Phosphor powder containing lutetium carbonitride, its preparation method and device containing the phosphor powder

A carbonitride and phosphor technology, applied in the field of luminescent materials, can solve problems such as poor stability, poor light color tuning, and single emission spectrum, and achieve excellent thermal quenching performance and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] According to the chemical formula of phosphor (Lu 0.98 , Ce 0.02 ) 2 Si 3.8 al 0.2 N 6.2 C 0.8 , respectively weighed 3.509g Lu 2 o 3 , 1.599g Si 3 N 4 , 0.074g AlN, 0.477g C, 0.061g CeO 2 . After fully mixing and grinding, the mixture was placed in a tungsten crucible, under N 2 The sintering is carried out in the atmosphere, the sintering temperature is 1750° C., the sintering time is 10 hours, and it is naturally cooled with room temperature. After the calcined product is crushed, graded, washed, dried and sieved, the composition is obtained (Lu 0.98 , Ce 0.02 ) 2 Si 3.8 al 0.2 N 6.2 C 0.8 of fluorescent powder.

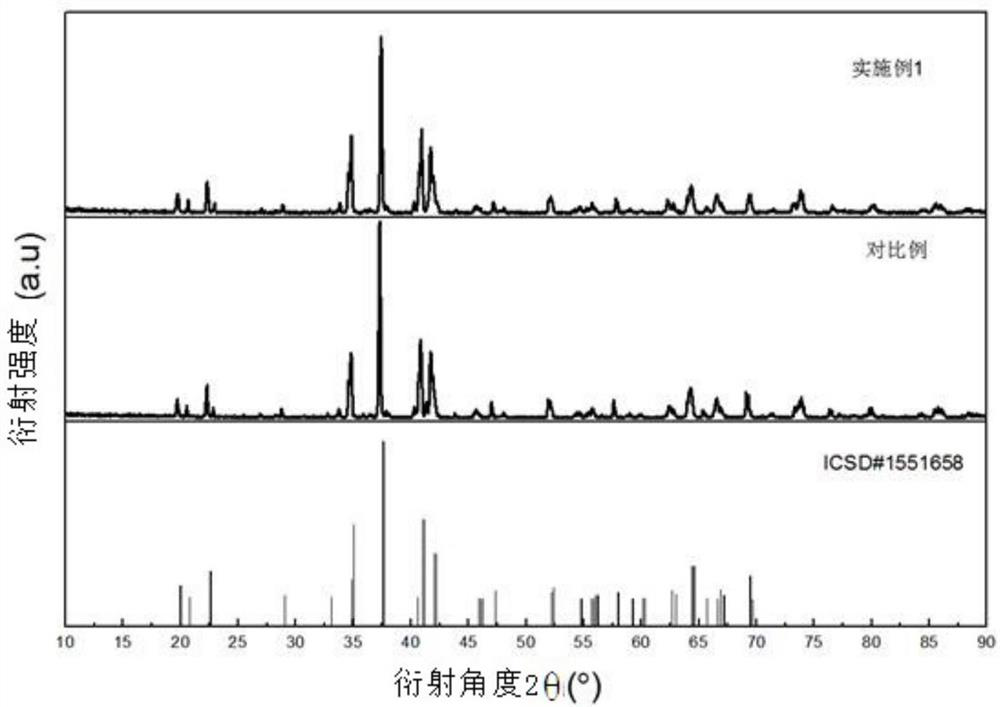

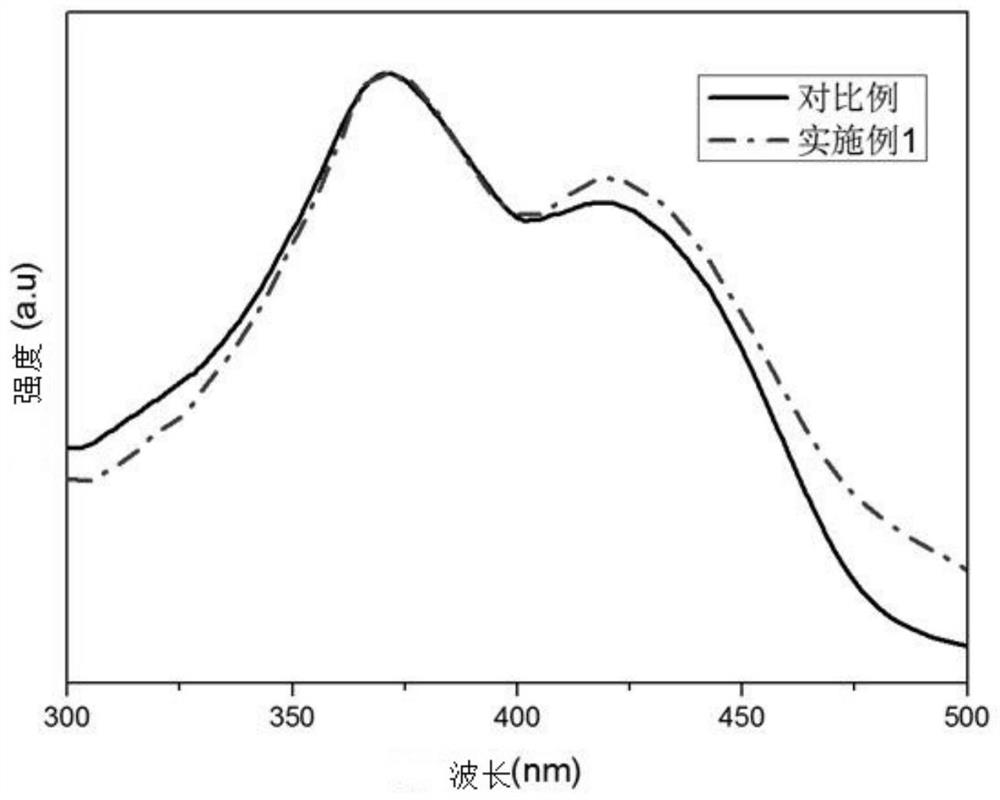

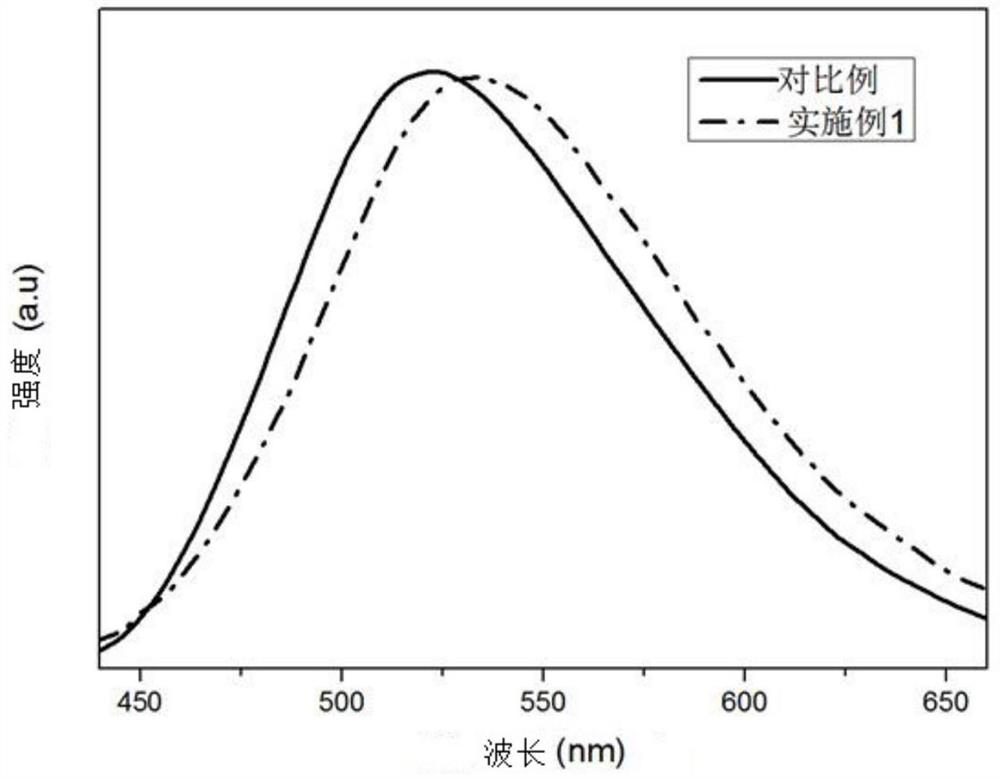

[0052] figure 1 Among them, its phase analysis shows that the crystal structure of the product obtained in this embodiment and the Ho 2 Si 4 N 6 The crystal structure of C is similar. figure 1 Among them, the abscissa is 2θ, which means that the X-ray diffraction spectrum is scanned by the X-ray diffractometer at an angle of 2θ to th...

Embodiment 2

[0056] According to the chemical formula Lu 1.95 Ce 0.05 Si 3.4 al 0.6 N 6.6 C 0.4 The stoichiometric ratio, accurately weighed LuN (purity 99.9%), Si 3 N 4 (purity 99.9%), AlN (purity 99.9%), SiC (purity 99.9%) and CeN (purity 99.99%) raw materials, and mixed to form a mixed raw material. The mixed raw materials were thoroughly mixed and ground for 30 minutes in a glove box to obtain a mixture. The mixture was raised to 1700°C at a heating rate of 10°C / min, then kept at 1700°C for 10 hours, and the temperature was naturally lowered to obtain a roasted product. After the calcined product is taken out, it is broken, washed, sieved and dried to obtain the Lu of Example 2. 1.95 Ce 0.05 Si 3.4 al 0.6 N 6.6 C 0.4 Phosphor. The SEM morphology of embodiment 2 is as attached Figure 5 shown.

Embodiment 3

[0058] According to the chemical formula Lu 1.95 Ce 0.05 Si 3.9 al 0.1 N 6.1 C 0.9 The stoichiometric ratio, accurately weigh LuH 3 (purity 99.9%), Si 3 N 4 (purity 99.9%), AlN (purity 99.9%), SiC (purity 99.9%) and CeN (purity 99.99%) raw materials, and mixed to form a mixed raw material. The mixed raw materials were thoroughly mixed and ground for 30 minutes in a glove box to obtain a mixture. The mixture was raised to 1730°C at a heating rate of 10°C / min, then kept at 1730°C for 10 hours, and the temperature was naturally lowered to obtain a roasted product. After the roasted product is taken out, it is broken, washed, sieved and dried to obtain the Lu of Example 3. 1.95 Ce 0.05 Si 3.9 al 0.1 N 6.1 C 0.9 Phosphor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com