A kind of green fluorescent powder excited by purple light LED and preparation method thereof

A green phosphor and violet light technology, applied in the field of green phosphor, can solve the problems of poor matching and low luminous intensity, and achieve the effect of good matching and high commercial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

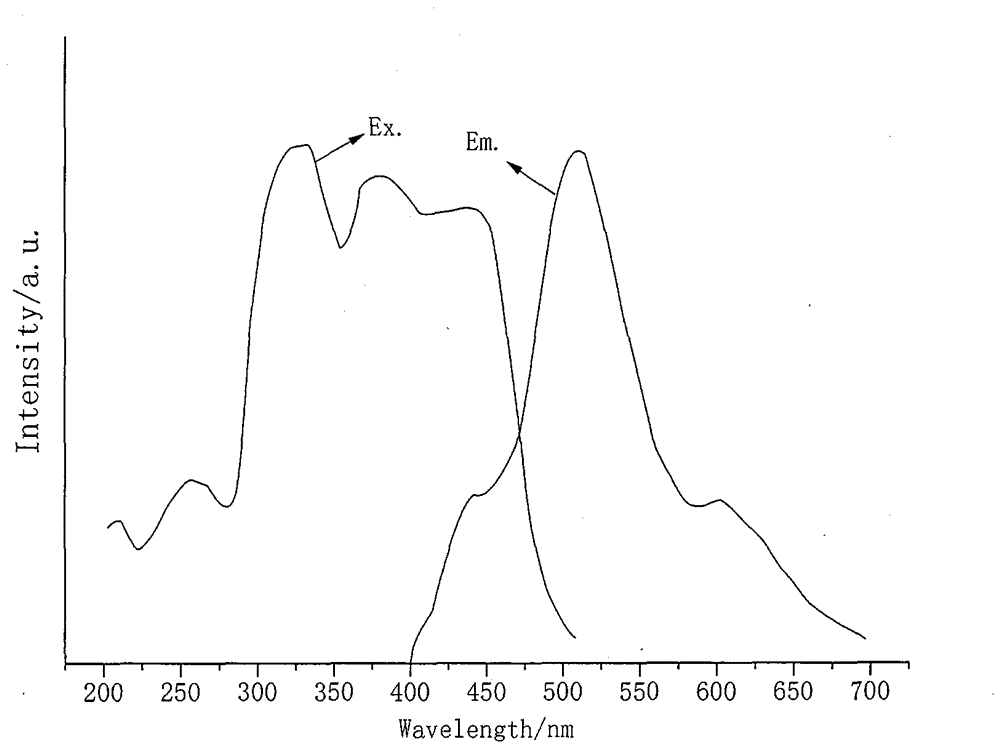

Image

Examples

Embodiment 1

[0019] Weigh 0.95mol CaCO according to the general chemical formula 3 , 1.9 mol MgCO 3 , 8mol SiO 2 , 16mol Al 2 o 3 , 0.025mol Eu 2 o 3 , 0.1mol MnO 2 As a raw material, weigh 0.1% flux AlF of the total mass of the raw material 3 Mix with the raw materials, mix evenly, ball mill for 8 hours, the ball milling speed is 120 rpm, and then calcined in the reducing atmosphere created by activated carbon powder, the temperature is 1150 ° C, the calcining time is 6 hours, and the holding time is 2 hours. Fluorescent classification technology can accurately classify the phosphor powder, that is, get the required Ca 0.95 Mg 1.9 Si 8 al 16 o 43 : 0.05Eu 2+ , 0.1Mn 2+ Phosphor.

Embodiment 2

[0021] Weigh 0.85mol BaCO according to the general chemical formula 3 , 1.85mol MgCO 3 , 8mol SiO 2 , 16mol Al 2 o 3 , 0.075mol Eu 2 o 3 , 0.15mol MnO 2 As a raw material, weigh 0.4% flux NH of the total mass of the raw material 4 Cl is mixed with the raw materials, mixed evenly, ball milled for 9 hours, the ball milling speed is 130 rpm, and then calcined under the reducing atmosphere created by activated carbon powder, the temperature is 1250 ° C, the calcining time is 8 hours, and the holding time is 4 hours. Take out, cool and pulverize, use The swirl classification technology can accurately classify the phosphor powder to obtain the required Ba 0.85 Mg 1.85 Si 8 al 16 o 43 : 0.15Eu 2+ , 0.15Mn 2+ Phosphor.

Embodiment 3

[0023] Weigh 0.80mol SrCO according to the general chemical formula 3 , 1.80mol MgCO 3 , 8mol SiO 2 , 16mol Al 2 o 3 , 0.10mol Eu 2 o 3 , 0.20mol MnO 2 As a raw material, weigh 0.5% flux Li of the total mass of the raw material 2 CO 3 Mix with the raw materials, mix evenly, ball mill for 10 hours, the ball milling speed is 125 rpm, and then calcined under the reducing atmosphere created by activated carbon powder, the temperature is 1300°C, the calcining time is 10h, and the holding time is 2h. Fluorescent classification technology to accurately classify the phosphor powder, that is, to obtain the required Sr 0.80 Mg 1.80 Si 8 al 16 o 43 : 0.20Eu 2+ , 0.20Mn 2+ Phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com