Phosphorous epoxy resin curing agent and preparation method thereof

An epoxy resin curing and solvent technology, which is applied in the field of phosphorus-containing epoxy resin curing agent and its preparation, can solve the problems of easy fire, application limitation, low oxygen index of epoxy resin, etc., and achieve simple post-treatment process and high production efficiency. Simple conditions, high product purity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

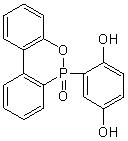

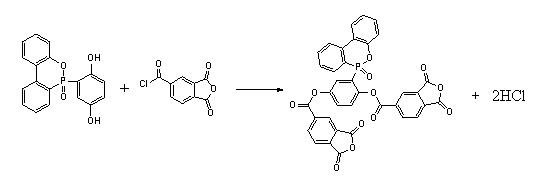

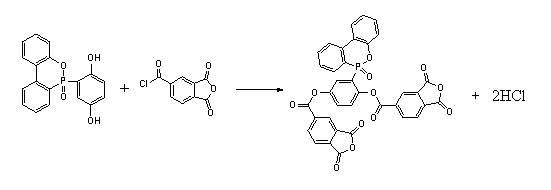

Image

Examples

Embodiment 1

[0026] Add ODOPB (3.243g, 0.01mol) and trimellitic anhydride acid chloride (4.220g, 0.02mol) to a 250ml four-necked flask equipped with a thermometer, nitrogen gas introduction, magnetron, reflux condenser and tail gas absorption device, and then add 100ml Toluene, heated to 110°C with stirring, reacted for 5 hours, and continued to pass N after the reaction 2 Bring to room temperature. Then the mixed solution was stirred and poured into 200ml of petroleum ether, a white precipitate was precipitated, filtered under reduced pressure, and the filter cake was washed with 100ml of petroleum ether, and dried at 120°C for 6 hours to obtain 3.106g of product BPA-ODOPE, the yield 46.2%, purity.

Embodiment 2

[0028] Add ODOPB (3.243g, 0.01mol) and trimellitic anhydride acid chloride (6.320g, 0.03mol) to a 250ml four-necked flask equipped with a thermometer, nitrogen gas introduction, magnetron, reflux condenser and tail gas absorption device, and then add 100ml Xylene, heated to 140°C under stirring, reacted for 5 hours, and continued to pass N after the reaction 2 Bring to room temperature. Then the mixed solution was stirred and poured into 200ml of petroleum ether, a white precipitate was precipitated, filtered under reduced pressure, and the filter cake was washed with 100ml of petroleum ether, and dried at 120°C for 6 hours to obtain 5.359g of product BPA-ODOPE, the yield 79.7%, purity.

Embodiment 3

[0030] Add ODOPB (3.243g, 0.01mol) and trimellitic anhydride acid chloride (6.320g, 0.03mol) to a 250ml four-necked flask equipped with a thermometer, nitrogen gas introduction, magnetron, reflux condenser and tail gas absorption device, and then add 100ml Chlorobenzene, heated to 130°C with stirring, reacted for 5 hours, and continued to pass N after the reaction 2 Bring to room temperature. Then the mixed solution was stirred and poured into 200ml of petroleum ether, a white precipitate was precipitated, filtered under reduced pressure, and the filter cake was washed with 100ml of petroleum ether, and dried at 120°C for 6 hours to obtain 5.554g of product BPA-ODOPE, the yield 82.6%, purity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com