Ultraviolet light and multi-quantum dot combined high-gamut white light implementation mode

A red light quantum dot and multi-quantum technology, applied in the field of white light LED backlight, can solve the problems of difficult large-scale industrialization, difficult curing of packaging glue, low light conversion efficiency, etc., to reduce difficulty and product defect rate, improve quality, The effect of increasing the color gamut value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

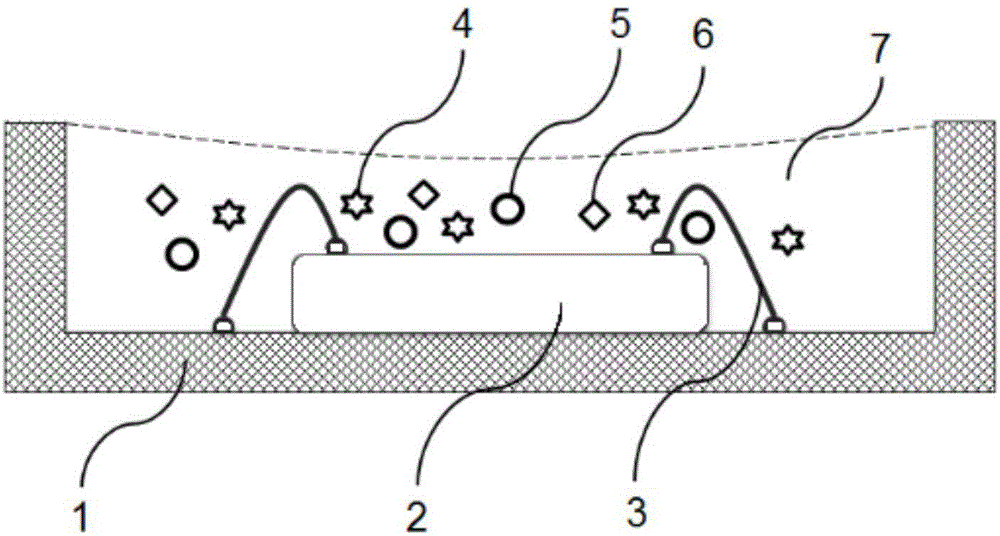

[0034] This embodiment provides a high color gamut white light realization method combining ultraviolet light and multi-quantum dots, including the following steps:

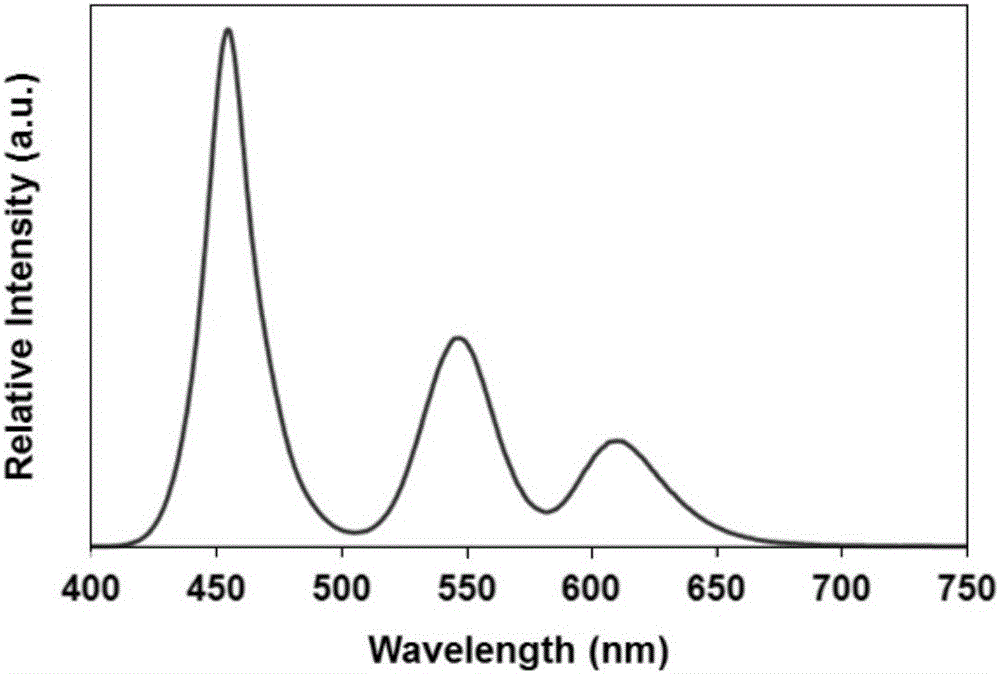

[0035] a. Add 50 parts by weight of organic solvent n-hexane to 1 part by weight of BaS red light quantum dot phosphor powder with a peak emission wavelength of 600nm to obtain a red light quantum dot solution; to AgInS with a peak emission wavelength of 510nm 2 Add 50 parts by weight of an organic solvent cyclohexane to the green light quantum dot fluorescent powder to obtain a green light quantum dot solution; add 50 parts by weight of an organic solvent n-octane to 1 part by weight of NaCl blue light quantum dot fluorescent powder with a luminous peak wavelength of 430 nm to obtain Blue light quantum dot solution; the red light quantum dot fluorescent powder, green light quantum dot fluorescent powder and blue light quantum dot fluorescent powder are all commercially available fluorescent powder, the particle s...

Embodiment 2

[0043] This embodiment provides a high color gamut white light realization method combining ultraviolet light and multi-quantum dots, including the following steps:

[0044] a. To 1 part by weight of Fe whose emission peak wavelength is 660nm 2 o 3 、In 2 o 3 2000 parts by weight of organic solvent toluene are added to the InAs red light quantum dot phosphor powder to obtain a red light quantum dot solution; 1500 parts by weight of organic solvent dichloromethane is added to InN and InP green light quantum dot phosphor powder of 550nm luminescence peak wavelength in 1 weight part , to obtain a green light quantum dot solution; to 1 weight part of CdS, CdSe blue light quantum dot fluorescent powder with a luminous peak wavelength of 480nm, add 1000 parts by weight of organic solvent chloroform to obtain a blue light quantum dot solution; the red light quantum dot fluorescent powder, Both the green light quantum dot phosphor and the blue light quantum dot phosphor are commerci...

Embodiment 3

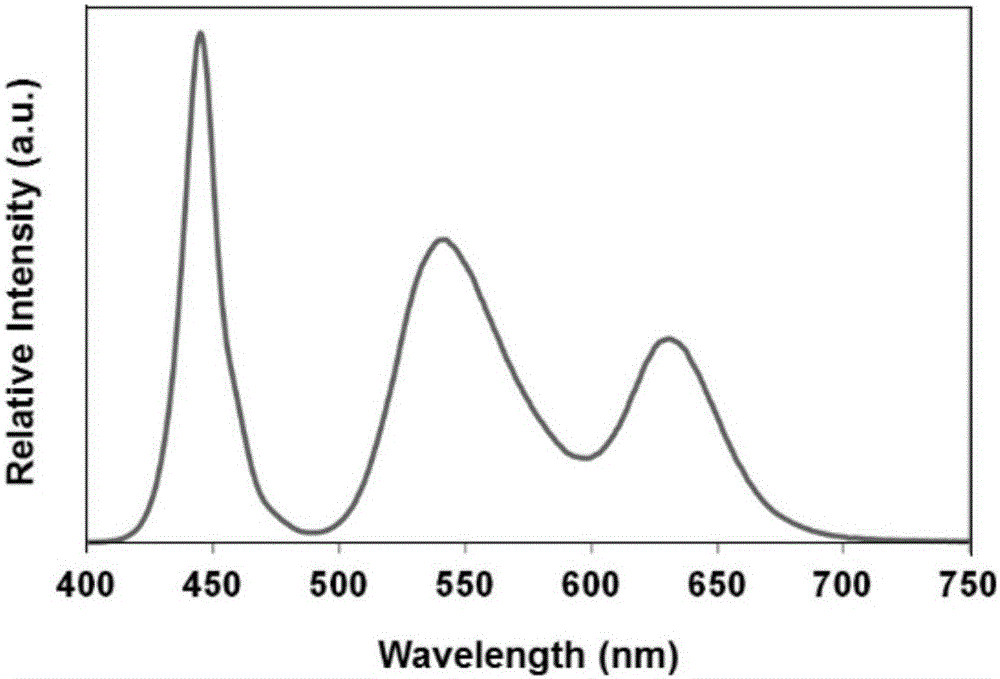

[0051] This embodiment provides a high color gamut white light realization method combining ultraviolet light and multi-quantum dots, including the following steps:

[0052] a. Add 200 parts by weight of organic solvent pyridine to 1 part by weight of CdTe, ZnS, and ZnSe red light quantum dot phosphors with a peak emission wavelength of 620nm to obtain a red light quantum dot solution; Add 500 parts by weight of organic solvent dichloromethane to the green light quantum dot phosphor powder to obtain a green light quantum dot solution; add 100 parts by weight of organic solvent n-hexane to 1 part by weight of GaN and GaS blue light quantum dot phosphor powder with a peak emission wavelength of 446nm, Obtain blue light quantum dot solution; described red light quantum dot fluorescent powder, green light quantum dot fluorescent powder and blue light quantum dot fluorescent powder are commercially available fluorescent powder, wherein, red light quantum dot fluorescent powder parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com