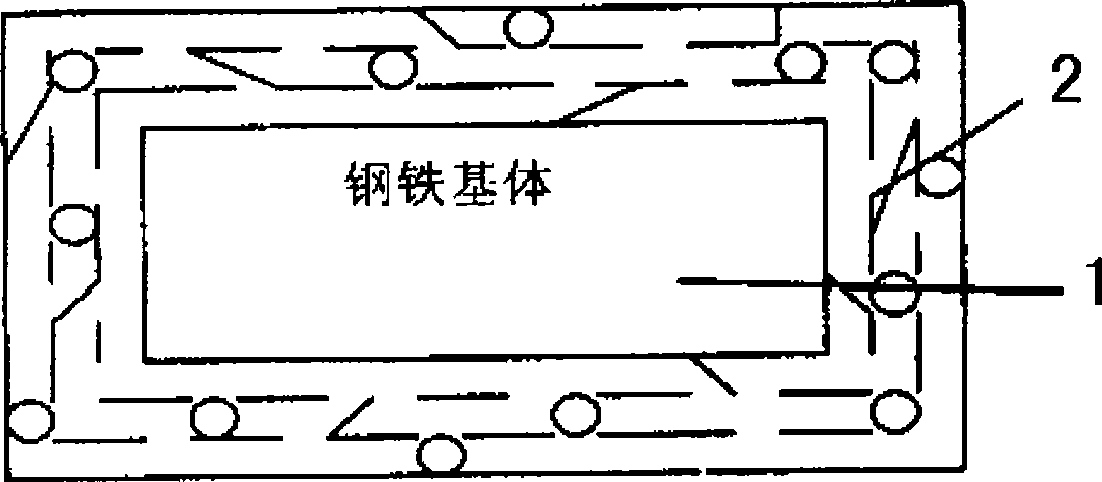

Method for preparing composite organic protective film on surface of steel

A technology for steel surface and protective film, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc. It can solve the problems of low friction reduction, lack, affecting the performance of organic protective film, etc., and achieve the friction coefficient. The effect of reducing, strong binding, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

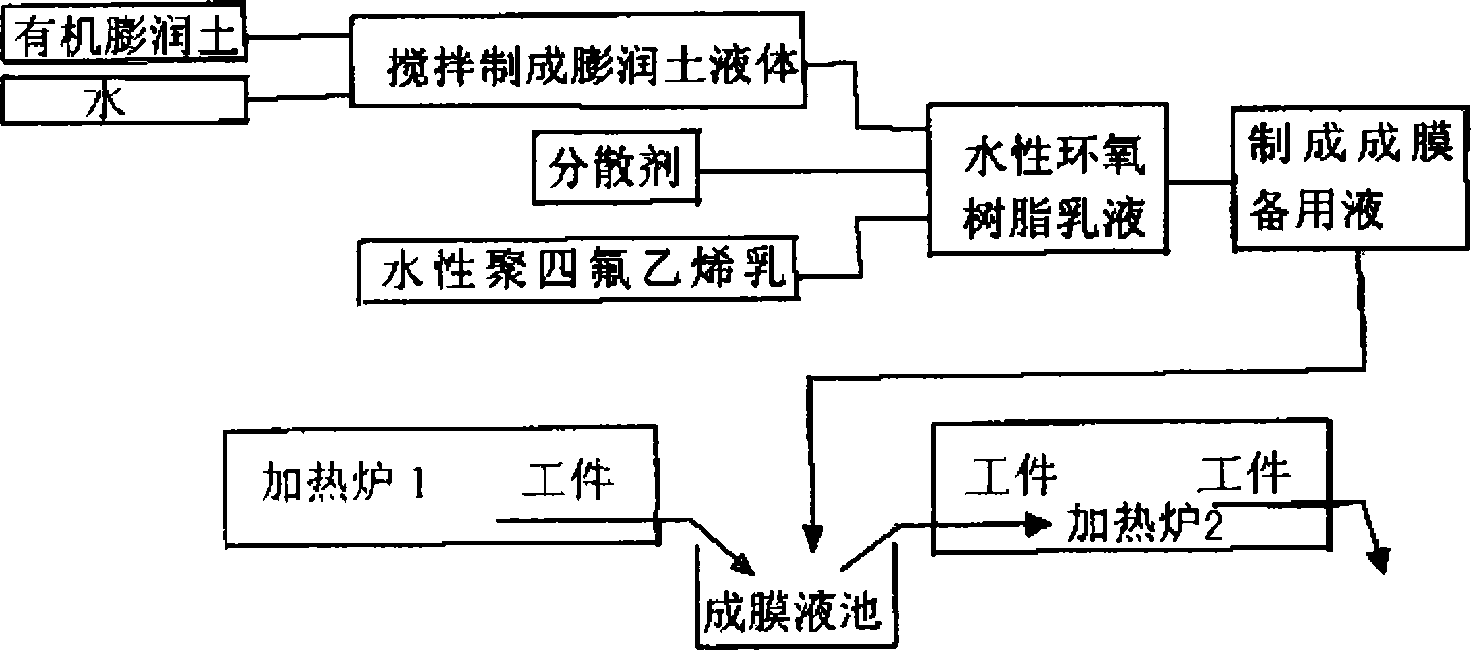

[0023] control figure 2 , add 40 grams of 1500 mesh organic bentonite in 100 milliliters of water, stir well and place it for 1 hour for later use; add 2 grams of water-based carbon black slurry in 100 grams of water-based epoxy resin emulsion with a solid content of 50% (according to color requirements, you can Add the color paste of other colors), 1 gram of trisodium phosphate, 20 grams of prepared organic bentonite liquid, 50 grams of 50% water-based polytetrafluoroethylene emulsion, stir to make epoxy resin film-forming liquid for subsequent use. Adjust the concentration of the film-forming liquid according to the size of the workpiece and the heating temperature. Film-forming liquid: tap water = 1:5. Example 1 workpiece is a Φ20 nut. Heating temperature 400°C±10°C, keep warm for 20 minutes, take out the workpiece and immerse it in the film-forming solution whose concentration has been adjusted for 10 seconds, then take it out, and put the film-formed workpiece back int...

Embodiment 2

[0026] The steel workpiece is a Φ40 nut, the heating temperature is 400°C±10°C, and the temperature is kept for 20 minutes. The film-forming liquid:tap water=1:7.

[0027] control figure 2 , first, heat the workpiece nut at a heating temperature of 400°C±10°C, keep it warm for 20 minutes, then take out the workpiece and immerse it in the film-forming liquid pool whose concentration has been adjusted for 10 seconds. The workpiece after the first film formation is put back into the heating furnace for heating at a heating temperature of 150°C±10°C for 30 minutes, then the workpiece is taken out and air-cooled to obtain an organic protective film with a film thickness of about 20um.

[0028] The organic protective film of this embodiment is soaked in 5% hydrochloric acid solution for 3 days without peeling, and the corrosion point is less than 1 / square centimeter. Soaked in 5% sodium hydroxide aqueous solution for 7 days, there is no abnormality, the friction coefficient is red...

Embodiment 3

[0030] The steel workpiece is a Φ40 nut, the heating temperature is 500°C±10°C, and the temperature is kept for 20 minutes. The film-forming liquid: tap water = 1:8;

[0031] control figure 2 , first, heat the workpiece nut at a heating temperature of 400°C±10°C, keep it warm for 20 minutes, then take out the workpiece and immerse it in the film-forming liquid pool whose concentration has been adjusted for 10 seconds. The workpiece after the first film formation is put back into the heating furnace 1 for heating, the heating temperature is 300°C±10°C, and the temperature is kept for 15 minutes. The workpiece is taken out and cooled in air or immersed in water, and then taken out to obtain an organic protective layer with a film thickness of about 20um. membrane.

[0032] The organic protective film of this embodiment is soaked in 5% sodium chloride solution for 20 days without peeling, and the corrosion point is less than 1 / square centimeter. Soaked in 5% sodium hydroxide a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com