Manufacture method of red quantum dot-based high-color gamut white-light LED lamp bead

A technology of red light quantum dots and LED lamp beads, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as difficult large-scale industrialization, low light conversion efficiency, and complicated processes, so as to reduce difficulty and product defects High efficiency, improved color gamut, and high excitation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

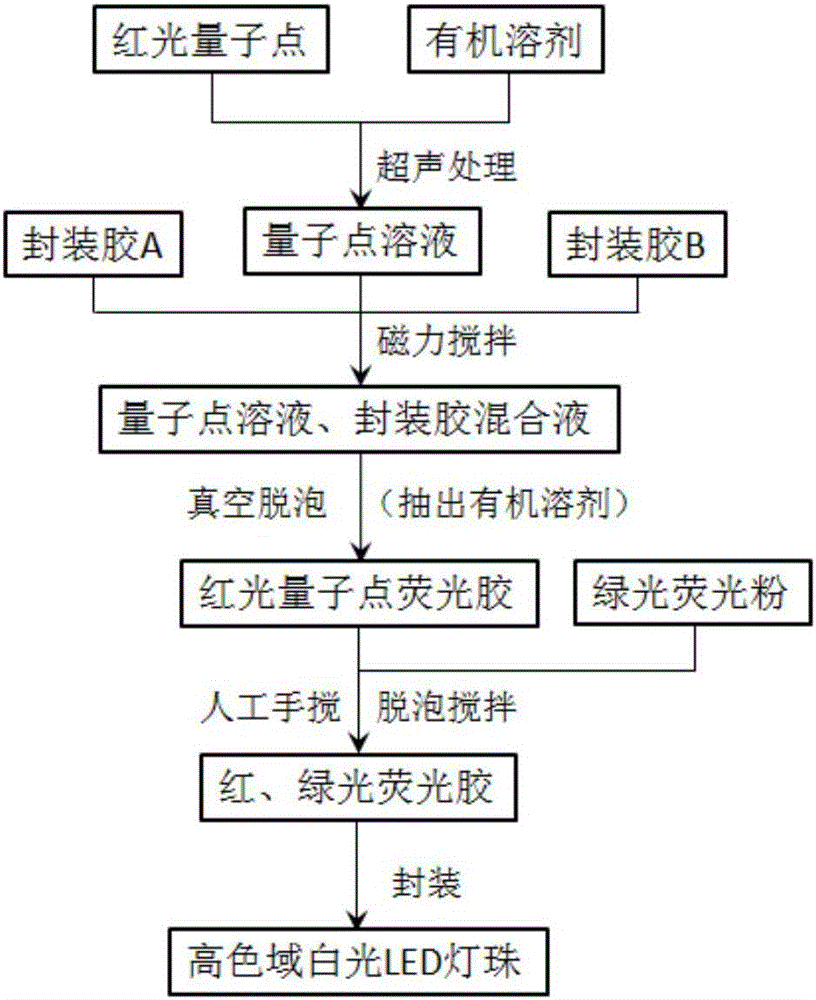

[0032] Embodiment 1 This embodiment discloses a method for manufacturing a high color gamut white LED lamp bead based on red light quantum dots. The specific process steps are as follows: figure 1 Shown:

[0033] 1) Weigh a certain amount of MgTe red light quantum dot phosphor powder with a peak emission wavelength of 630nm (the red light quantum dot phosphor powder is purchased from the market, and its particle size is 5nm). According to the mass ratio of red light quantum dots and organic solvent is 1:1000, add an appropriate amount of organic solvent C to the red light quantum dot phosphor 7 h 8 (toluene).

[0034] 2) The mixed solution obtained in step 1) is placed in an ultrasonic cleaning machine for ultrasonic treatment. Control the water bath temperature of the ultrasonic cleaning machine to 35°C, the ultrasonic frequency to 70KHz, and the ultrasonic treatment time to 40min, so that the red light quantum dot phosphor is completely dissolved in the organic solvent to...

Embodiment 2

[0041] Embodiment 2 This embodiment discloses a method for manufacturing a high color gamut white LED lamp bead based on red light quantum dots. The specific process steps are as follows: figure 1 Shown:

[0042] 1) Weighing a certain amount of GaAs and GaN red light quantum dot phosphors with a peak emission wavelength of 600nm (the red light quantum dot phosphors are purchased from the market, and the particle size is 10nm). According to the mass ratio of red light quantum dots and organic solvent is 1:50, add an appropriate amount of organic solvent CHCl to the red light quantum dot phosphor 3 (chloroform).

[0043] 2) The mixed solution obtained in step 1) is placed in an ultrasonic cleaning machine for ultrasonic treatment. Control the water bath temperature of the ultrasonic cleaning machine to 45°C, the ultrasonic frequency to 15KHz, and the ultrasonic treatment time to 90 minutes, so that the red light quantum dot phosphor is completely dissolved in the organic solve...

Embodiment 3

[0050] Embodiment 3 This embodiment discloses a method for manufacturing a high color gamut white LED lamp bead based on red light quantum dots. The specific process steps are as follows: figure 1 Shown:

[0051] 1) Weigh a certain amount of AgInS red light quantum dot phosphor powder with a peak emission wavelength of 660nm (the red light quantum dot phosphor powder is purchased from the market, and its particle size is 1nm). According to the mass ratio of red light quantum dots and organic solvent is 1:2000, add an appropriate amount of organic solvent C to the red light quantum dot phosphor 6 h 1 2 (cyclohexane).

[0052] 2) The mixed solution obtained in step 1) is placed in an ultrasonic cleaning machine for ultrasonic treatment. Control the water bath temperature of the ultrasonic cleaning machine to 25°C, the ultrasonic frequency to 120KHz, and the ultrasonic treatment time to 10 minutes, so that the red light quantum dot phosphor is completely dissolved in the orga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com