Interior structure of square socket

A technology of internal structure and socket, applied in the direction of contact parts, base/housing, fixed/insulated contact components, etc., can solve problems such as uncompact structure design, safety accidents, troublesome assembly, etc., to save assembly labor time and ensure mechanical structure safety , The effect of saving wire materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

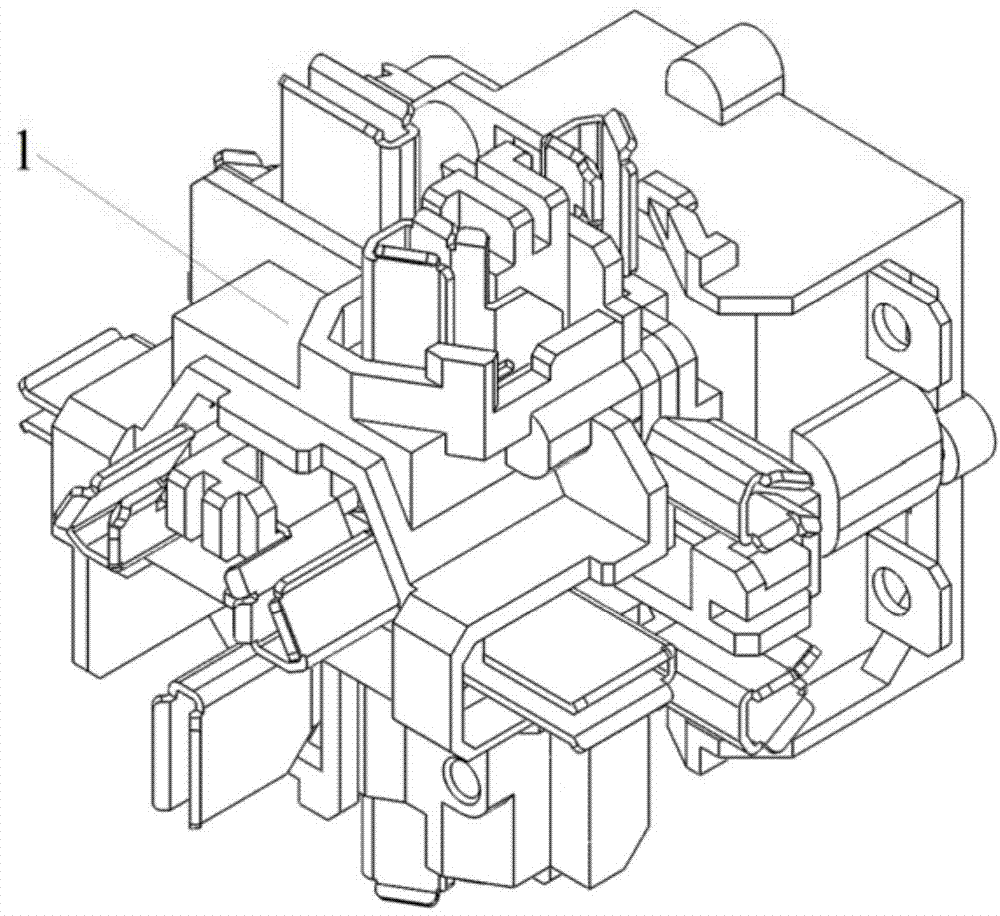

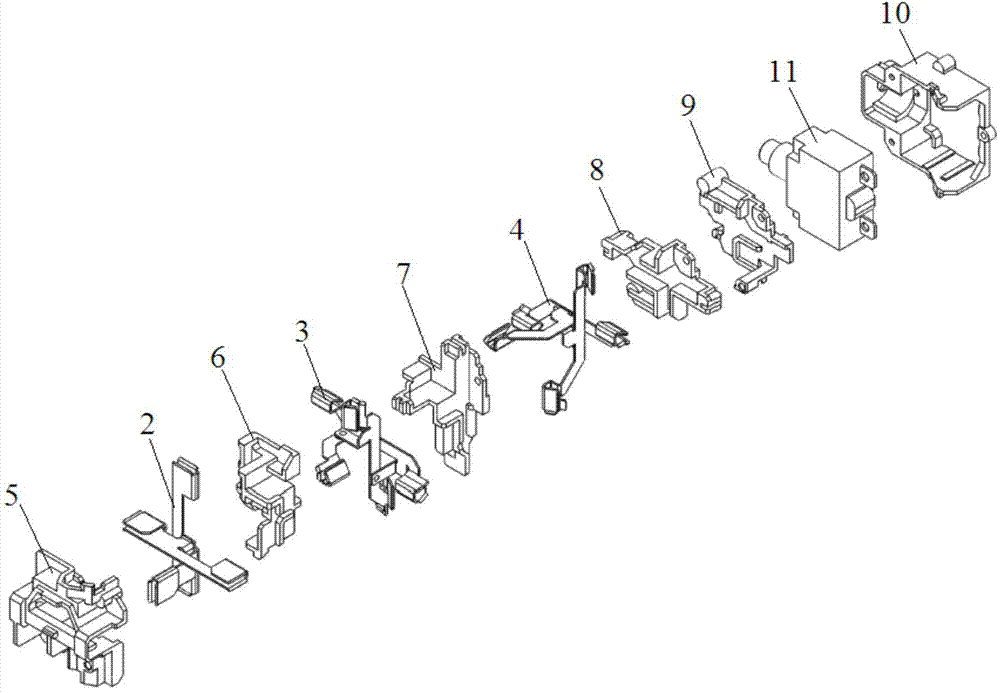

[0044] Such as Figure 1-Figure 2 As shown, a square socket internal structure 1 is arranged in a square socket housing, the square socket is a regular hexahedron structure, at least one surface of the square socket is provided with a socket hole, and the square socket internal structure 1 includes multiple 5 to 8 plastic connectors and three groups of bent metal groups, the three groups of bent metal groups are relatively independent, connected at the center of the socket through plastic connectors to form a whole, the whole can make the zero line and live wire cross distributed , the socket holes that maintain the same polarity are always on the same side of the socket on each side. The plastic connector plays an insulating role, and the structure of the plastic connector matches each bent metal group and fills between each metal group.

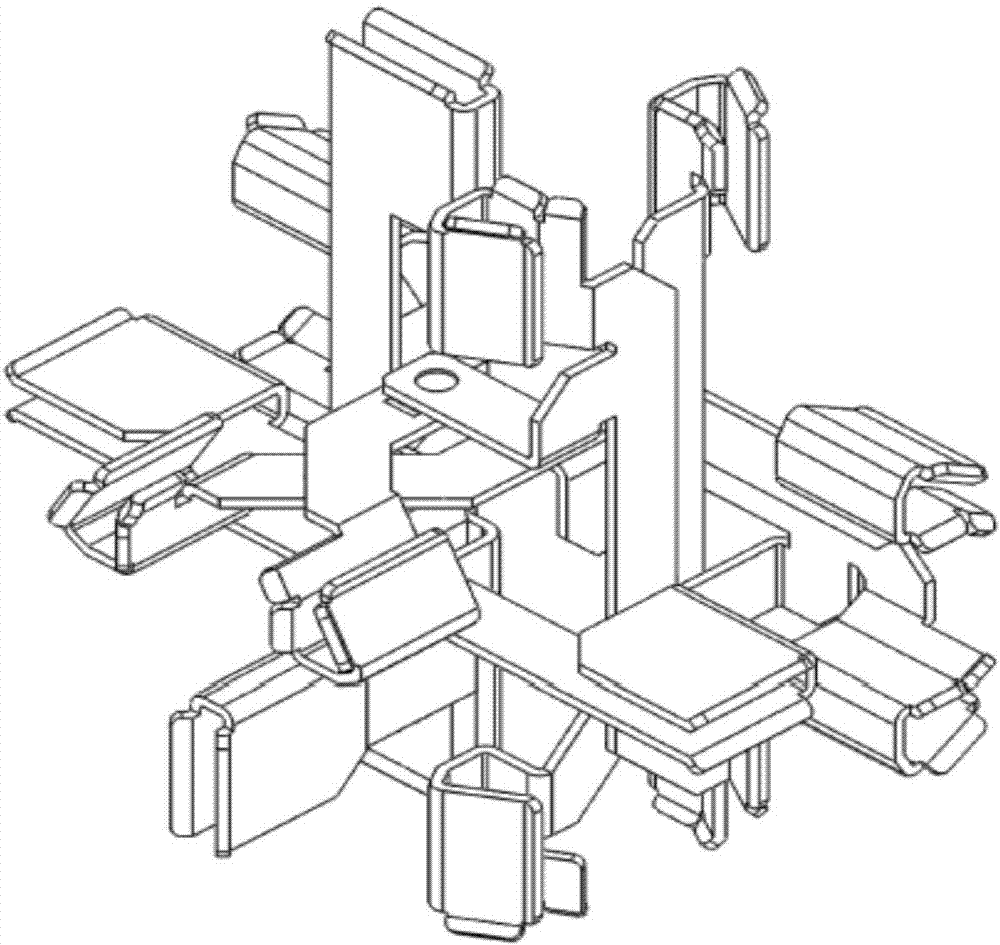

[0045] Such as image 3 As shown, the bent metal parts include a ground wire metal group 2, a neutral wire metal group 3 and a live wire...

Embodiment 2

[0054] Such as Figure 11-Figure 12 As shown, in this embodiment, each metal bending group includes only two metal sheets perpendicular to each other, that is, the first ground wire metal sheet 201, the first neutral wire metal sheet 301, and the first live wire metal sheet in Embodiment 1. All the pieces 401 are removed, and there is a space in the square socket for placing related functional components, such as: USB charger, wireless module, remote control switch and so on. All the other are with embodiment 1.

Embodiment 3

[0056] Reference as Figure 1-Figure 2 As shown, in this embodiment, each metal bending group includes three metal sheets arranged perpendicular to each other, so that all six faces of the square socket can be used as sockets. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com