Detection method for softness of steel wires

A detection method and technology for steel wire, which is applied in the direction of applying stable tension/pressure to test the strength of the material, which can solve the problems such as the softness and broken wire of the steel wire that cannot be well reflected, so as to reduce the production defect rate and detect The effect of low cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

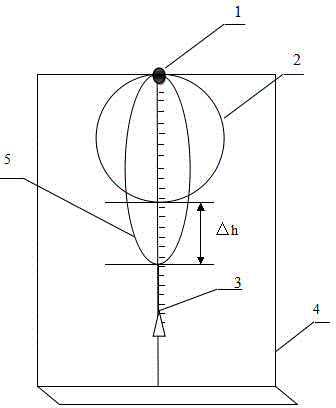

[0018] see figure 1 , a method for detecting the softness of steel wire rods, comprising the steps of:

[0019] 1. select the sample steel wire rod 5 to be tested with a diameter of 0.30 mm, form a circle of 10 cm according to the size of the standard sample ring 2, and fix the seam head on the seam head ring 1 of the test plate (4) with a dial;

[0020] ② Hang a gravity source 3 with a mass M=10g at the lowest point of the steel wire 5 to be tested, so that the steel wire 5 to be tested is stretched naturally, and record the elongation of the steel wire 5 to be tested △h=18mm;

[0021] ③According to the formula R=△h / M, calculate the value of softness, where R is the softness, and substituting the data into the formula to calculate the softness R is 1.8mm / g.

Embodiment 2

[0023] A method for detecting the softness of steel wire rods, comprising the steps of:

[0024] ① select the sample steel wire rod 5 to be tested with a diameter of 0.35 mm, circle it into a circle of 10 cm according to the size of the standard sample ring 2, and fix the seam head on the seam head ring 1 of the test plate 4 with a dial;

[0025] ② Hang a gravity source 3 with a mass M=10g at the lowest point of the steel wire 5 to be tested, so that the steel wire 5 to be tested is stretched naturally, and record the elongation of the steel wire 5 to be tested △h=9mm;

[0026] ③According to the formula R=△h / M, calculate the value of softness, where R is the softness, and substituting the data into the formula to calculate the softness R is 0.9mm / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com