation reaction, and then naturally cooled to room temperature. Take out the high-temperature activated graphite felt and place it in a 150ml beaker, add 100mL of 1.0mol / L HCl, and ultrasonically wash it for 30min. After pouring out the solution, add 100mL distilled water, ultrasonically wash for 10min, change and wash 5 times with distilled water ultrasonically until the pH value of the solution is neutral, soak in 200ml distilled water for 24h, then take out the graphite felt and place it in a vacuum drying oven for 12h at 100°C , to obtain an ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com