Wire splitting mechanism

A technology of splitting and cored wires, applied in the field of automatic welding of data cables, can solve the problems of scattered cored wires, high defect rate, crossed cores, etc., so as to reduce the production defect rate, save production costs, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

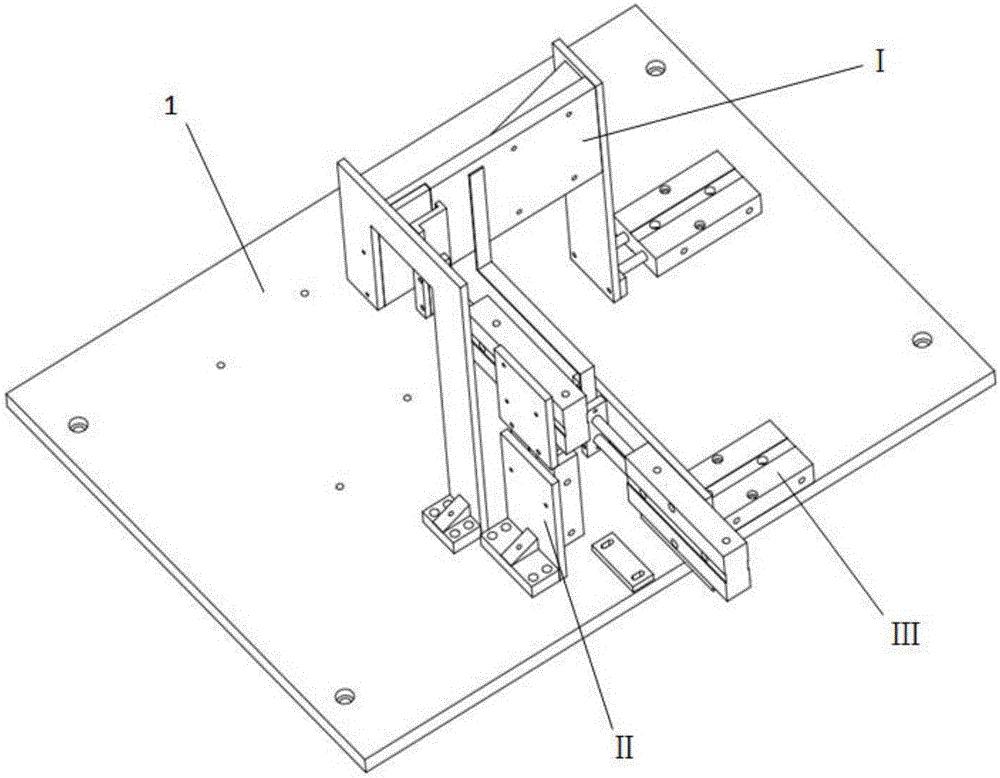

[0027] Such as figure 1 Shown is a wire splitting mechanism provided by a preferred embodiment of the present invention, including a baffle device I, a thread twisting device II, a combing device III and a workbench 1 carrying these devices. The baffle device Ⅰ is closed as a back plate during the process of twisting and combing to provide support for the core wire to facilitate the action of twisting and combing. After the completion of twisting and combing, it opens to form an opening to make the core wire It can be exposed through the opening, so as to facilitate the further processing of the core wire, such as wire loading and clamping. The twisting device II is used to spread out multiple core wires of the data cable, and the combing device III is used to straighten the loosened core wires.

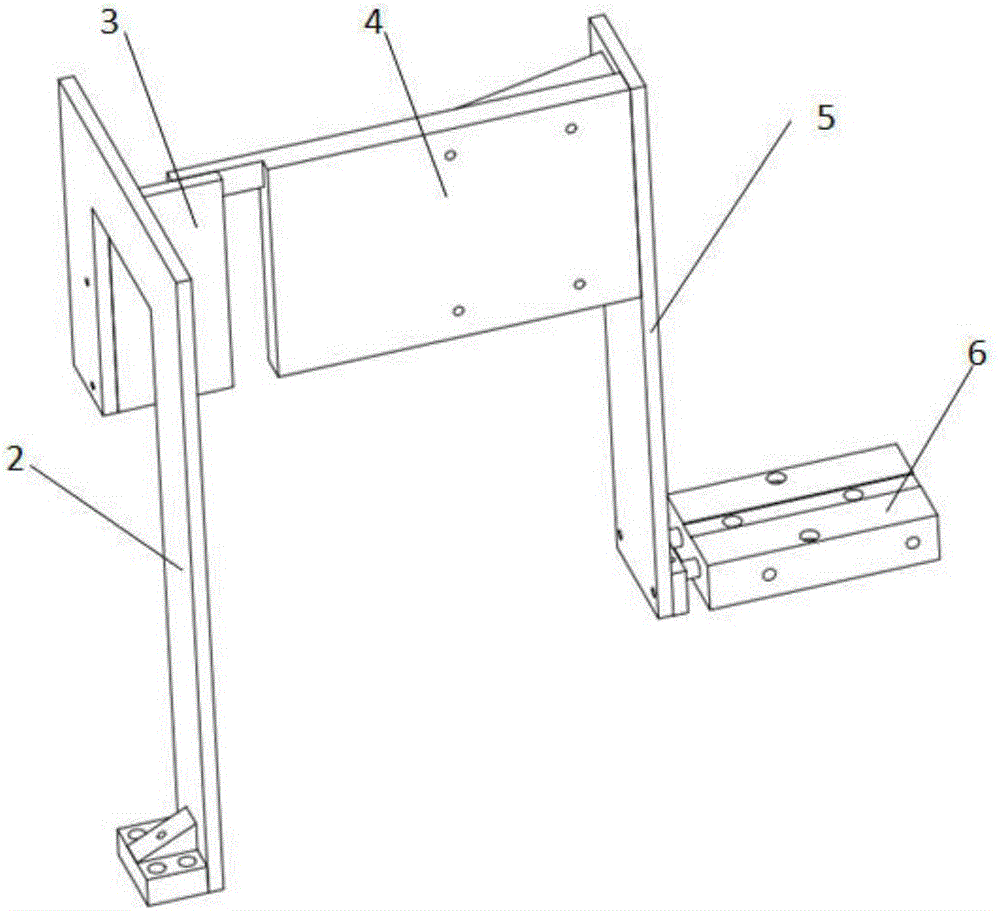

[0028] The baffle device I includes a fixed vertical plate 2, a fixed baffle 3, a movable baffle 4, a movable vertical plate 5 and a first cylinder 6. The fixed vertical plate 2 and...

Embodiment 2

[0035] The thread rubbing board in the thread rubbing device in Embodiment 2 includes a flat plate, on which closely arranged parallel arc-shaped protrusions are arranged, and the center points of every four adjacent arc-shaped protrusions form a square. When the rubbing board rubs the core wires, the core wires can fall into the gaps of the adjacent arc-shaped protrusions, so that the core wires are dispersed. The arc-shaped protrusion can be integrally formed with the flat plate, or fixed on the flat plate in a detachable manner. In a modified embodiment, the arc-shaped protrusions on the flat plate are arranged in strip shapes, each strip has the same length and is equal to the width of the flat plate, and the strip-shaped protrusions are parallel to each other. In another flexible embodiment, the arc-shaped protrusions on the flat plate are also set as strips, but the length of each strip is the same or different, and its length is all less than the width of the flat plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com