Cladding type quantum dot LED lamp bead packaging method

A technology of LED lamp beads and packaging method, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of difficulty in large-scale industrialization, low light conversion efficiency, complex process, etc., to reduce product defect rate, phosphor powder, etc. The effect of low concentration and high excitation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

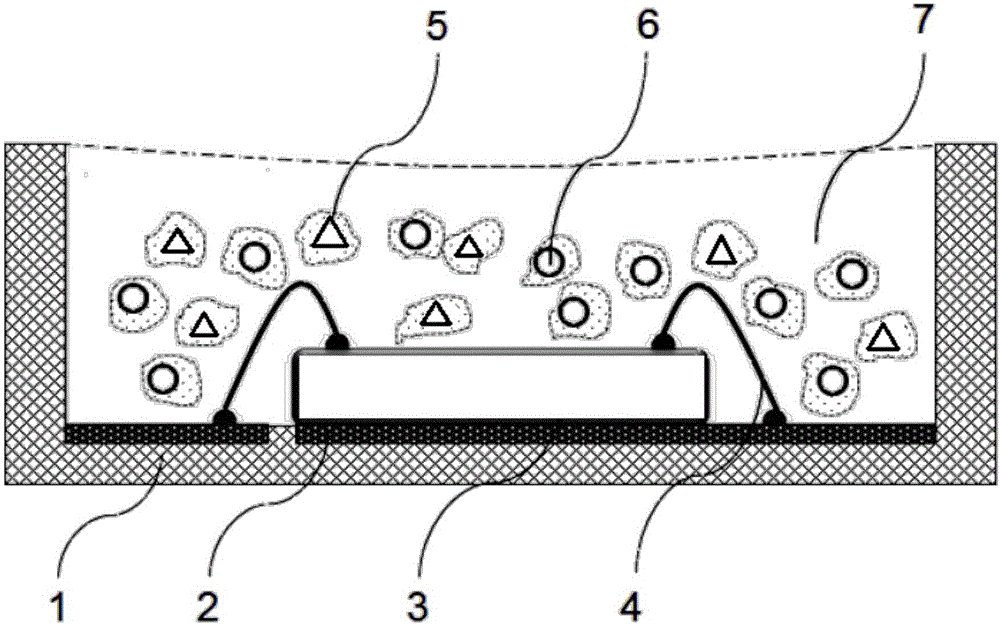

Method used

Image

Examples

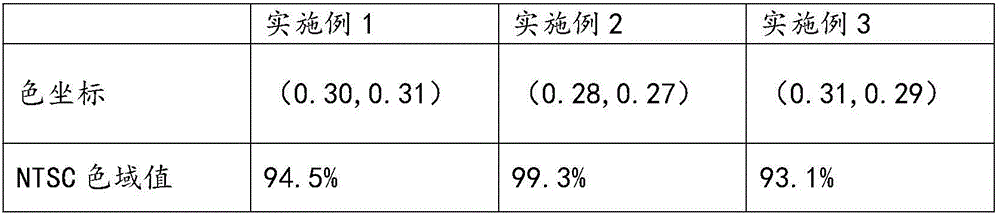

Embodiment 1

[0033] 1) Weigh 0.75g of phosphate red phosphor powder with an emission wavelength of 635nm, and weigh 0.04g of GaSe green quantum dot phosphor powder with an emission wavelength of 537nm, and place them in a container together.

[0034] 2) Weigh 1.50 g of epoxy resin, pour it into the luminescent material weighed in step 1), and carry out vacuum defoaming and stirring to obtain quantum dot fluorescent glue.

[0035] 3) Put the quantum dot fluorescent glue obtained in step 2) into an oven and bake at 150°C for 0.5h to cure the quantum dot fluorescent glue.

[0036] 4) The baked and cured fluorescent glue obtained in step 3) is placed in an agate mortar and ground, and the quantum dot fluorescent glue is ground into particles.

[0037] 5) Put the particles obtained in step 4) into a planetary ball mill, add an appropriate amount of alcohol to carry out wet ball milling, and control the speed of the ball mill to 240rpm. Dry at 60° C. after ball milling to obtain uniformly dispe...

Embodiment 2

[0042] 1) Weigh 0.17g of MgS red light quantum dot phosphor powder with an emission wavelength of 644nm, 0.10g of GaAs green light quantum dot phosphor powder with an emission wavelength of 541nm, and 0.58g of aluminate blue light phosphor with an emission wavelength of 458nm, together in a container.

[0043] 2) Weigh 2.00 g of epoxy resin, pour it into the luminescent material weighed in step 1), and carry out vacuum defoaming and stirring to obtain quantum dot fluorescent glue.

[0044] 3) Put the quantum dot fluorescent glue obtained in step 2) into an oven and bake at 120° C. for 1 hour to cure the quantum dot fluorescent glue.

[0045] 4) Put the baked and cured fluorescent glue obtained in step 3) into a stainless steel mortar and grind it to grind the quantum dot fluorescent glue into particles.

[0046] 5) Put the particles obtained in step 4) into a planetary ball mill, add an appropriate amount of alcohol to carry out wet ball milling, and control the speed of the ...

Embodiment 3

[0051] 1) Weigh 3.45g of fluoride red phosphor powder with an emission wavelength of 620nm, and weigh 0.12g of MgTe green quantum dot phosphor powder with an emission wavelength of 537nm, and place them in a container together.

[0052] 2) Weigh 2.75g of epoxy resin, pour it into the luminescent material weighed in step 1), and carry out vacuum defoaming and stirring to obtain quantum dot fluorescent glue.

[0053] 3) Put the quantum dot fluorescent glue obtained in step 2) into an oven and bake at 100° C. for 1 hour to cure the quantum dot fluorescent glue.

[0054] 4) The baked and cured fluorescent glue obtained in step 3) is placed in an agate mortar and ground for grinding, and the quantum dot fluorescent glue is ground into particles.

[0055] 5) Put the particles obtained in step 4) into a planetary ball mill, add an appropriate amount of alcohol to carry out wet ball milling, and control the speed of the ball mill to 2000rpm. After ball milling, dry at 40° C. to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com