Sc-based carbonitride phosphor and device containing phosphor

A carbonitride and phosphor technology, applied in the field of luminescent materials, can solve the problems of rare earth ions, coordination variation, etc. that have not yet been seen, and achieve the effects of good physical and chemical stability and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

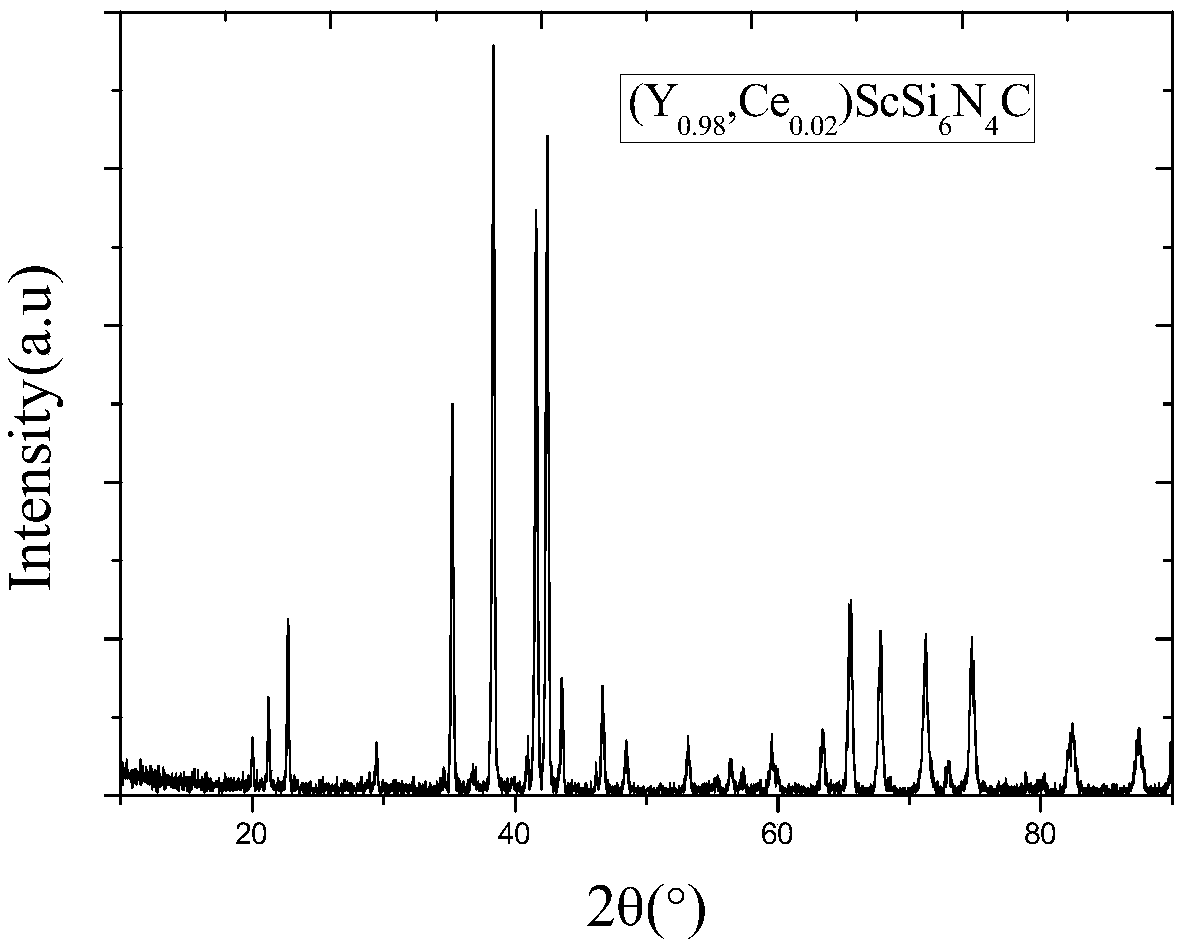

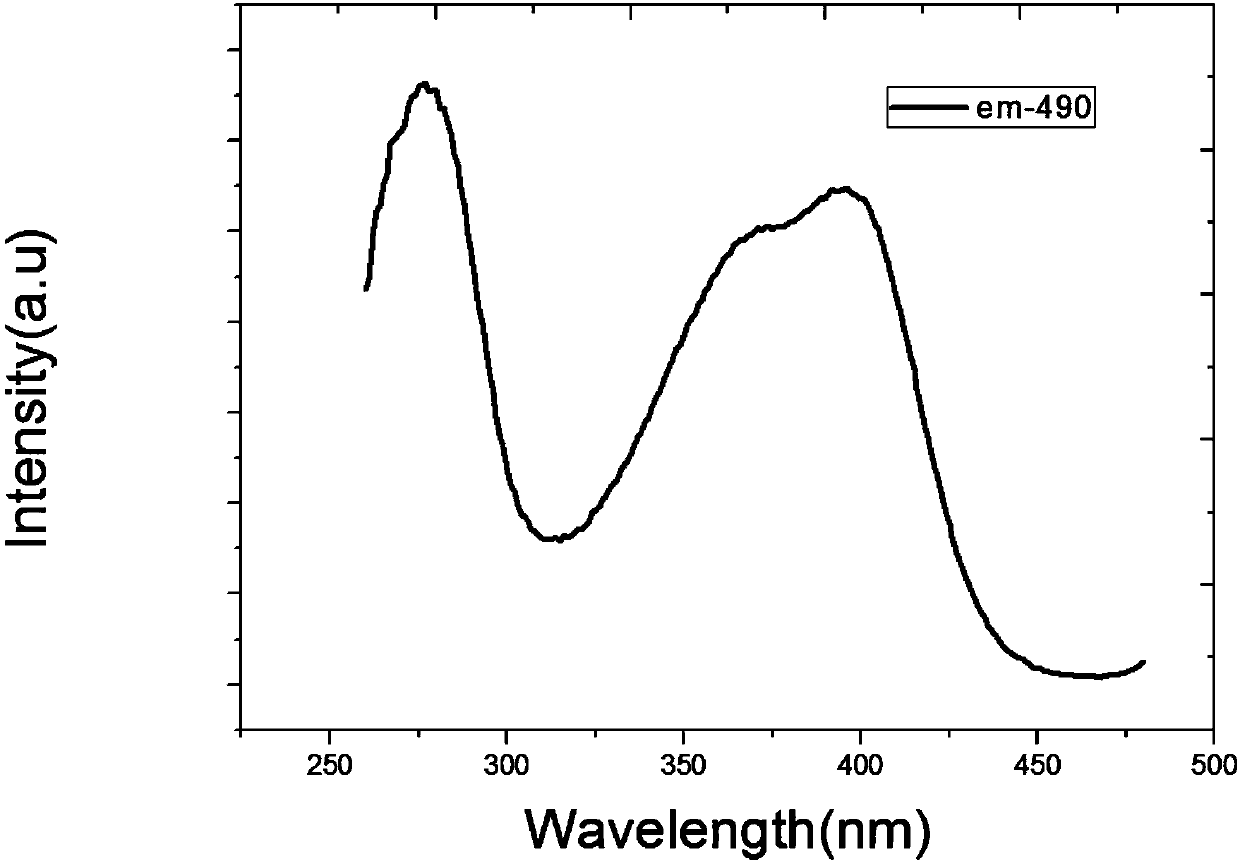

[0048] According to the chemical formula of phosphor (Y 0.98 , Ce 0.02 )ScSi 6 N 4 C, weigh 2.0687g Sc respectively 2 o 3 , 3.3194g Y 2 o 3 , 3.1564g Si 3 N 4 , 0.8918g C, 0.1033g CeO 2 . After fully mixing and grinding, the mixture was placed in a tungsten crucible, under N 2 The sintering is carried out in the atmosphere, the sintering temperature is 1750° C., the sintering time is 10 hours, and it is naturally cooled with room temperature. After the calcined product is crushed, graded, washed, dried and sieved, the composition can be obtained as (Y 0.98 , Ce 0.02 )ScSi 6 N 4 C phosphor. Phase analysis and SrYSi 4 N 7 The crystal structure is similar to ( figure 1 ). Its excitation spectrum (monitored at 490nm) and emission spectrum (excited at 400nm) are as figure 2 and image 3 As shown, it can be seen that the excitation wavelength range covers 260-450 nm, the emission wavelength covers 410-575 nm, and its peak wavelength is located at 474 nm.

Embodiment 2

[0050] According to chemical formula (Y 0.98 , Ce 0.02 )ScSi 6 N 4 The stoichiometric ratio of C, accurately weigh YN (purity 99.9%), ScN (purity 99.9%), Si 3 N 4 (purity 99.9%), SiC (purity 99.9%) and CeN (purity 99.99%) raw materials, and mixed to form a mixed raw material. The mixed raw materials were thoroughly mixed and ground for 30 minutes in a glove box to obtain a mixture. The mixture was raised to 1900°C at a heating rate of 10°C / min, then kept at 1900°C for 10 hours, and the temperature was naturally lowered to obtain a roasted product. After the roasted product is taken out, it is crushed, washed, sieved and dried to obtain the (Y 0.98 , Ce 0.02 )ScSi 6 N 4 C phosphor. The SEM appearance of embodiment 2 is as Figure 4 shown

Embodiment 3

[0052] According to chemical formula (Y 0.94 , Ce 0.06 )ScSi 6 N 4 The stoichiometric ratio of C, accurately weigh YN (purity 99.9%), ScN (purity 99.9%), Si 3 N 4 (purity 99.9%), SiC (purity 99.9%) and CeN (purity 99.99%) raw materials, and mixed to form a mixed raw material. The mixed raw materials were thoroughly mixed and ground for 30 minutes in a glove box to obtain a mixture. The mixture was raised to 1900°C at a heating rate of 10°C / min, then kept at 1900°C for 10 hours, and the temperature was naturally lowered to obtain a roasted product. After the roasted product is taken out, it is crushed, washed, sieved and dried to obtain the (Y 0.94 , Ce 0.06 )ScSi 6 N 4 C phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com