Integral car body frame

An integral, skeleton technology, applied in the direction of vehicle components, superstructure, superstructure sub-assembly, etc., can solve the problems of too many parts, accumulated errors in assembly accuracy, complex welding process, etc., to reduce fuel consumption, reduce parts, reduce Effects of molds and fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

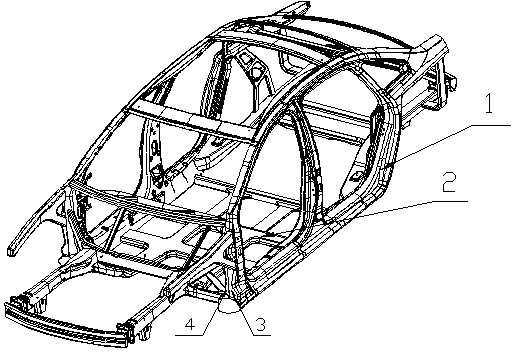

[0009] Such as figure 1 As shown, an integral body frame is composed of an integral side frame 1 and a lower car body frame 2 at the bottom of the integral side frame 1, and the integral side frame includes an integral side frame outer panel 3 And the integral side frame inner panel 4, and the integral side frame outer panel 3 and the integral side frame 4 inner panel are all welded by laser full welding, and the lower car body middle frame 2 is integrally formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com