Teflon rubber roller and production method thereof

A technology of Teflon rubber and rubber roller, which is applied in the direction of coating, etc., to achieve the effect of reasonable process, improved service life and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

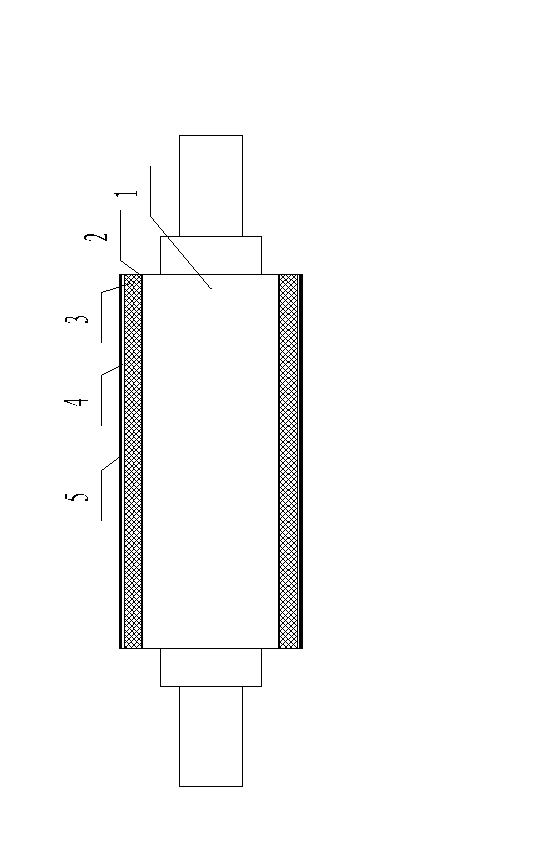

[0027] As shown in the accompanying drawings, the Teflon rubber roller includes a roller core 1 and a rubber layer 3 coated on the roller core, and is characterized in that: the surface of the rubber layer is provided with a Teflon coating 5 .

[0028] Shown in conjunction with accompanying drawing, the production method of this Teflon rubber roller comprises the following steps:

[0029] (1) The roller core 1 is welded by seamless steel pipe, steel plate and round steel, and is finished by lathe to meet the dynamic balance requirements;

[0030] (2) Clean the roller surface of the roller core 1 with a laser cleaning system to remove rust and oil stains on the roller surface, and at the same time create a microscopic capillary structure on the roller surface to improve the bonding strength between the rubber and the roller surface;

[0031] (3) Brush t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com