Blue fluorescent powder for violet LED and preparation method thereof, and illumination light source prepared from blue fluorescent powder

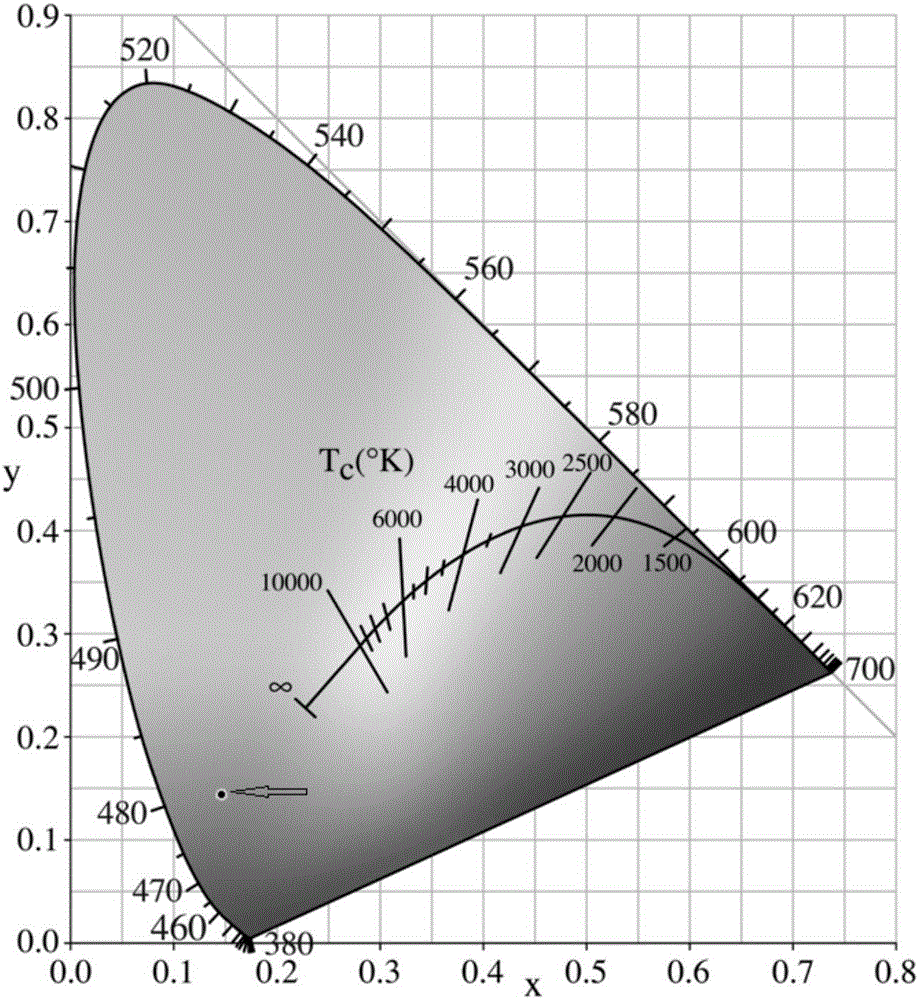

A blue phosphor and violet technology, applied in the field of phosphor materials, can solve the problems of limiting the application of violet LED, low chemical stability, high synthesis temperature, and achieve high commercial application value, high color rendering, and lower reaction temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention provides the preparation method of above-mentioned blue fluorescent powder for violet light LED, and this method comprises the following steps:

[0046] Step 1: According to the chemical structural formula M of the blue phosphor 10 (P 1-3b / 5 N b o 4 ) 6 x 2 :yEu 2+ For the stoichiometric numbers shown, the raw material MCO was weighed separately 3 , ammonium dihydrogen phosphate, MCl 2 and Eu 2 o 3 , mix these raw materials evenly with flux, and put them into a mortar and grind them thoroughly;

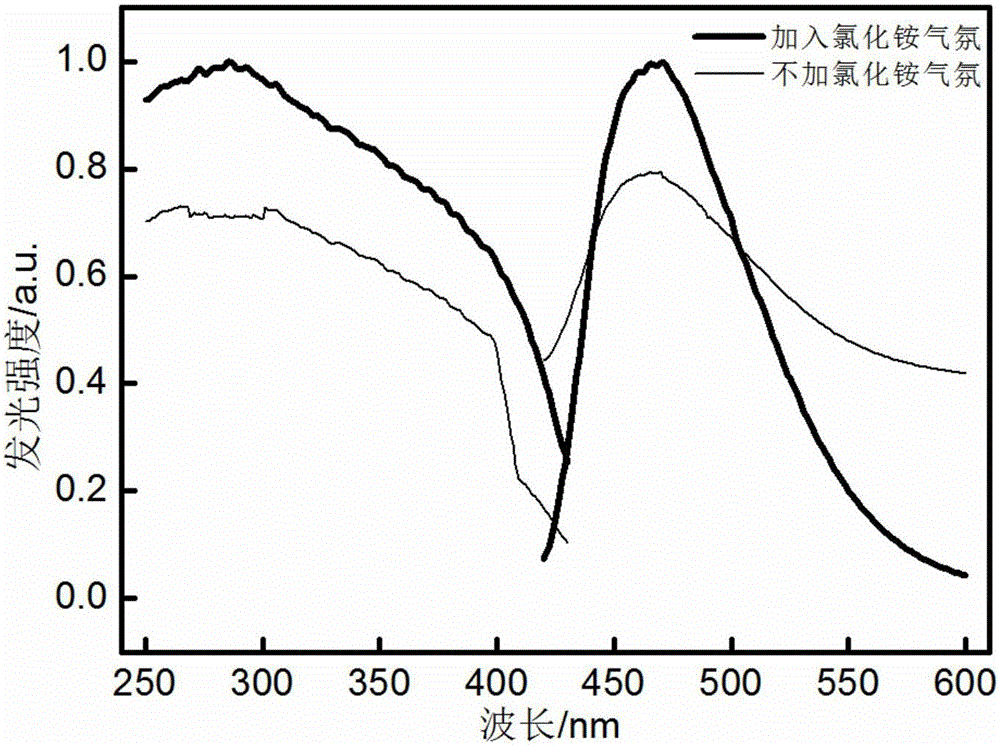

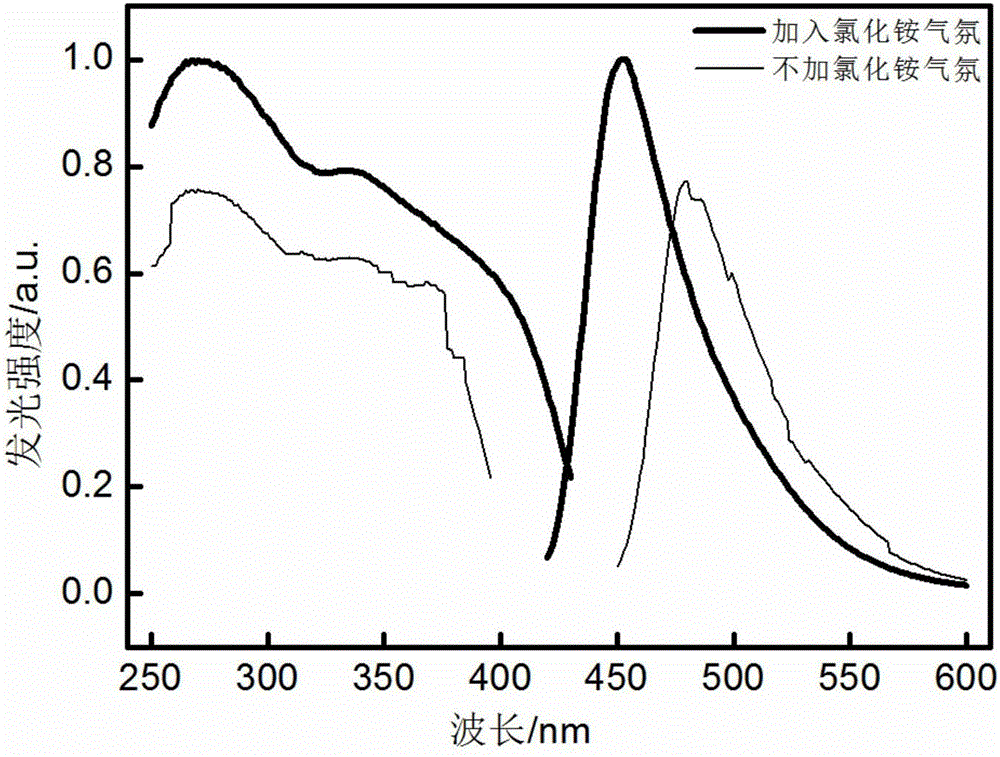

[0047] The second step: put the above-mentioned ground materials into an aluminum crucible, and place a certain amount of ammonium chloride around the crucible, and heat it to volatilize the ammonium chloride to form ammonium chloride in a gas phase state. The calcination synthesis is carried out under the combined action of ammonium chloride atmosphere, the calcination temperature is 1200-1400 DEG C, and the calcination time is 2-5 hours. After...

Embodiment 1

[0053] Weigh 45g ammonium dihydrogen phosphate, 2.3g europium oxide, 17g strontium chloride, 75g strontium carbonate, and weigh 0.6wt% flux BaF of the total mass of raw materials according to the chemical structural formula of the blue fluorescent powder 2 to mix with the ingredients. Mixing the weighed raw material and flux in a mortar for grinding, after grinding for 30 minutes, sieving the ground material through a 200-mesh sieve to obtain the sieved material;

[0054] Put the above-mentioned sieved material into the crucible, then weigh 10wt% ammonium chloride of the total mass of the raw material and place it around the crucible, heat the ammonium chloride to volatilize and form ammonium chloride in the gas phase state, and mix the ammonium chloride with 4% hydrogen reducing atmosphere. The calcination synthesis is carried out under the combined action of ammonium chloride atmosphere, the calcination temperature is 1200°C, and the calcination time is 3h. Then cool down, ...

Embodiment 2

[0060] Weigh 45g ammonium dihydrogen phosphate, 2.3g europium oxide, 17g strontium chloride, 75g strontium carbonate, and weigh 0.6wt% flux BaF of the total mass of raw materials according to the chemical structural formula of the blue fluorescent powder 2 to mix with the ingredients. Mixing the weighed raw material and flux in a mortar for grinding, after grinding for 30 minutes, sieving the ground material through a 200-mesh sieve to obtain the sieved material;

[0061] Put the above-mentioned sun-dried materials into a crucible, and perform calcination under a 4% hydrogen reducing atmosphere, the calcination temperature is 1200°C, and the calcination time is 3h. Then after cooling, pulverizing, sieving, washing with water, washing with alcohol, sieving, and drying, the required Sr 9.8 (P 0.76 N 0.4 o 4 ) 6 Cl 2 :0.2Eu 2+ Phosphor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| spectroscopy | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com