Method for preparing silicon carbide aluminum-based composite structural member and silicon carbide reinforced preform

A silicon carbide aluminum-based, composite structure technology, applied in the field of composite materials, can solve the problems of difficult removal process, waste gas environmental pollution, long degreasing time, etc., and achieve the effects of avoiding pollution of the environment, uniform density, and cheap molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

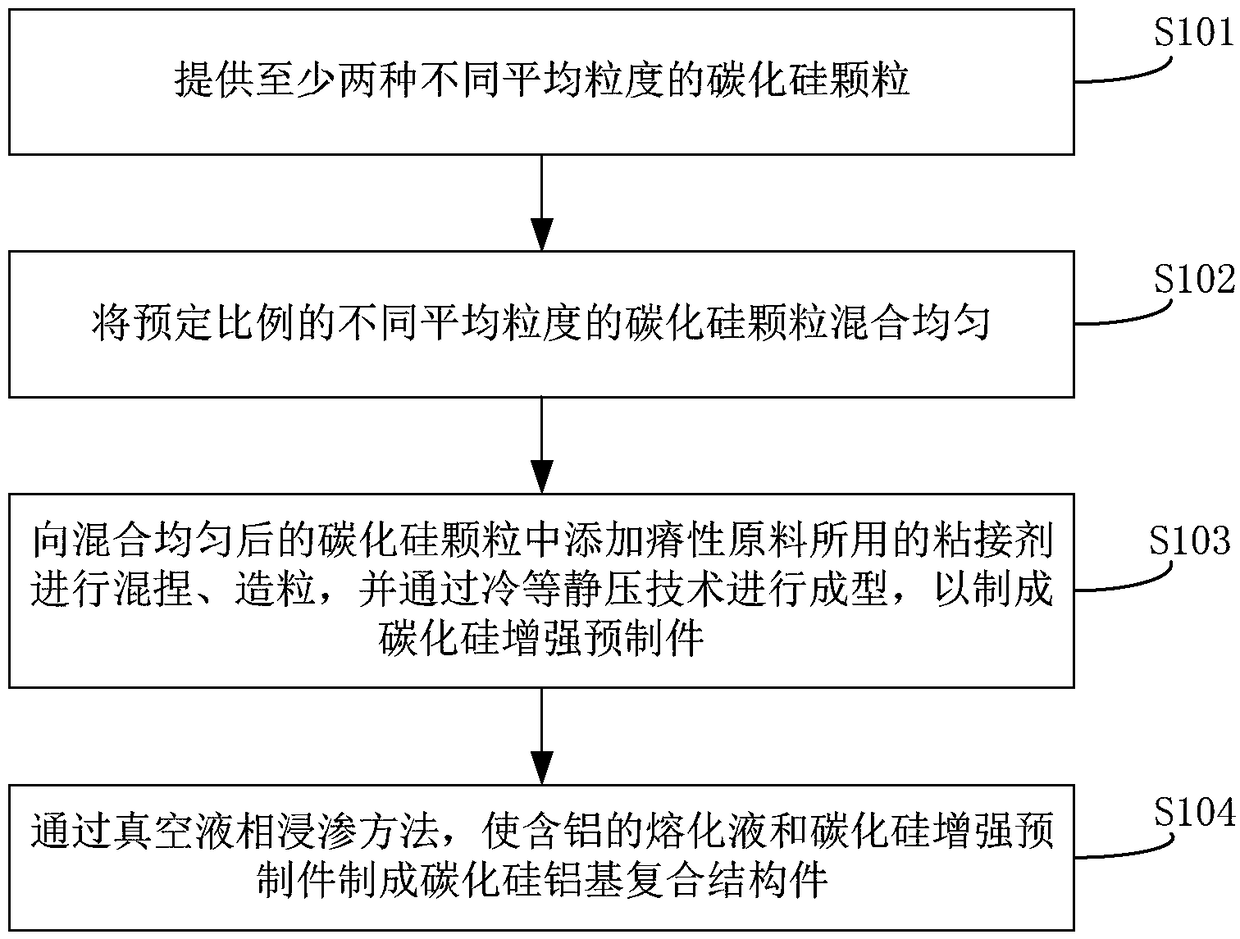

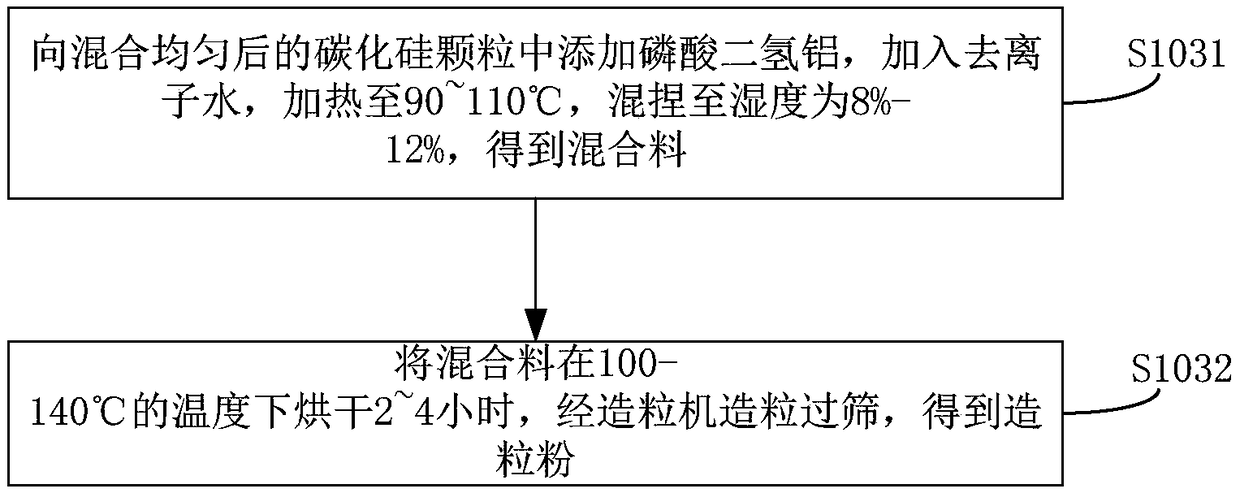

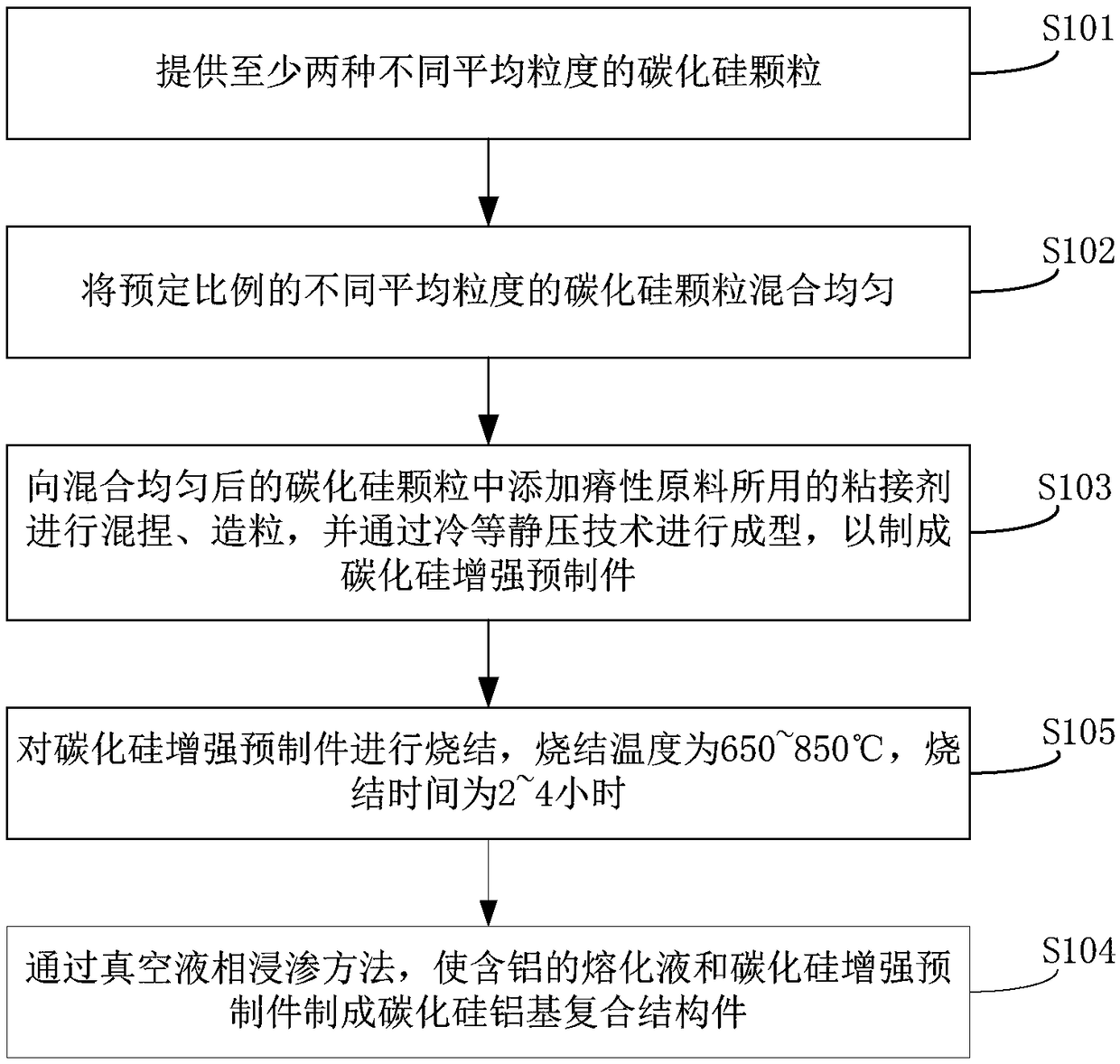

[0024] see figure 1 , figure 1 It is a flow chart of an embodiment of a method for preparing a silicon carbide-aluminum matrix composite structural member of the present application, and the method includes:

[0025] Step S101: providing at least two kinds of silicon carbide particles with different average particle sizes.

[0026]Silicon carbide particles of different particle sizes have different geometric shapes. Usually, the geometric shape of silicon carbide particles is irregular and polyhedral, and some particles have sharp corners. Using an average particle size of SiC particles to prepare SiC preforms may easily cause incomplete filling between the particles, resulting in insufficient strength of the preform, and finally the strength of the AlSiC composite material is not enough to be used as a body structure. In this embodiment, more than two kinds of silicon carbide particles with different average particle sizes are selected, so that SiC particles of different si...

Embodiment 1

[0068] This embodiment is illustrated by taking the preparation of the B-pillar of a car body from an AlSiC composite structure as an example.

[0069] The cross-sectional shape of the traditional B-pillar is relatively complex. It is welded by multiple stamped steel plates. Except for the interior and exterior cladding parts, the B-pillar is generally divided into inner panels, reinforcement panels, and outer panels from the inside to the outside. It is basically a closed thin-walled beam structure. The upper and lower joints connect the B-pillar with the roof side beam and the door frame by welding. To ensure that the B-pillar has sufficient strength, it is even necessary to build a structural model of "outer panel-reinforcement panel-local reinforcement panel-inner panel", and the reinforcement panel structure is usually a small assembly, through the installation of safety belts and doors on the B-pillar The location of locks and other accessories requires high rigidity, an...

Embodiment 2

[0078] This embodiment is illustrated by taking AlSiC composite structural parts as an example to prepare the front longitudinal beam of a car body.

[0079] In automobile structure, thin-walled components stamped from low-carbon steel plates are widely used, and can be welded together with other components through flanging. The cross-section of the traditional car front longitudinal beam is a thin-walled rectangular structure. When a car has a frontal collision, the kinetic energy of the collision is mainly absorbed by the plastic deformation of the front part of the car body, and the front longitudinal beam plays a major role.

[0080] Compared with the low-carbon steel material of the traditional automobile front longitudinal beam, the aluminum-silicon carbide composite structure has higher yield strength and energy absorption capacity, and at the same time achieves the purpose of greatly reducing weight. Comprehensively considering the energy absorption capacity, collisio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com