Test method based on forming limit diagrams for plate hydroforming

A test method and hydroforming technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to judge the forming limit, unable to obtain the forming limit map, not suitable for liquid filling forming, etc., to reduce the friction coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

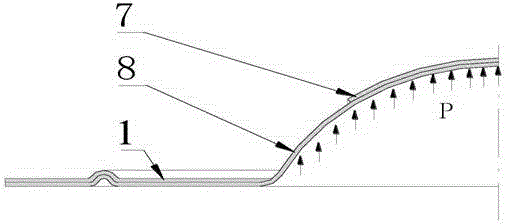

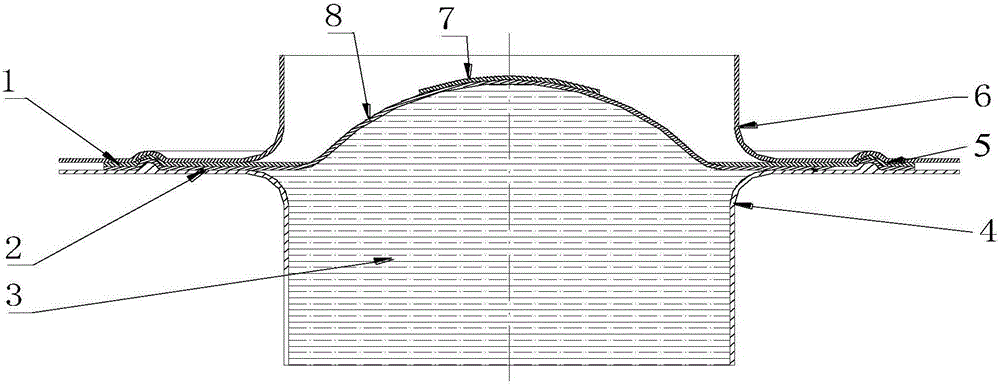

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] 1. The test board 7, 1 auxiliary board 1, 2 auxiliary board 5 and laminated auxiliary board 7 are stacked together as the test board.

[0022] 2. Through hydraulic bulging, the test piece reaches a state of concentrated instability.

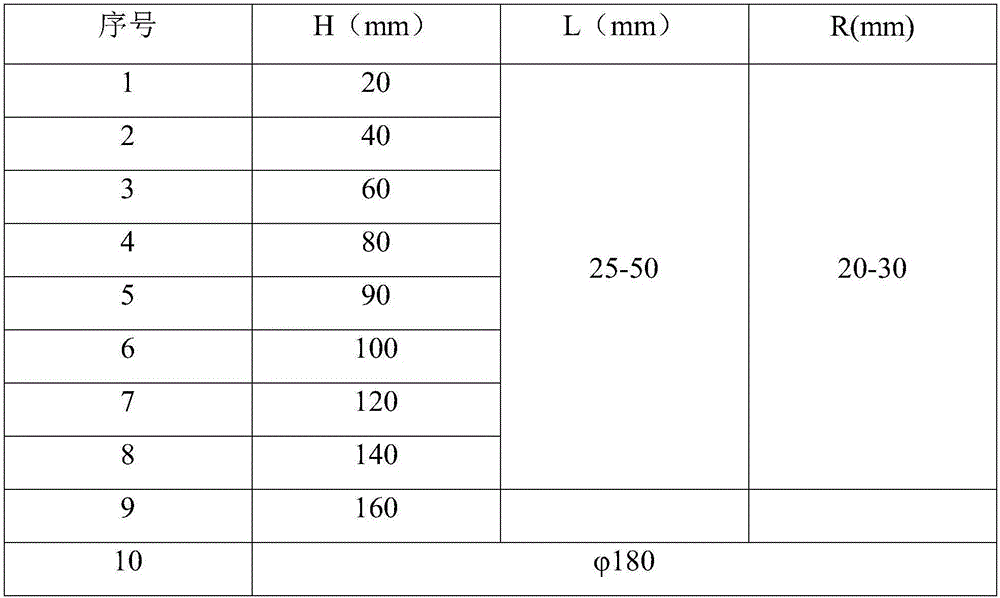

[0023] 3. Obtain the principal strain and secondary strain at the rupture point by testing test pieces with different thicknesses.

[0024] 4. Fit the forming limit curve F of tension-tension and tension-compression state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com