Visual recognition-based usb line splitting and arranging mechanism

A visual identification and line separation technology, applied in the direction of line/collector parts, electrical components, circuits, etc., can solve the problems of high error rate of manual operation wiring, toxic gas, human injury, etc., to reduce the production defect rate , low cost, and the effect of avoiding harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

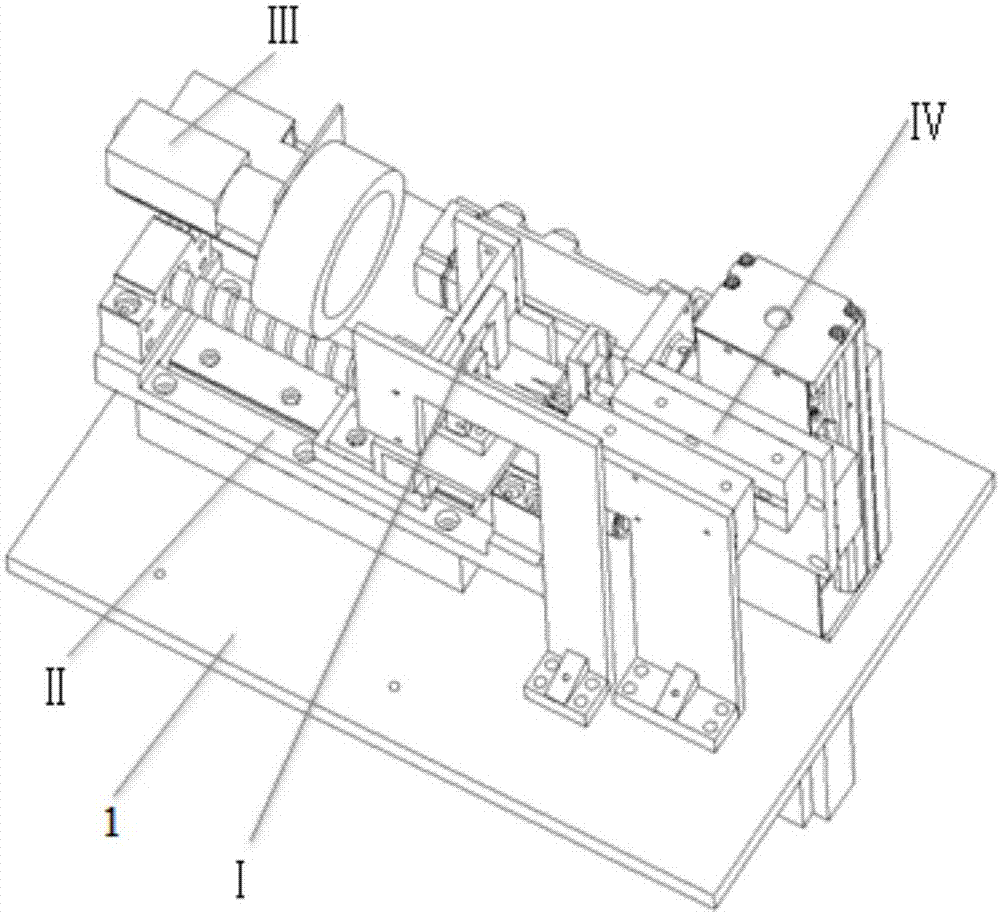

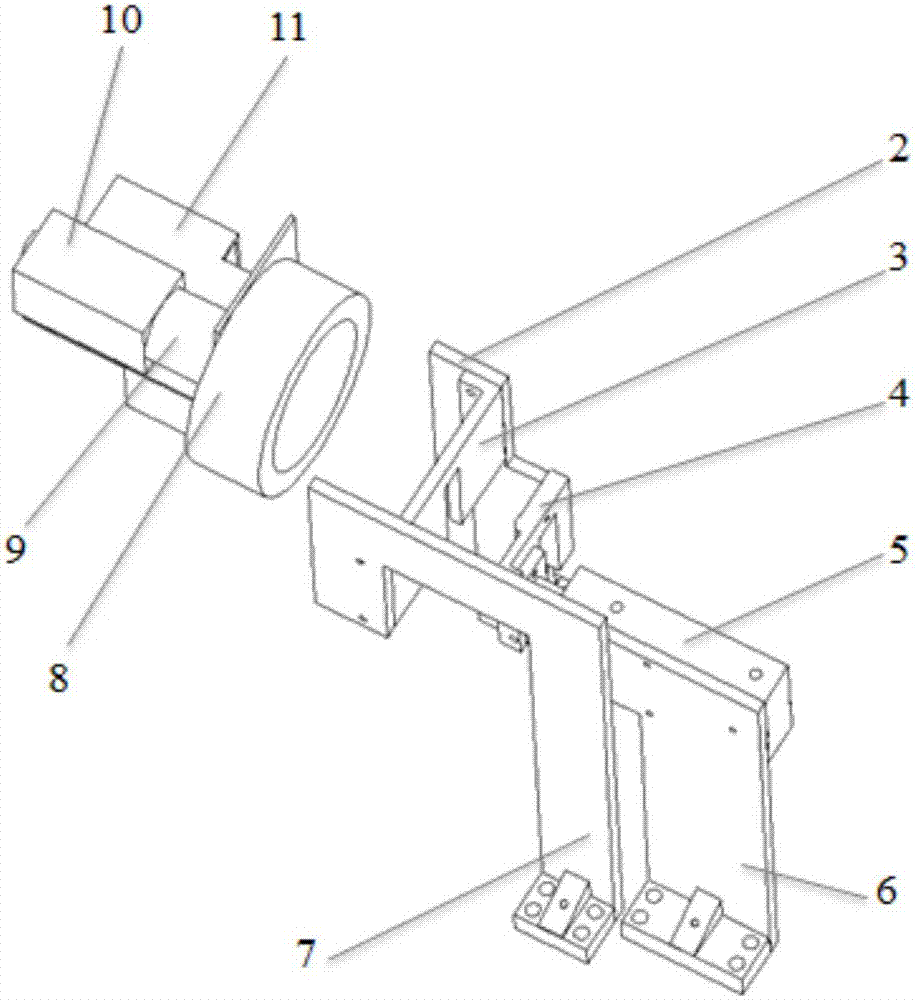

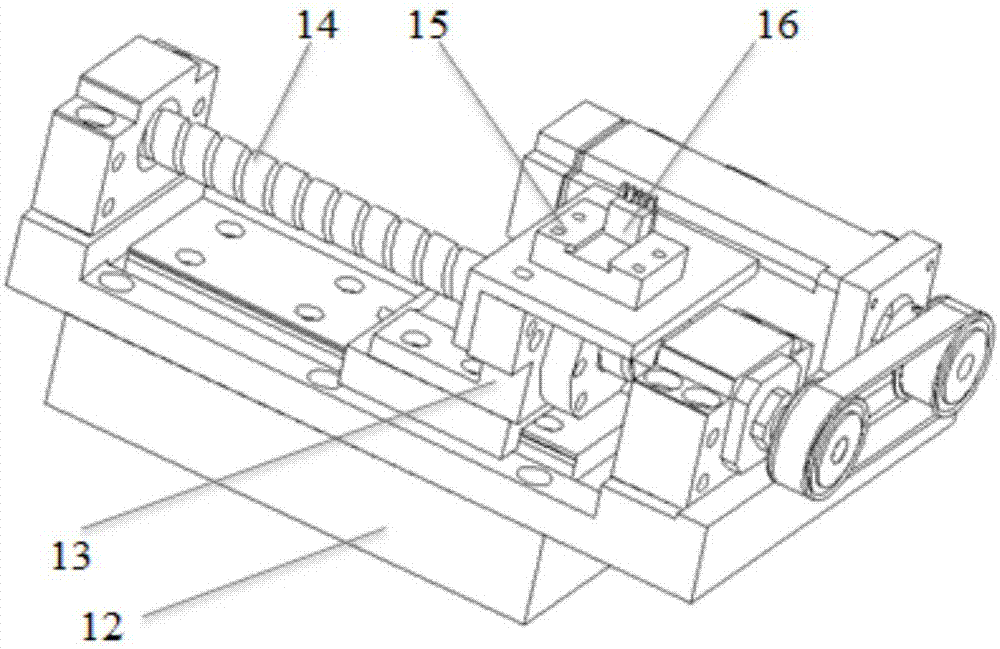

[0026] refer to Figure 1 to Figure 5 , in one embodiment, a visual identification-based USB line splitting and arranging mechanism, including a workbench 1 and a line splitting device I installed on the workbench 1, a wire clip carrying movement device II, a visual inspection Device III and the wire-loading and clamping device IV, the wire-distributing device I is used to disperse and position the USB wires, the wire clamp is equipped with a moving device II for carrying a wire-receiving clamp to realize its movement, and the visual inspection device III is used to Collect the color and position information of the USB cable by taking pictures so as to control the moving device II and the wire clamping device IV of the wire clip. Dial in the take-up c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com