Preparation method of iron-clad aluminum type composite powder and product thereof

A technology of composite powder and aluminum type, which is applied in the direction of compressed gas generation, offensive equipment, explosives, etc., can solve the problems of difficult to control manufacturing costs, poor coating uniformity, complex processing equipment, etc., to solve incomplete combustion , easy quality control, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

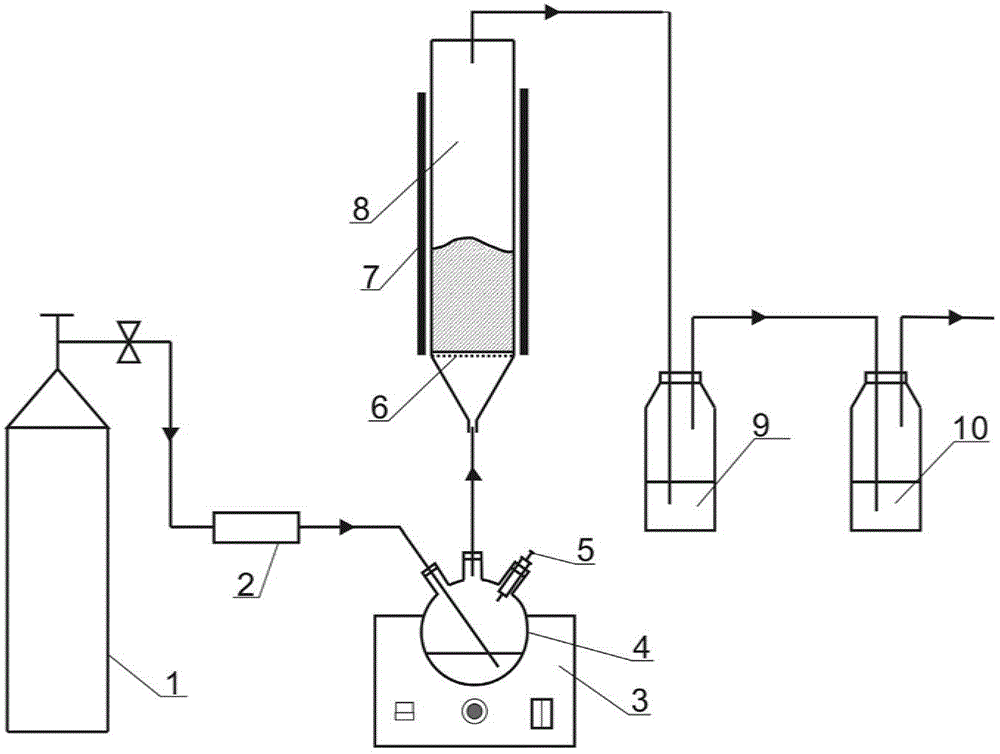

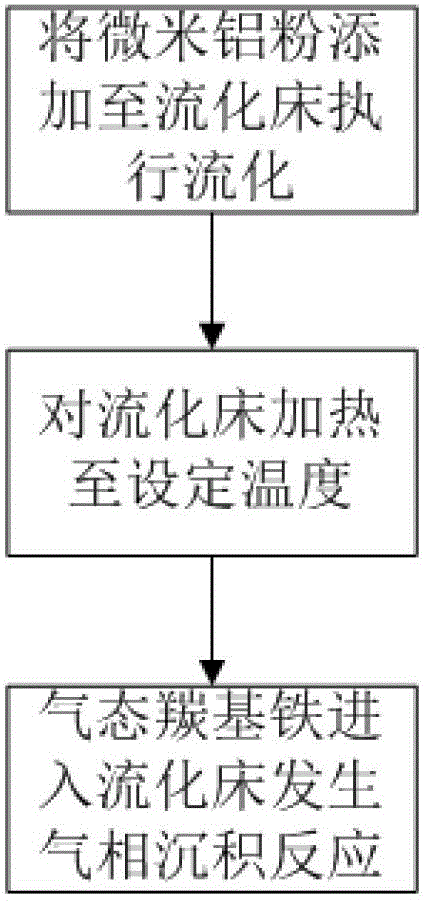

Method used

Image

Examples

Embodiment 1

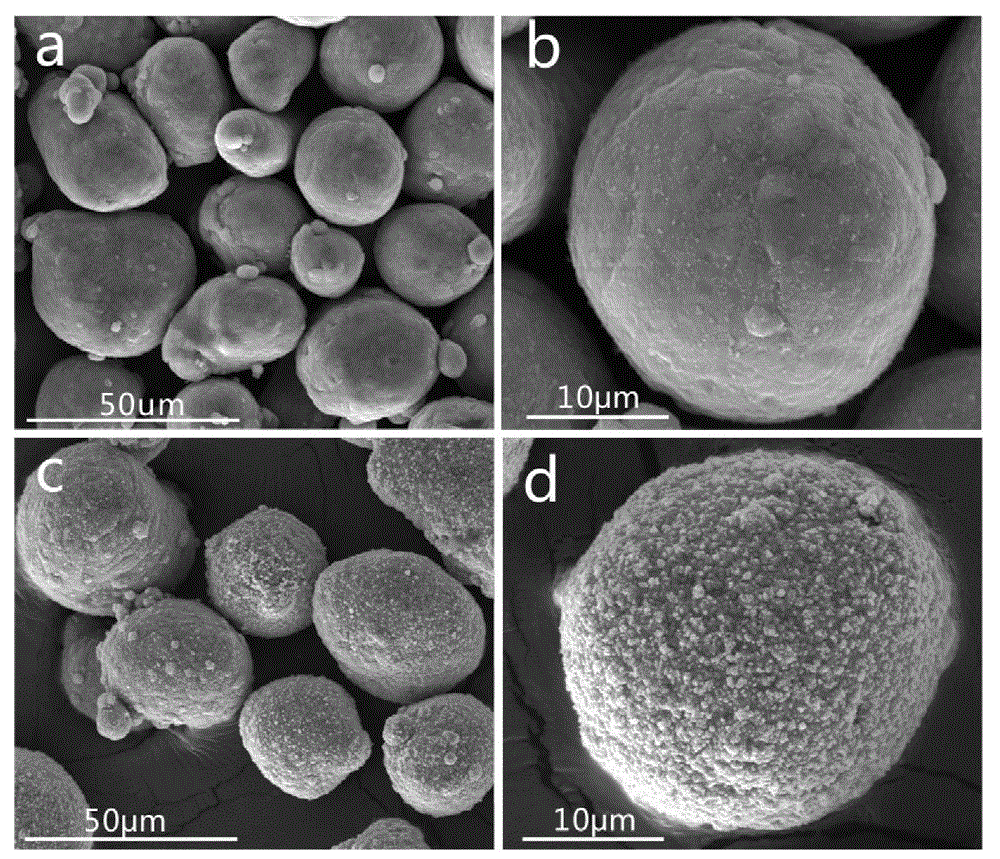

[0041] Add 15g of aluminum powder with an average size of 29 microns to the fluidized bed and feed argon as a carrier gas, adjust the gas velocity of argon to 0.7L / min, thus perform the fluidization process of the aluminum powder, in this process In the process, the ratio between the height of the aluminum powder added to the fluidized bed and the diameter of the fluidized bed itself, that is, the height-to-diameter ratio, is controlled to be 3; then, continue to feed argon so that the air in the fluidized bed is exhausted, and then close Connect the fluidized bed with the outside air, and heat the fluidized bed to a temperature of 300°C; when the fluidized bed reaches 300°C, add 15ml of carbonyl iron into the bubbler and heat it to 100°C, so that Carbonyl iron volatilizes and is brought into the fluidized bed by argon gas for vapor phase deposition reaction, thereby producing iron-clad aluminum composite powder products in which iron is coated on the surface of micron aluminum...

Embodiment 2

[0043] Add 10g of aluminum powder with an average size of 7 microns in the fluidized bed and feed argon as a carrier gas, adjust the gas velocity of argon to 0.5L / min while stirring the aluminum powder, thereby performing the aluminum powder Fluidization process, in this process, the ratio between the height of the aluminum powder added to the fluidized bed and the diameter of the fluidized bed itself, that is, the height-to-diameter ratio is controlled to be 2.0; then, continue to feed argon to make the fluidized bed The air is exhausted, then the connection between the fluidized bed and the outside air is closed, and the fluidized bed is heated to a temperature of 320°C; when the fluidized bed reaches 320°C, 22ml of carbonyl iron is added to the bubbler And heated to 50°C, so that the carbonyl iron volatilizes and is brought into the fluidized bed by argon gas for vapor phase deposition reaction, thereby producing an iron-clad aluminum composite powder product in which iron i...

Embodiment 3

[0045] Add 8g of aluminum powder with an average size of 2 microns in the fluidized bed and pass into argon as a carrier gas, adjust the gas velocity of argon to 0.4L / min and perform a stirring operation on the aluminum powder, thereby performing the aluminum powder Fluidization process, in this process, the ratio between the height of the aluminum powder added to the fluidized bed and the diameter of the fluidized bed itself, that is, the height-to-diameter ratio is controlled to be 1.5; then, continue to feed argon to make the fluidized bed The air is exhausted, then the connection between the fluidized bed and the outside air is closed, and the fluidized bed is heated to a temperature of 280°C; when the fluidized bed reaches 280°C, 15ml of carbonyl iron is added to the bubbler And heated to 70°C, so that the carbonyl iron volatilizes and is brought into the fluidized bed by argon gas for vapor phase deposition reaction, thereby producing iron-clad aluminum composite powder p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com