Method for melting nickel alloy by selective ink instead of dry film

A selective, nickel-gold chemical technology, applied in the direction of removing conductive materials by chemical/electrolytic methods, can solve the problems of cumbersome production process, unfavorable market development, long production cycle, etc., to achieve the protection of ecological environment, The effect of reducing production defect rate and saving ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

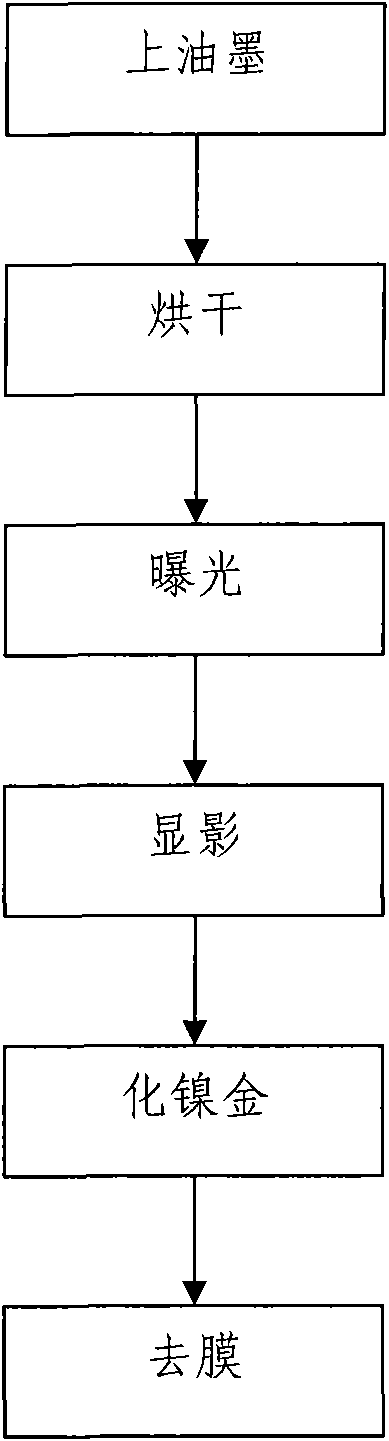

[0015] figure 1 It is a flow chart of the method of selective ink instead of dry film for nickel and gold of the present invention. Such as figure 1 As shown, the selective ink of the present invention replaces the dry film method for nickel and gold, including the following steps:

[0016] 1) Inking: Use a screen printer to coat the chemically resistant nickel and gold ink on the newly cleaned circuit board that does not require nickel and gold to form a wet film, exposing the nickel and gold areas. The thickness of the wet film is 20+5μm, and the cost can be reduced to 1 / 5 of the original by replacing the dry film with a wet film, and the combination effect of the wet film and the board surface is better than that of the dry film and the board surface, effectively preventing defects such as penetration Phenomenon, reduce the defective rate of production, guarantee the quality, and have strong market competitiveness;

[0017] 2) Drying: Put the circuit board coated with chemical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com