An iron ore dry powder magnetic separation process and equipment

A technology of iron ore and dry powder, applied in magnetic separation, solid separation, chemical instruments and methods, etc., to achieve the effect of improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] a. Use the jaw crusher to crush the ore to a diameter of Φ30-40mm;

[0020] b. Grind the obtained ore to 100 mesh through a centrifugal vibrating mill with a model number of 2MGZ450, so as to disintegrate and peel off the continuous ore powder particles;

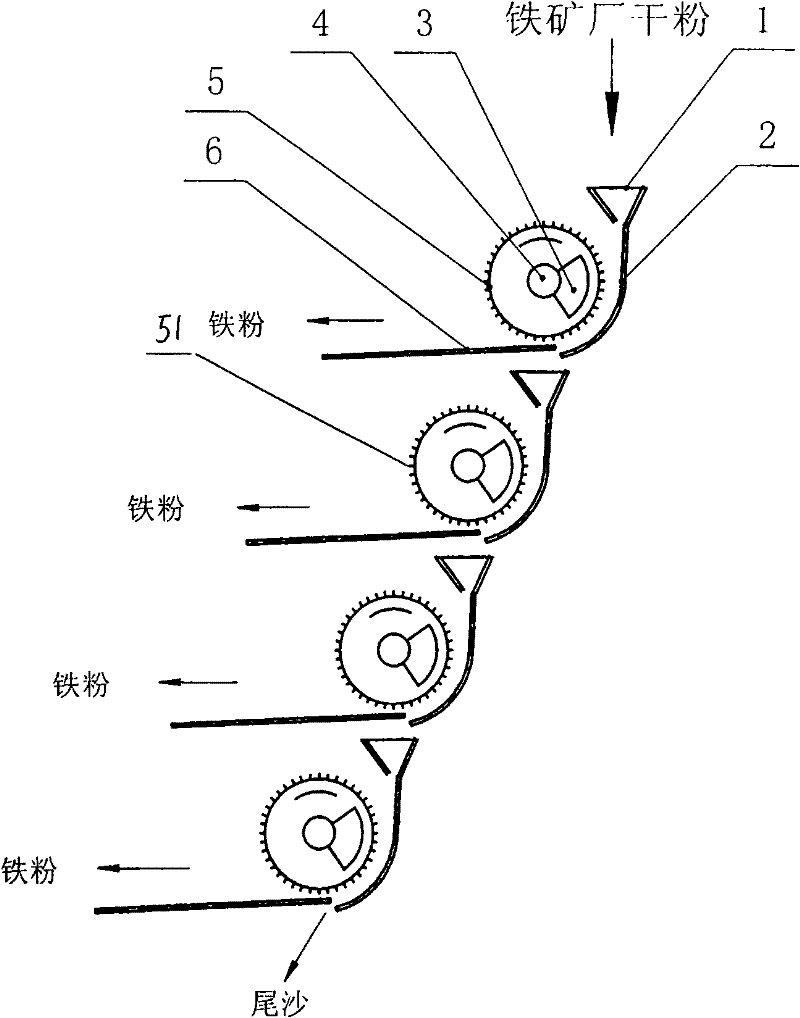

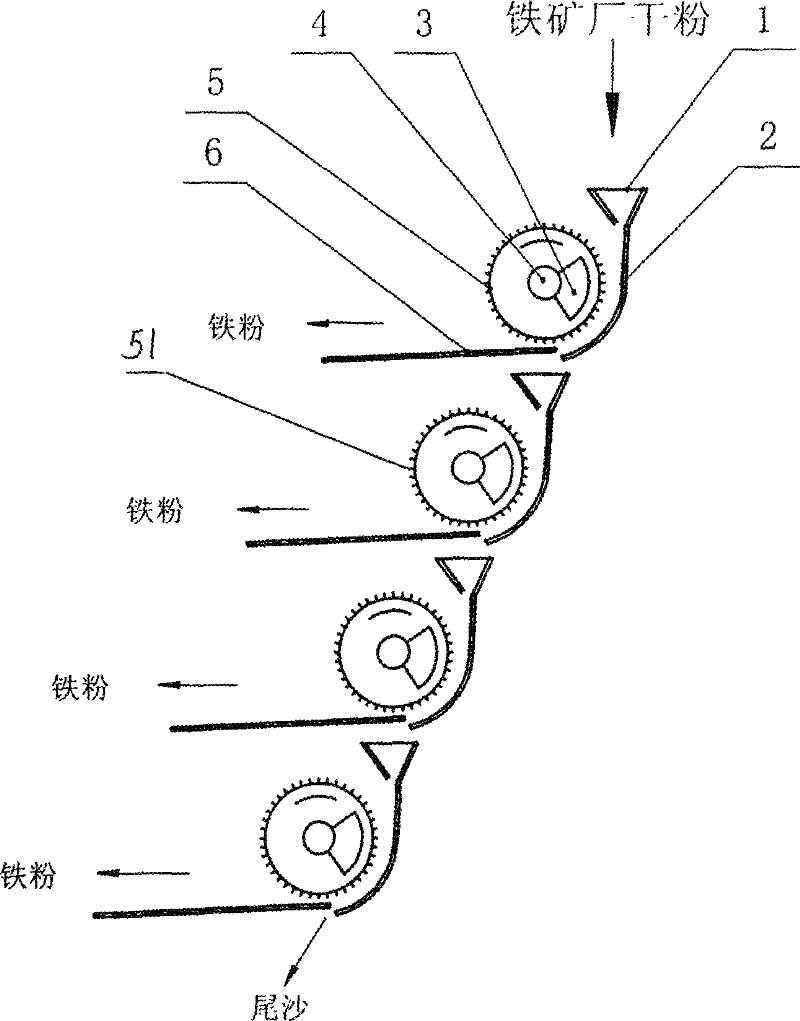

[0021] c. Use iron ore dry powder magnetic separator to select iron fine powder. Such as figure 1 As shown, the dry powder magnetic separator is provided with four consecutively connected magnetic separation devices on the frame; the magnetic separation device includes a magnetic separation roller and a logistics plate; A fixed shaft 4 is arranged on the fixed shaft 4, and a roller 5 is connected to the fixed shaft 4 through a bearing. On the fixed shaft in the roller, an electromagnet 3 with a fan-shaped cross section is arranged in the axial direction, and the electromagnet and the roller are electrically connected with the controller; The rotation is driven by the power transmission device. The rotation speed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com