Anti-static shoe sole

An anti-static and anti-scorch agent technology, which is applied in the field of shoe soles, can solve the problems of affecting the wear resistance of shoes, the sole cannot be applied, and the requirements are not up to standard, etc., and achieve the effects of easy access, elastic properties up to standard, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

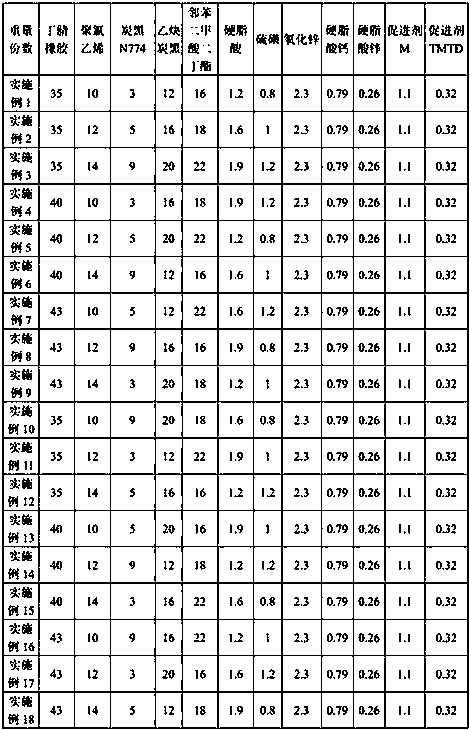

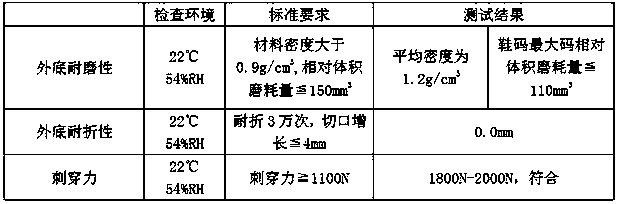

Method used

Image

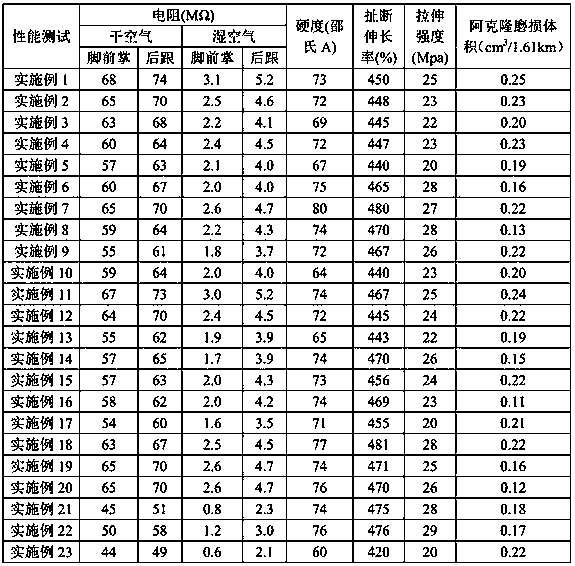

Examples

Embodiment 19

[0055] An antistatic shoe sole, the difference between embodiment 19 and embodiment 14 is that 0.03 part of N-cyclohexylthiophthalimide is added.

Embodiment 20

[0057] An antistatic shoe sole, the difference between embodiment 20 and embodiment 14 is that 9 parts of nanometer antiwear agents are also added.

Embodiment 21

[0059] A kind of antistatic shoe sole, the difference between embodiment 21 and embodiment 14 is that 12 parts of acetylene carbon black are replaced with 10 parts of acetylene carbon black and 2 parts of graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com