Ultralow temperature polyvinyl chloride (PVC) modified insulating sheath cable material and preparation method thereof

A technology of polyvinyl chloride and insulating sheath is applied in the field of materials, which can solve problems such as high cost and achieve the effects of low embrittlement temperature, abundant raw material sources and convenient industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

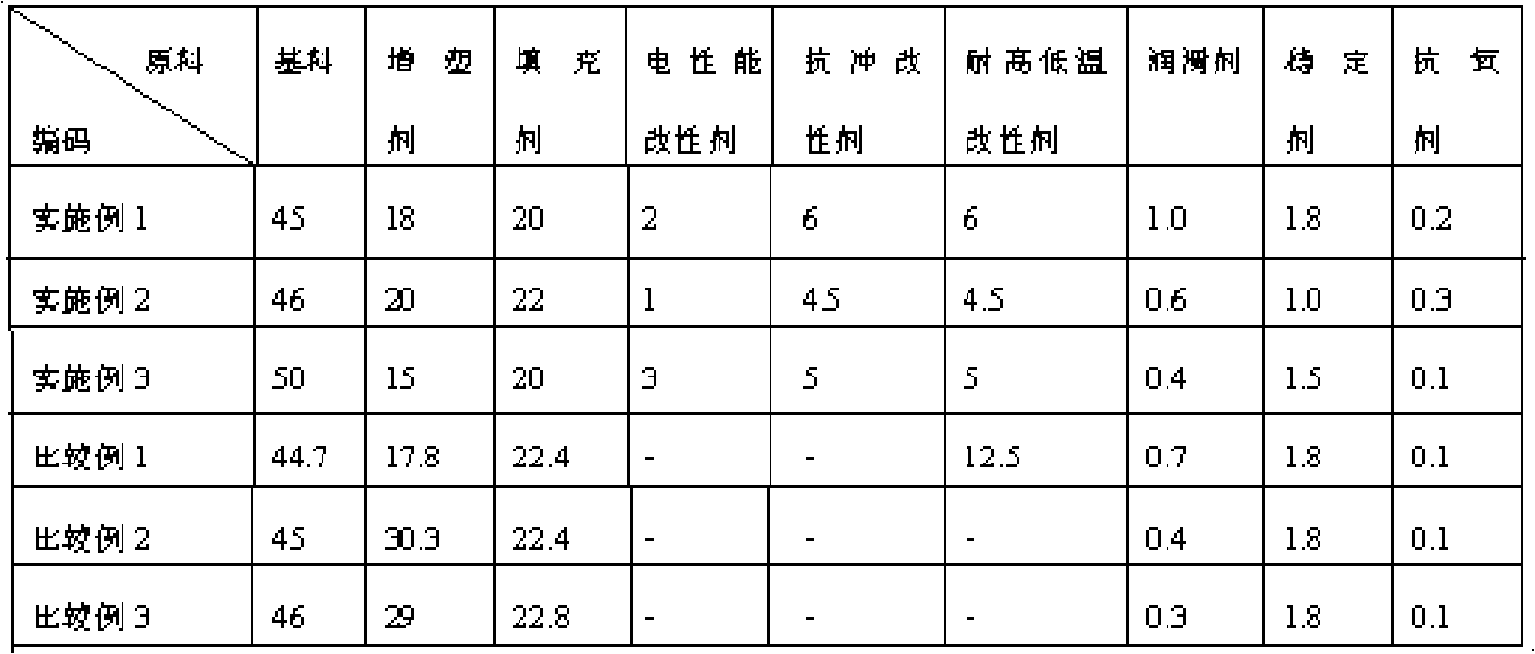

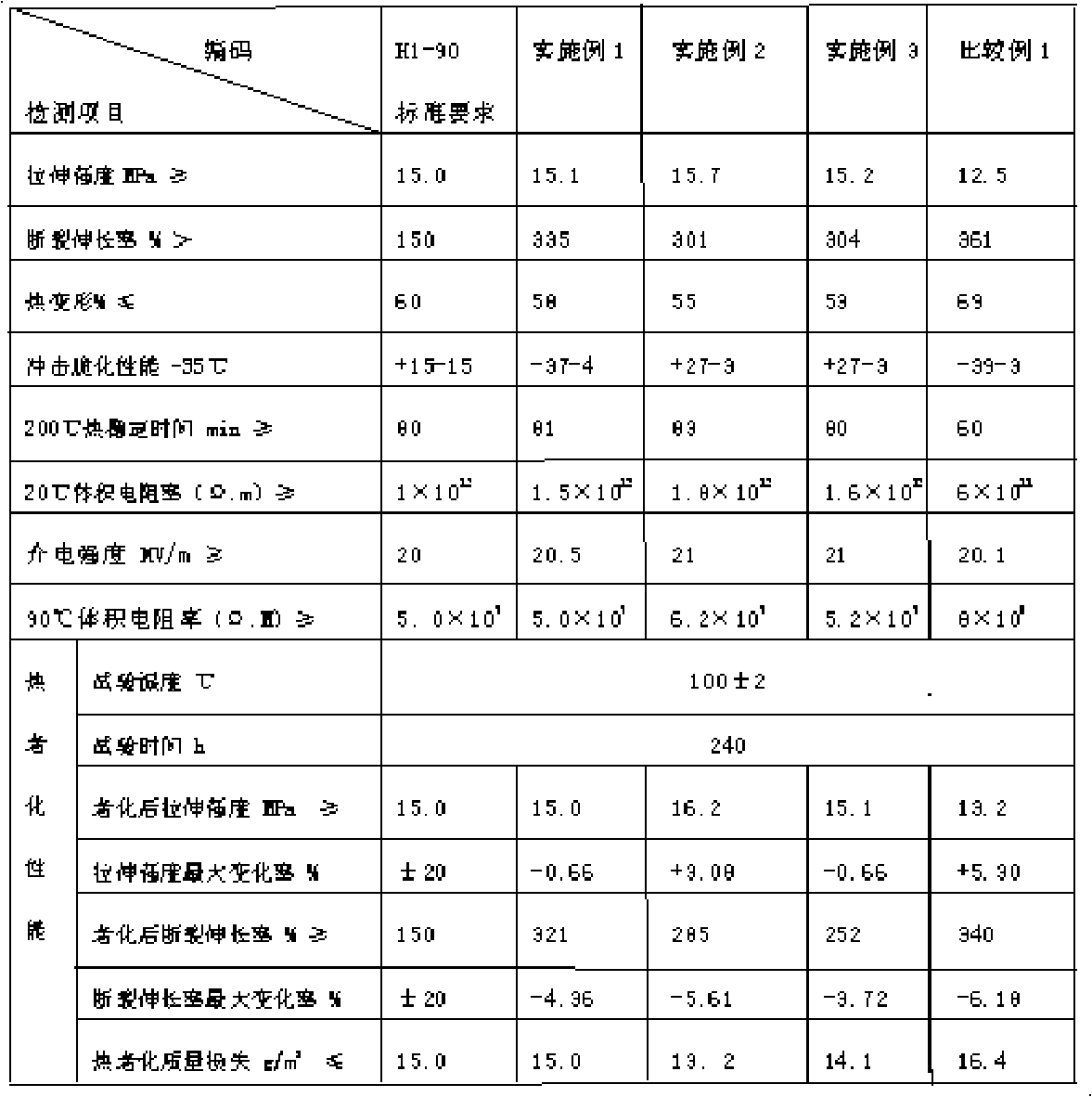

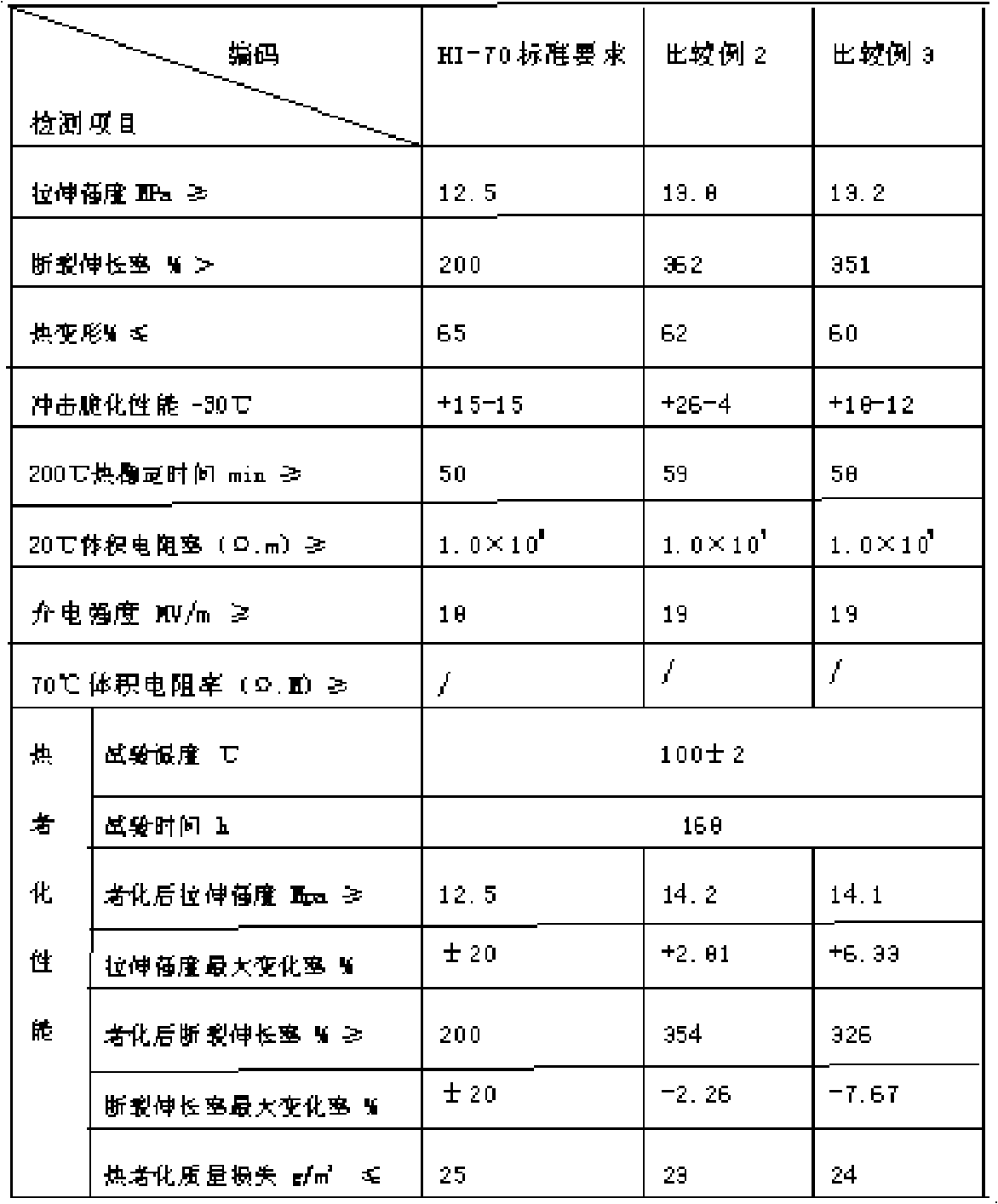

Embodiment 1

[0028] Prepare the raw materials according to formula 1 in Table 1, the base material is type 3 polyvinyl chloride resin, the plasticizer is a 1:1 mixture of dioctyl phthalate and dioctyl terephthalate, and the filler is ultrafine reactive weight Calcium carbonate, the electrical performance modifier is activated superfine calcined kaolin, the impact-resistant high and low temperature modifier is a mixture of polyvinyl chloride 135A and ethylene-vinyl acetate-carbon monoxide terpolymer, and the lubricant is G-3200 Composite lubricant and oxidized polyethylene wax mixture (0.6:0.4), antioxidant is bisphenol A, stabilizer is composite lead.

[0029] Preparation of cable material:

[0030] 1. Feeding and mixing:

[0031] Put the prepared raw materials into the blender for mixing and stirring, and discharge the material when the material temperature reaches 90-100°C, then put it into a low-temperature mixer for cooling while stirring, and discharge the material when the temperatu...

Embodiment 2

[0041] Prepare raw materials according to formula 2 in Table 1, the plasticizer is a mixture of dioctyl terephthalate and trioctyl trimellitate, and the impact modifier for high and low temperature resistance is polyvinyl chloride 135A and ethylene vinyl acetate carbon monoxide ternary A 1:1 mixture of copolymers, the lubricant is a mixture of G-3200 composite lubricant and oxidized polyethylene wax (0.1:0.5).

[0042] The mixing time is 20min, and other operations are the same as in Example 1.

Embodiment 3

[0044] Prepare raw materials according to formula 3 in Table 1, the plasticizer is a mixture of dioctyl phthalate, dioctyl terephthalate and trioctyl trimellitate, and the lubricant is G-3200 composite lubricant and oxidized polyethylene Wax mixture (0.2:0.2).

[0045] The mixing time is 18min, and other operations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com