A kind of blue fluorescent powder excited by purple light LED and preparation method thereof

A technology of blue phosphor and violet light, applied in the field of blue phosphor, can solve the problems of no excitation and emission intensity, low luminous intensity, low energy consumption, etc., and achieve high commercial application value, high luminous intensity, and good matching. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] According to another aspect of the present invention, the present invention provides a method for preparing the blue phosphor excited by the above-mentioned violet LED. The method includes the following steps:

[0023] Step 1: According to the chemical structure of blue phosphor M 1-x MgSi 5 Al 10 O 27 :xEu 2+ The stoichiometric number shown, weigh the raw material MCO 3 , MgCO 3 , SiO 2 , Al 2 O 3 And Eu 2 O 3 , Mix these raw materials with flux uniformly, and put them in a mortar to grind them thoroughly;

[0024] The second step: calcining the above-mentioned ground material in a reducing atmosphere, the calcining temperature is 1100-1300°C, the calcining time is 5-10h, after calcining, it is cooled and crushed to obtain the blue phosphor of the present invention.

[0025] In the first step, the flux is selected from AlF 3 , NH 4 F, Li 2 CO 3 , H 3 BO 3 , NaCO 3 One or more of them, and preferably AlF 3 The amount of flux is 0.1wt% to 1.0wt% of the total mass of the raw mate...

Embodiment 1

[0030] Weigh 0.99molCaCO according to the chemical structure of the blue phosphor 3 , 1.0molMgCO 3 , 5.0molSiO 2 , 5.0molAl 2 O 3 , 0.005molEu 2 O 3 As a raw material, weigh 0.4wt% of the total mass of the raw material AlF flux 3 To mix with the raw materials, put the weighed raw materials and flux into a mortar to grind, grind for 10 minutes, and sieve the ground material through a 300-mesh screen to obtain the sieved material;

[0031] Place the above-mentioned sieved materials in a crucible, weigh 10wt% of the total mass of the above-mentioned raw materials, and place the activated carbon powder around the crucible where the raw materials are located, and calcinate in a reducing atmosphere created by these activated carbon powders at a calcination temperature of 1100°C. Time 10h; after calcination, take out the calcined material, after cooling and crushing, the required Ca is obtained 0.99 MgSi 5 Al 10 O 27 :0.01Eu 2+ Phosphor.

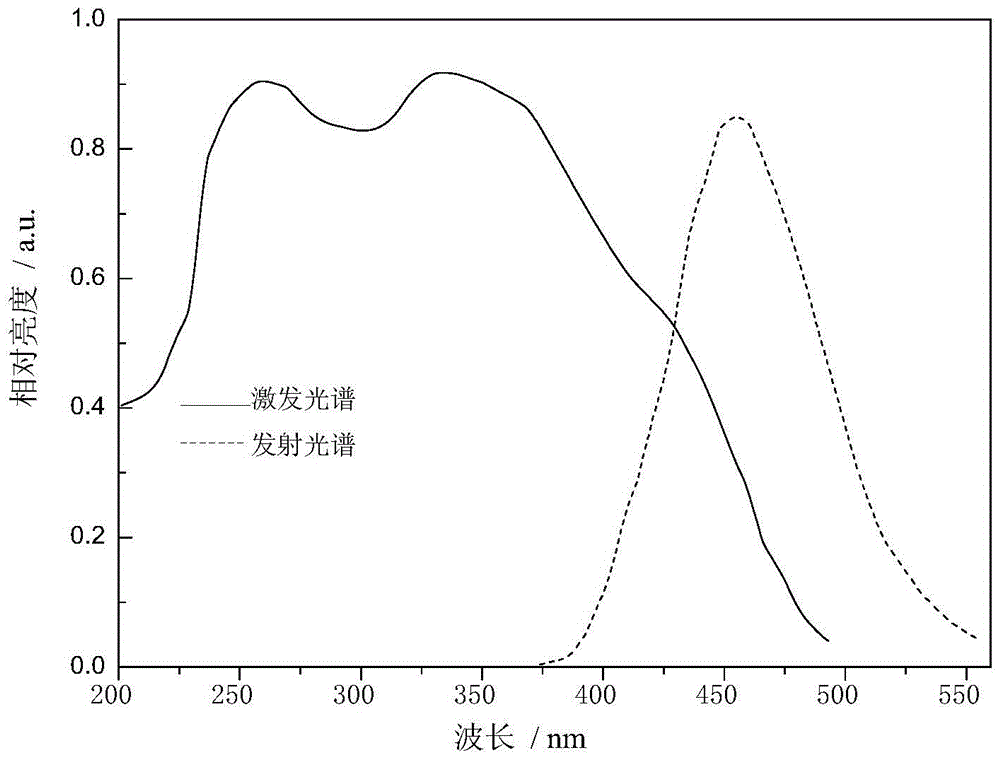

[0032] figure 1 Shows blue phosphor Ca 0.99 MgSi ...

Embodiment 2

[0034] Weigh 0.97molSrCO according to the chemical structure of the blue phosphor 3 , 1.0molMgCO 3 , 5.0molSiO 2 , 5.0molAl 2 O 3 , 0.015molEu 2 O 3 As a raw material, weigh 0.5wt% of the flux H of the total mass of the raw material 3 BO 3 To mix with the raw materials, put the weighed raw materials and flux into a mortar to grind, grind for 10 minutes, and sieve the ground material through a 300-mesh screen to obtain the sieved material;

[0035] Place the above-mentioned sieved materials in a crucible, weigh 12wt% of the total mass of the above-mentioned raw materials, and place the activated carbon powder around the crucible where the raw materials are located, and calcinate in a reducing atmosphere created by these activated carbon powders at a calcination temperature of 1150°C. Time 9h; after calcination, take out the calcined material, after cooling and crushing, the required Sr can be obtained 0.97 MgSi 5 Al 10 O 27 :0.03Eu 2+ Phosphor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| spectroscopy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com