Tailor-welded type aluminum alloy module tray and battery pack

A technology of aluminum alloy molds and trays, which is applied in the direction of batteries, battery pack parts, circuits, etc., can solve problems such as difficult to meet customer requirements, unfavorable large-scale production, and uneven surface, so as to save internal space, light weight, and application broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

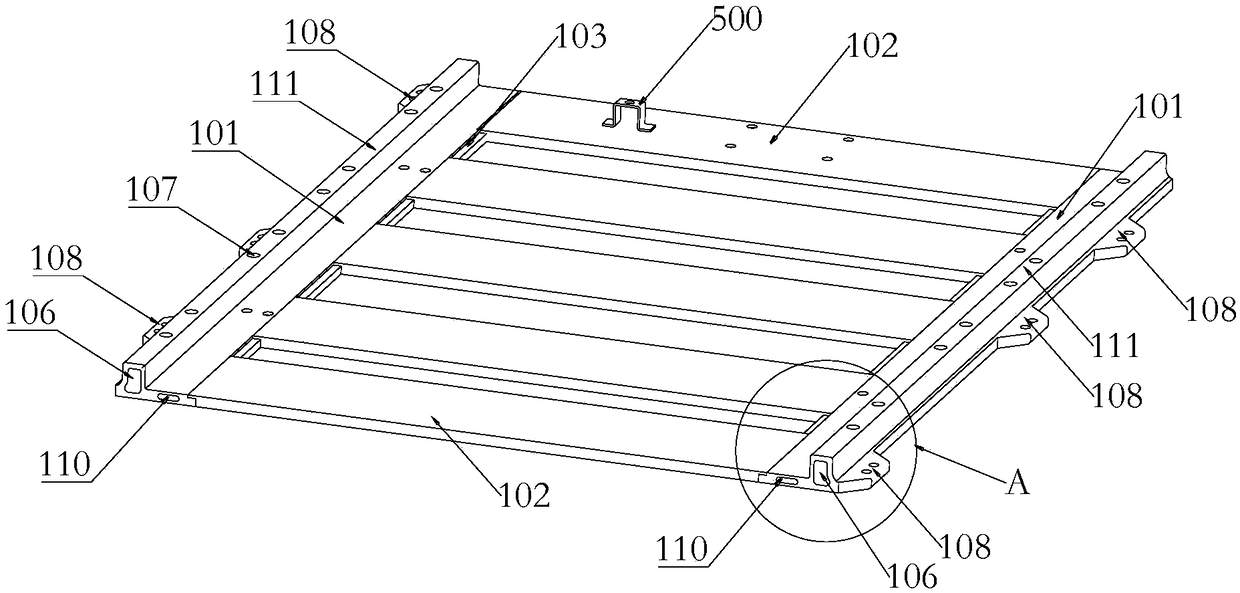

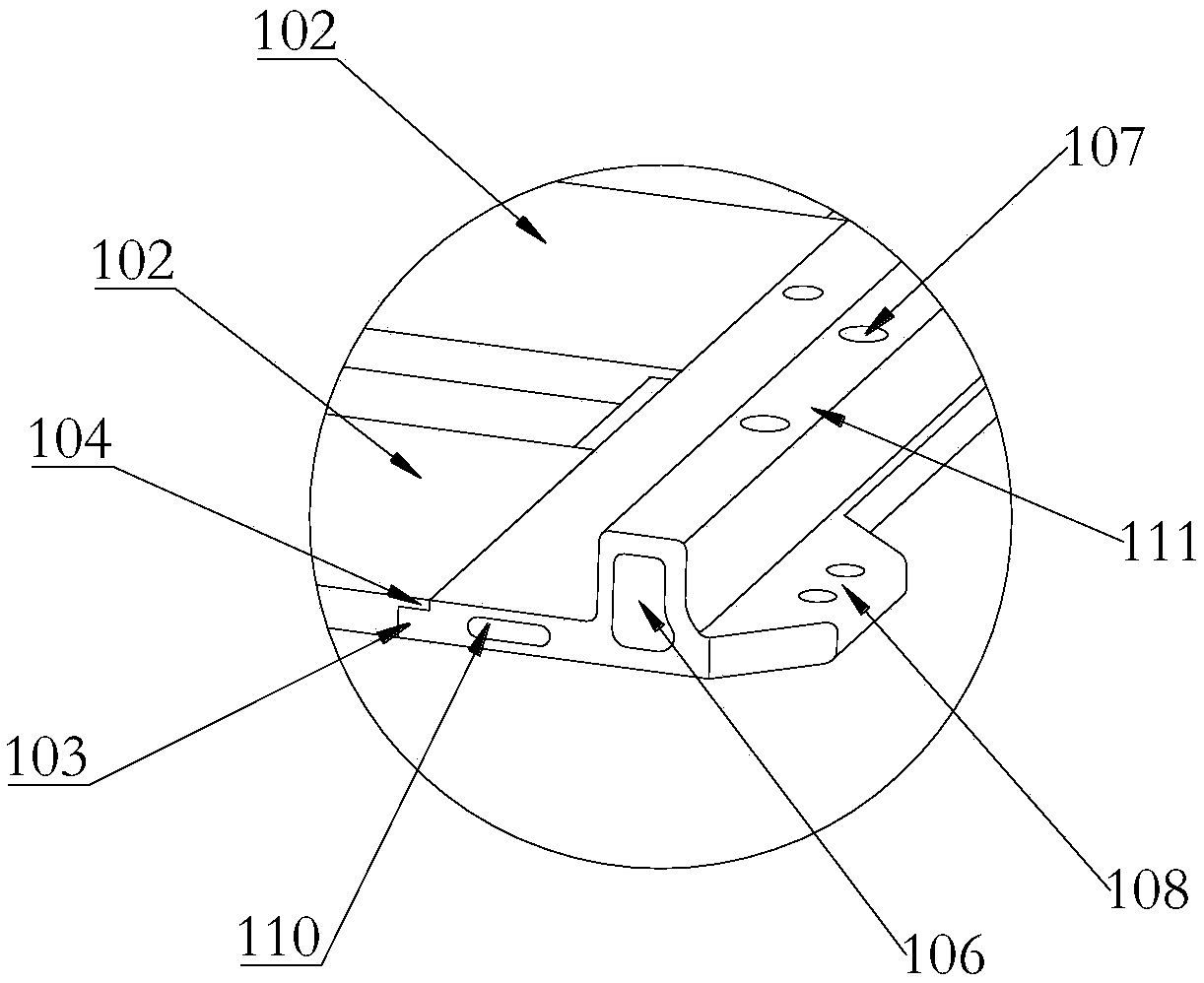

[0044] Such as Figure 1-Figure 9 As shown, a tailor-welded aluminum alloy module tray in this embodiment includes a first tray 100, and the first tray 100 includes two first fixed beams 101 and several first beams 102, and the two first A fixed beam 101 is arranged in parallel and is respectively connected to the battery box 300 . Both ends of the first beam 102 are respectively welded to the two first fixed beams 101 . The first pallet can be conveniently adjusted according to actual needs by adjusting the number of first beams or adjusting the gap between the first beams or adjusting the length of the first beams by tailor-welding several first beams and the first fixed beam In order to meet the needs of different projects, the application is more extensive. At the same time, the first beams are not continuous, but independent of each other. There are gaps between the first beams, which can reduce part of the weight of the first pallet and increase the energy density. The ...

Embodiment 2

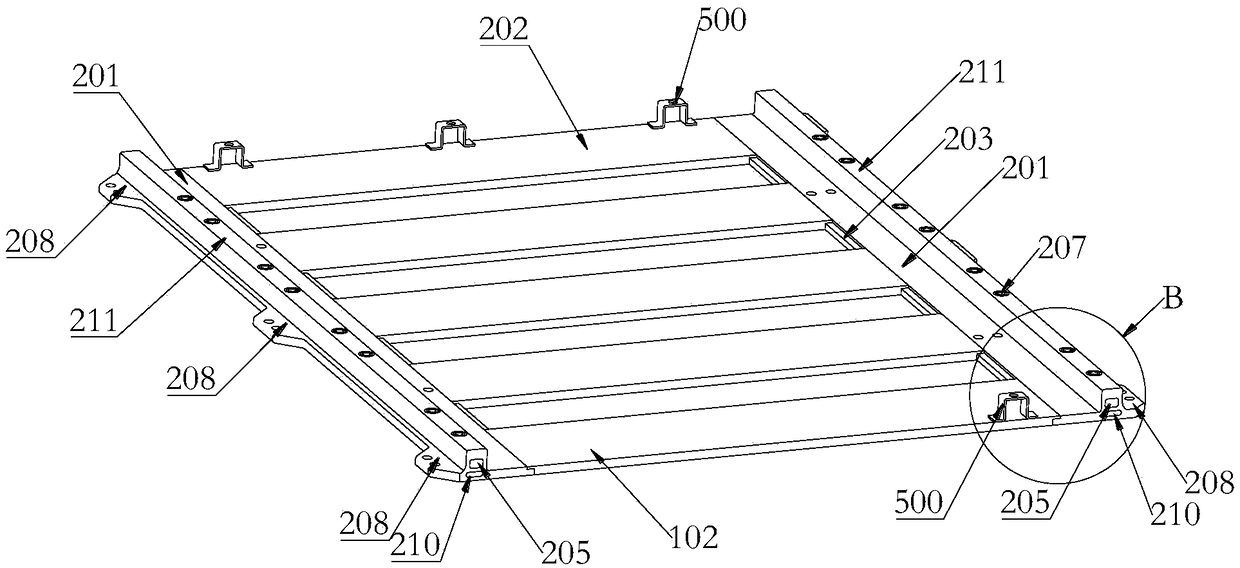

[0053] In fact, a tailor-welded aluminum alloy module tray in this embodiment includes a second tray 200. The first tray 100 and the second tray 200 in this embodiment are generally similar in structure, but the specific details are different.

[0054] Such as Figure 1-Figure 9 As shown, in this embodiment, the second tray 200 includes two second fixed beams 201 and several second beams 202, the two second fixed beams 201 are arranged in parallel and connected to the battery box 300 respectively , two ends of the second beam 202 are respectively welded to the two second fixed beams 201 . The second pallet can be conveniently adjusted according to actual needs by adjusting the number of second beams or the gap between the second beams or the length of the second beams by adjusting the number of second beams and the second fixed beam. In order to meet the needs of different projects, the application is more extensive. At the same time, the second beams are not continuous, but ...

Embodiment 3

[0066] Such as Figure 10 As shown, a battery pack in this embodiment includes a battery case 300, a battery module 400 and the module tray, the module tray is installed in the battery case 300, and the battery module 400 are installed on the bottom beam of the battery box and the module tray respectively. The battery box 300 is provided with a column 301, and the first connecting plate 108 on the first tray 100 of this embodiment or the second connecting plate 208 on the second tray 200 respectively passes through the first mounting hole 109 or the second mounting hole 109. The hole 209 is connected to the upper end of the column 301, and the lower end of the column is connected to the battery box.

[0067] In the battery pack of this embodiment, a two-layer module tray is arranged inside the battery box, and the two-layer module tray plays a role in supporting the two-layer battery module or other components in the battery pack in the entire battery pack, and can make full ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com