Special grinding fluid for grinding of silicon carbide ceramic by diamond grinding wheels and preparation method of special grinding fluid

A silicon carbide ceramic and diamond grinding wheel technology, which is used in the petroleum industry, base materials, additives, etc., can solve the problems of deep subsurface damage layer depth on the workpiece surface, easy graphitization of diamond abrasive grains, and high grinding temperature of diamond grinding wheels. Good cooling performance and anti-rust performance, the effect of reducing the depth of surface damage and reducing the surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

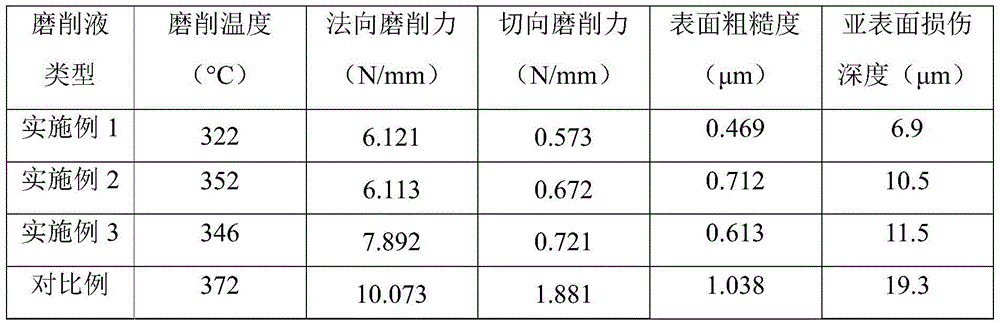

Examples

Embodiment 1

[0035] A special grinding fluid for grinding silicon carbide ceramics with a diamond grinding wheel, characterized in that the mass percent content of each component is: 5.5% fatty acid methyl ester polyoxyethylene ether, 2.8% alkyl synthetic alcohol alkoxy compound , 2.3% tungsten disulfide, 4.3% cyclopentasiloxane, 3.6% extreme pressure antiwear agent, 2.8% corrosion inhibitor, 3.1% friction modifier and 75.6% deionized water .

[0036] The steps to make it are as follows:

[0037] Step 1, according to the mass percent content of each component, be 5.5% fatty acid methyl ester polyoxyethylene ether, 2.8% alkyl synthetic alcohol alkoxy compound, 2.3% tungsten disulfide, 4.3% cyclopentamethylene Base siloxane, 3.6% extreme pressure antiwear agent, 2.8% corrosion inhibitor, 3.1% friction modifier and 75.6% deionized water weigh raw materials;

[0038]Step 2. Mix tungsten disulfide and zinc dibenzyl dithiocarbamate evenly, add an appropriate amount of deionized water, and heat...

Embodiment 2

[0047] A special grinding fluid for diamond grinding wheel grinding silicon carbide ceramics, characterized in that the mass percent content of each component is: 6.2% fatty acid methyl ester polyoxyethylene ether, 2.9% alkyl synthetic alcohol alkoxy compound , 2.5% tungsten disulfide, 4.4% cyclopentasiloxane, 3.5% extreme pressure antiwear agent, 2.3% corrosion inhibitor, 2.5% friction modifier and 75.7% deionized water .

[0048] The steps to make it are as follows:

[0049] Step 1, according to the mass percent content of each component, be 6.2% fatty acid methyl ester polyoxyethylene ether, 2.9% alkyl synthetic alcohol alkoxy compound, 2.5% tungsten disulfide, 4.4% cyclopentamethylene Base siloxane, 3.5% extreme pressure antiwear agent, 2.3% corrosion inhibitor, 2.5% friction modifier and 75.7% deionized water weigh raw materials;

[0050] Step 2. Mix tungsten disulfide and zinc dibenzyl dithiocarbamate evenly, add an appropriate amount of deionized water, raise the temp...

Embodiment 3

[0059] A special grinding fluid for grinding silicon carbide ceramics with a diamond grinding wheel, characterized in that the mass percent content of each component is: 4.8% fatty acid methyl ester polyoxyethylene ether, 2.5% alkyl synthetic alcohol alkoxy compound , 2.2% tungsten disulfide, 4.2% cyclopentasiloxane, 3.7% extreme pressure antiwear agent, 3% corrosion inhibitor, 3.5% friction modifier and 76.1% deionized water .

[0060] The steps to make it are as follows:

[0061] Step 1, according to the mass percent content of each component, be 4.8% fatty acid methyl ester polyoxyethylene ether, 2.5% alkyl synthetic alcohol alkoxy compound, 2.2% tungsten disulfide, 4.2% cyclopentamethylene Base siloxane, 3.7% extreme pressure antiwear agent, 3% corrosion inhibitor, 3.5% friction modifier and 76.1% deionized water weigh raw materials;

[0062] Step 2. Mix tungsten disulfide and zinc dibenzyl dithiocarbamate evenly, add an appropriate amount of deionized water, heat up to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com