Combined blow-molding tray

A combination and tray technology, applied in rigid containers, containers, packaging, etc., can solve problems such as loosening of bolt holes and screw rods, complex manufacturing process of inserting rod devices, and damage to tray structures, so as to save transportation space and facilitate assembly and disassembly. The solution process is simple and fast, and the effect of manufacturing low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

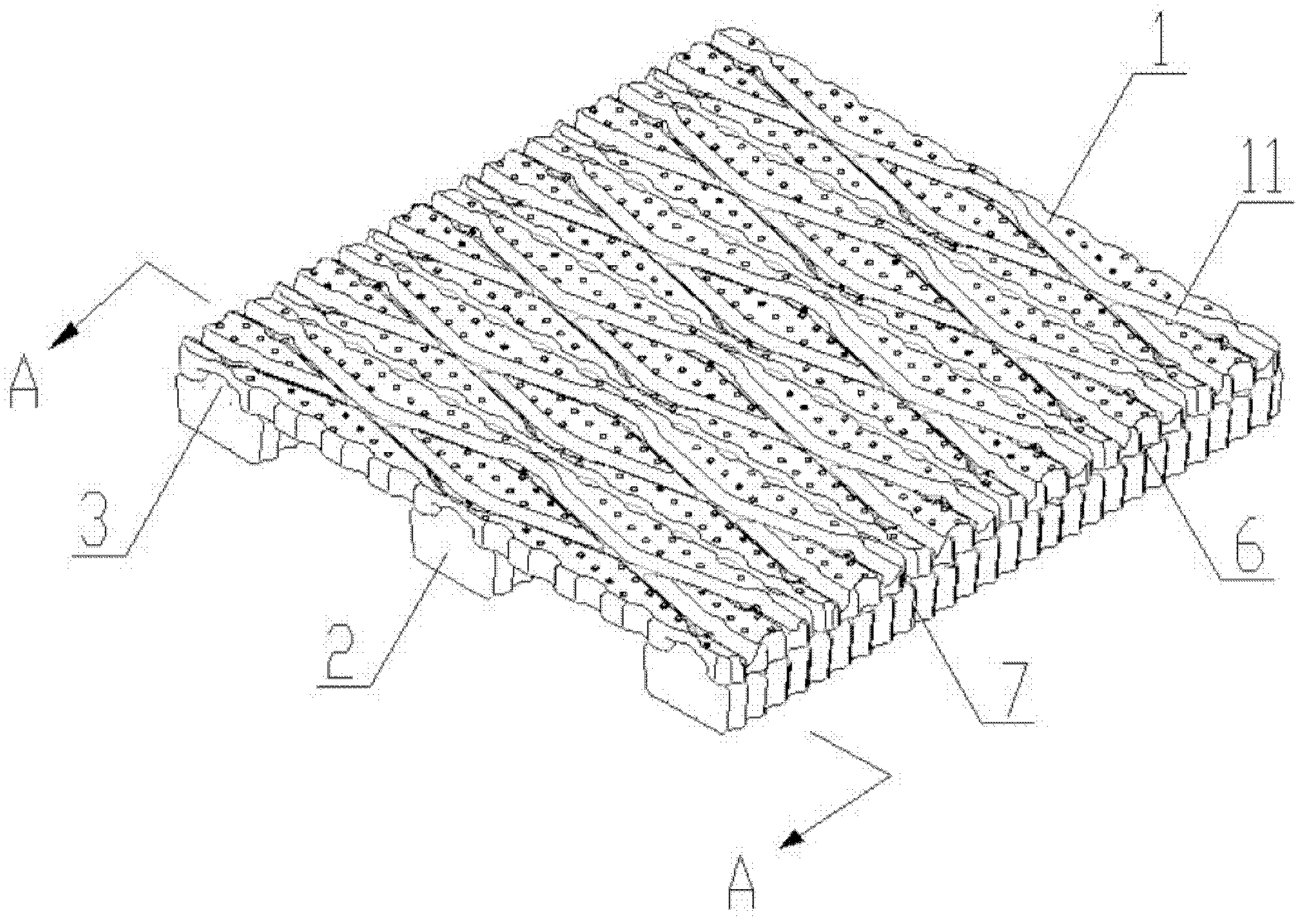

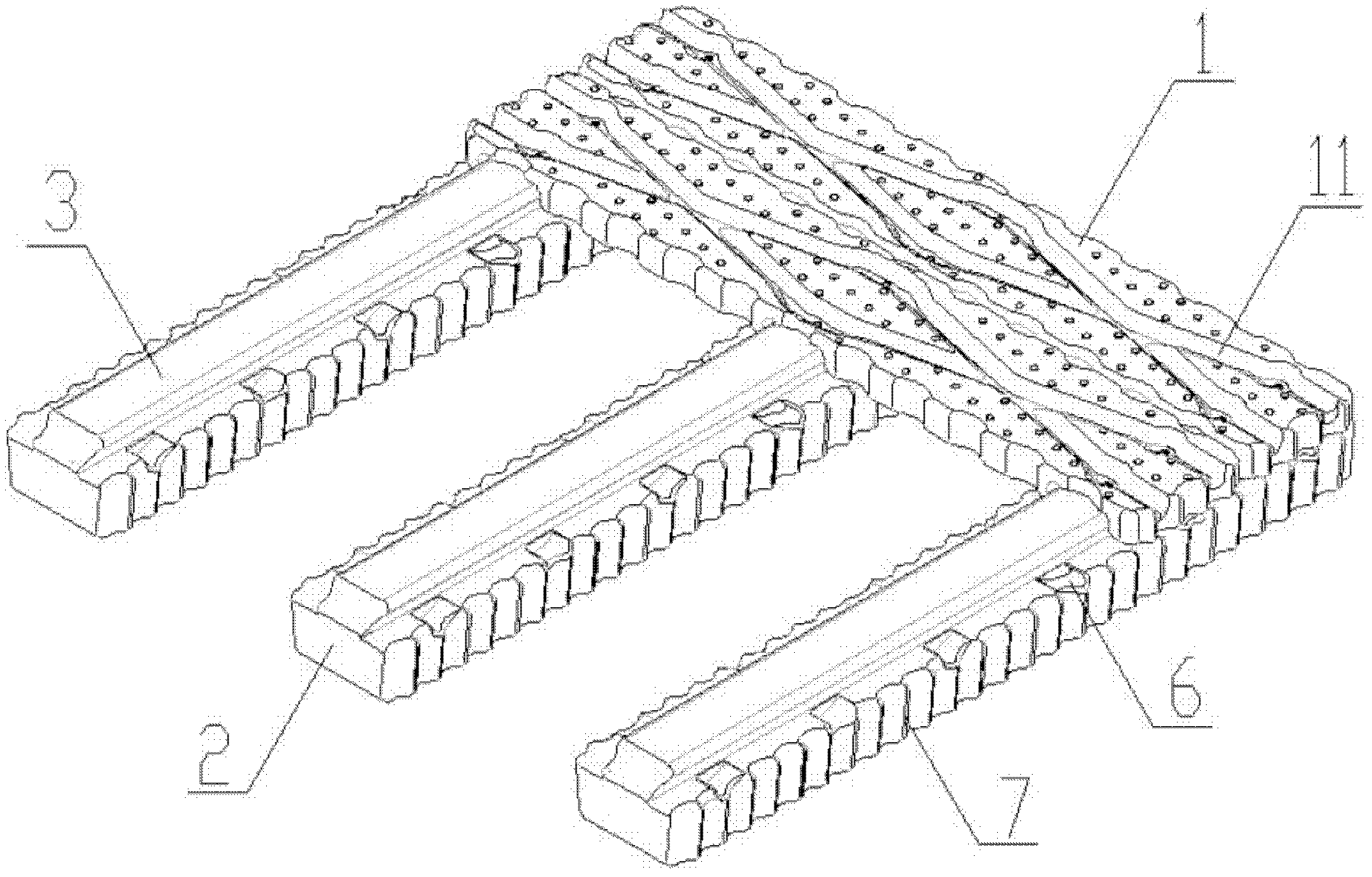

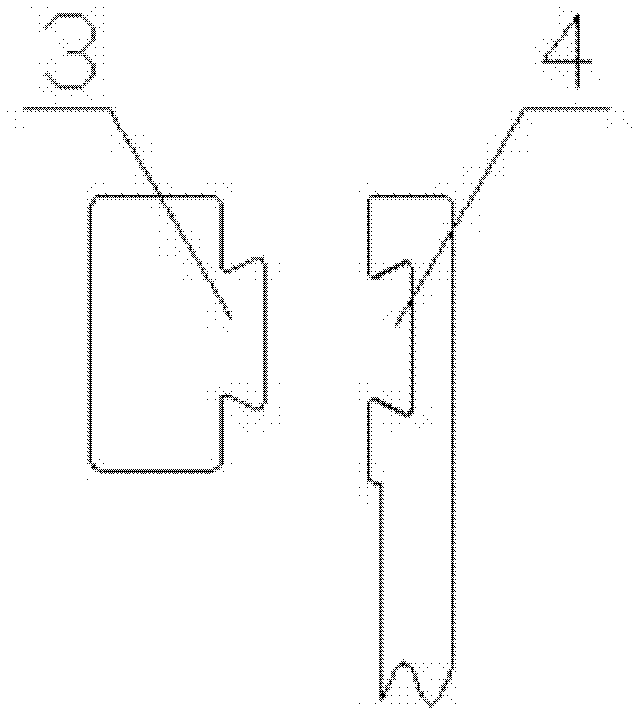

[0023] Such as Figures 1 to 8 As shown, the combined blow molding tray is composed of 6 panel units 1 and 3 legs 2. The panel unit 1 and the legs 2 are in a vertical position relationship with each other. The dovetail tenon 3 and the dovetail Slot 4 is used for plug-in combination. Protruding triangular slopes 5 are provided symmetrically on both sides of the dovetail groove 4 on the panel unit 1 , and concave triangular slopes 6 are provided at corresponding positions on both sides of the dovetail tenon 3 on the leg. The upper surface of the panel unit 1 is provided with intersecting grooves 11, and the surrounding facades of the panel unit 1 and the legs 2 adopt a wave-like structure 7, and the top angle of the wave is arc-shaped. An inwardly recessed elliptical ring reinforcing rib 8 is provided at the bottom of the panel unit 1 .

Embodiment 2

[0025] Such as Figure 9 , Figure 10 Another embodiment of the combined blow molded tray is given. The combined blow molding tray is composed of 6 panel units 1 and 3 legs 2. The relationship between the panel unit 1 and the legs 2 is perpendicular to each other. Dock combination. Protruding hemispherical row structures 9 are arranged symmetrically on both sides of the dovetail groove 4 on the panel unit 1 , and recessed hemispherical structures 10 are arranged on corresponding positions on both sides of the dovetail tenon 3 on the leg. The upper surface of the panel unit 1 is provided with intersecting grooves 11, and the surrounding facades of the panel unit 1 and the legs 2 adopt a wave-like structure 7, and the top angle of the wave is arc-shaped. The bottom of the panel unit 1 is provided with an inwardly recessed diamond-shaped ring 12 reinforcing rib.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com